The main metal minerals include chalcopyrite, the second is bornite, malachite, and a small amount of chalcocite. The main gangue mineral is dolomite and carbonation of dolomite, the second is quartz, calcite, and feldspar. Copper mineral is mainly paraded in dolomite and carbonation of dolomite. The block of copper carbide minerals is mainly in massive, spot, and scattered shapes. Oxidized ore is output in power and thin film. The particle size of chalcopyrite is 0.03-0.2mm.

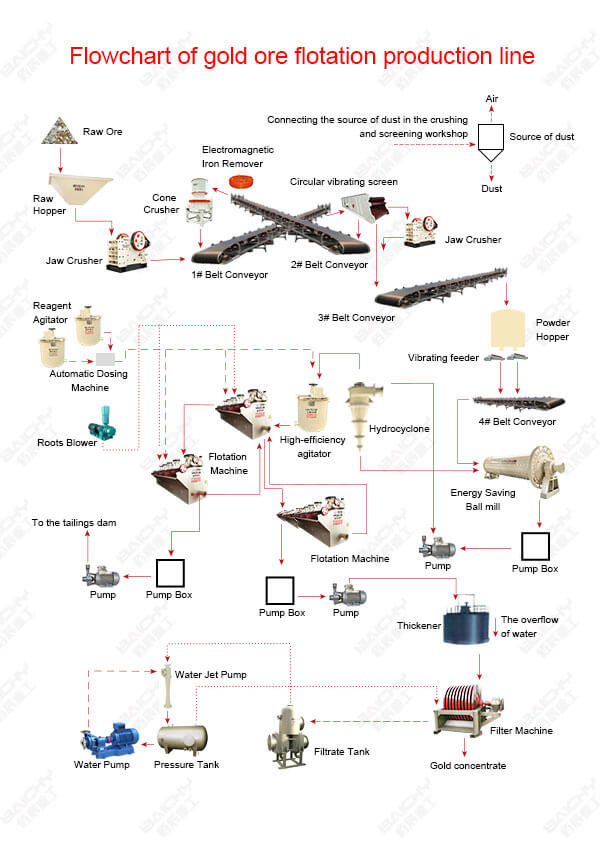

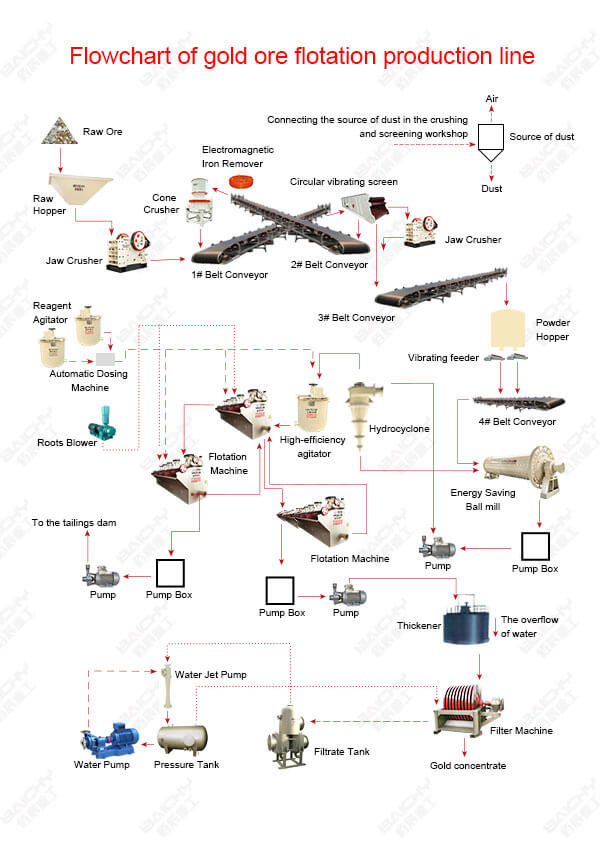

The ore has medium hardness, whose density is 2.85t/m³. On the basic, copper process plant line is adopted in crushing, grinding, and flotation. In crushing, a stage open circuit is adopted, and the final crushing particle size, bigger than 18mm is less than 10%. Two-stage continuous grinding is adopted in the grinding part. In the first stage, the grinding concentrate is 75~80%, and the overflow concentrate is higher than 44%. In the flotation process, there are two rough selections and two scavenges. At the first stage of the rough copper recovery process, coarse and concentrated copper ore are produced.