.jpg)

Slag grinding production line is a specialized system that processes metallurgical byproducts (such as blast furnace slag and steel slag) into high-value-added slag fine powder through drying, grinding, and separation processes.

The main equipment of this production line includes a C110 jaw crusher, a HP300 cone crusher, a 2YK3080 vibrating screen, and a VSI1263 sand-making machine.

The stone crushing plant is specially designed to produce medium and large-sized sand and gravel aggregates. The core processing capacity reaches 800 tons/hour. It is suitable for hard stones such as granite and basalt. The finished product is adjustable (0-5mm machine-made sand to 20-40mm aggregate).

This stone crushing plant is specially designed to produce medium and large-sized sand and gravel aggregates. The core processing capacity is up to 500 t/h. It is suitable for hard stones such as granite and basalt. The finished product is adjustable (0-5mm machine-made sand to 20-40mm aggregates).

Recommended core equipment for large crushing stations (350-450 t/h), including jaw crusher, cone crusher, and vibrating screening type, to improve production capacity and finished product quality!

200-300 t/h stone crushing station can efficiently crush granite, limestone, basalt, pebbles, and other hard rocks and construction waste, suitable for sand and gravel aggregates, mining, and solid waste recycling.

The main equipment of this crushing plant is a C110 jaw crusher and a PFW1320 Impact crusher or CS250 cone crusher.

180-220 t/h stone crushing station, equipped with jaw crusher + cone crusher + impact crusher, suitable for crushing granite and basalt, finished product 0-31.5mm adjustable.

The main equipment of this crushing plant is a PE750x1060 jaw crusher and a PFW1320 Impact crusher.

The main equipment of this crushing plant is a PE600x900 jaw crusher and CS110 cone crusher or PYB1200 cone crusher.

The main equipment of this crushing plant is a PE600x900 jaw crusher and PF1214 Impact crusher.

The main equipment of this crushing plant is PE500x750 jaw crusher and CS75 Simons cone crusher.

30-60tph crushing production line is usually used for the crushing of medium hardness ores (such as limestone, granite, basalt) or construction waste.

This calcium carbonate grinding line employs energy-efficient mills (e.g., Raymond, vertical, ball mills) to produce 200-3000 mesh powder, meeting diverse industry fineness requirements.

The bentonite grinding production line is a production process specifically for bentonite processing. Its main purpose is to convert bentonite raw materials into high-quality bentonite powder.

The kaolin grinding production line is a complete production process specially used to process kaolin raw materials into kaolin powder. Kaolin is a non-metallic mineral widely used in ceramics, papermaking, coatings, rubber and other fields.

Talc's excellent properties make it vital in plastics, coatings, ceramics, and cosmetics. An efficient, intelligent grinding line ensures high fineness, purity, and production capacity in mineral processing.

This production line transforms barite ore into fine powder with simple setup, stable operation, high yield, and low energy consumption. The finished product meets precise fineness standards for mining, construction, metallurgy, and industrial applications.

We provide comprehensive solutions for calcite grinding lines, including Raymond mills, ultrafine vertical mills, and other equipment. We also provide a detailed introduction to the calcite powder processing process (coarse crushing - grinding - grading - packaging), suitable for fineness requirements of 325-3000 mesh.

Potash feldspar (KAlSi₃O₈) is vital for the ceramics/glass industries. Its powder fineness affects product quality, making ceramic ball mill production lines essential for high-purity processing.

Limestone grinding production line typically includes crushing, grinding, grading, and collection to ensure uniform fineness and stable output of the finished product.

The main equipment of this production line includes a pe750x1060 jaw crusher, a CS220 cone crusher, a 3YK1860 vibrating screen, and a VSI9526 sand-making machine.

The main equipment of this production line includes a pe500x750 jaw crusher, a CS75 cone crusher, a 3YK1548 vibrating screen, and a VSI7611 sand-making machine.

The main equipment of this production line includes a pe600x900 jaw crusher, a PYB1200cone crusher, a 2YK2475 vibrating screen, and a VSI1150 sand-making machine.

Dolomite grinding production lines are key equipment for increasing the added value of resources. Choosing an efficient, energy-saving, and environmentally friendly grinding solution will give your products a competitive edge in the market.

Gypsum grinding production line is a complete set of equipment system specially used to process natural gypsum ore or industrial by-product gypsum into gypsum powder of different fineness.

The gold ore processing production line has become the core competitiveness of modern gold mining development with its five major advantages: high recovery rate, automation, environmental protection, flexible adaptation, and economic benefits. Whether it is a large mine or a small and medium-sized concentrator, a scientifically designed production line can significantly increase gold production and reduce operational risks.

Gold ore CIP process (carbon leaching gold method) is a gold extraction process widely used in mineral processing plants. It involves dissolving gold from an ore or concentrate into a cyanide solution and then adsorbing the dissolved gold onto activated carbon.

Subsequently, the activated carbon is separated from the slurry and the gold is desorbed from the activated carbon for further processing.

Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, the CIL process lowers the gold mining operation cost and increases the gold recovery rate to 99%, which is the first choice of modern gold mining and gold beneficiation plants.

CIL mainly applies to the process of above 1g/t grade gold ore and gold ore with large bearing ore volume: silver, platinum, copper, etc. And CIL has a better performance in extracting these minerals at the same time.

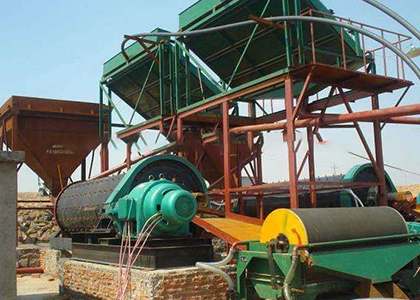

Magnetite is mostly granular aggregates with strong magnetism and wide distribution. According to the different types of iron-bearing minerals, magnetite can be divided into single magnetite ore and mixed magnetite ore, the magnetite iron ore beneficiation process is also different.

In general, single magnetite ore adopts a low-intensity magnetic separation method, and mixed magnetite ore adopts the combined process of multiple beneficiation methods, including magnetic separation, flotation separation, gravity separation, and so on.

The Hematite/Magnetite processing line adopts stage grinding and stage separation for high separation efficiency. The combination of strong magnetic separation and reverse flotation process ensures the concentrate grade and environmental protection.

Hematite/Magnetite separation process is suitable for complex structure hematite ore, such as hematite ore and impurities with uneven distribution of particle size, hematite ore with large content of fine particles, hematite ore with a small amount of magnetite, and the gangue minerals containing quartz or kaolin.

Flotation is one of the commonly used methods for copper ore beneficiation. There are different types of copper ores in nature, and there are many kinds of copper ores that can be applied to flotation technology. The following will introduce you to the general process flow of copper ore flotation technology, the types of copper ore suitable for flotation technology, and the equipment used in the flotation process.