The three-drum dryer is particularly suitable for medium and large-scale production needs due to its energy-saving, high efficiency, and environmental protection. Long-term use can significantly reduce operating costs and is one of the preferred equipment for modern industrial drying. When choosing, you need to match the model according to the material characteristics, output, and environmental protection requirements.

• Three-pass structure: The material circulates repeatedly in three concentric drums (inner drum → middle drum → outer drum), which prolongs the contact time between hot air and materials, and the heat energy utilization rate can reach more than 80%, which is 30%~50% more energy-saving than the single-drum dryer.

• Insulation design: The multi-layer drum structure reduces heat loss and fuel consumption.

Three-drum drying delivery

Three-drum drying delivery

Three-drum drying delivery

Three-drum drying delivery

The three-drum dryer adopts advanced drying technology, which can greatly improve drying efficiency and reduce energy consumption. Compared with traditional drying equipment, its energy-saving effect can reach more than 30%.

The three-drum dryer is suitable for drying various materials, such as slag, clay, coal, iron powder, etc. At the same time, it can also be adjusted and optimized according to the characteristics and drying requirements of the materials to meet the needs of different industries.

The three-drum dryer adopts an advanced control system, which can realize automatic operation.

The waste gas generated by the three-drum dryer during the drying process can be discharged after treatment, which meets the national environmental protection requirements.

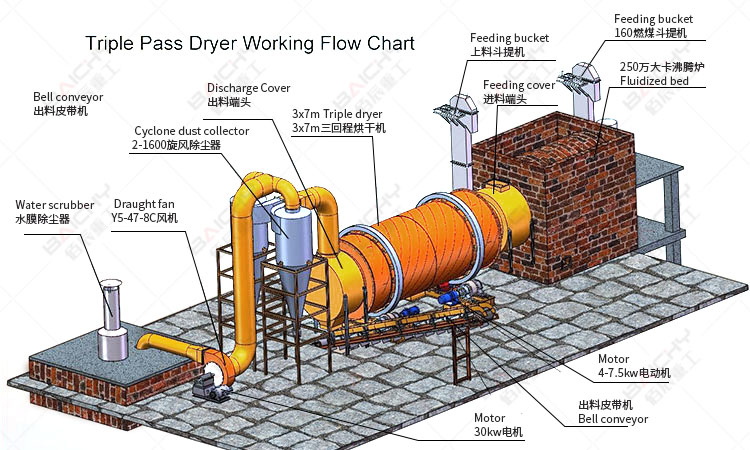

The working principle of the three-drum dryer is mainly based on the two drying methods of co-current and counter-current, and the material is fully dried through the heat exchange of multiple drums. The specific process is as follows:

| Model | Diameter of outer cylinder(m) | Length of outer cylinder (m) | Drum volume(m³) | Rotation speed(r/min) | Max. air flow temperature(℃) | Production capacity(t/h) | Power(kw) |

| Ф2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5x2 |

| Ф2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5x2 |

| Ф2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5x2 |

| Ф2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11x2 |

| Ф3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5x4 |

| Ф3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5x4 |

| Ф3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11x4 |

| Ф3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5x4 |

| Ф4.0*10m | 4 | 10 | 125.60 | 4-10 | 700-750 | 70-100 | 22x4 |

✔ Energy saving of 30%~50% (heat utilization rate of more than 80%)

✔ Small footprint (compact structure, 60% shorter length)

✔ More uniform drying (three-pass circulation to avoid caking or over-drying)

✔ Strong adaptability (can handle high-humidity, sticky, granular materials)

Depending on the model, the processing capacity ranges from a few tons to hundreds of tons per hour, depending on the initial moisture content of the material, the efficiency of the heat source, and the equipment specifications.

You can choose coal, gas, fuel oil, biomass, steam, electricity, or waste heat recovery. Choose the appropriate heat source according to environmental protection requirements and costs.

By adjusting parameters such as hot air temperature, drum speed, and feed speed, the moisture content of the finished product can usually be controlled below 1%.

It can be equipped with a cyclone dust collector, bag dust collector, or wet dust removal system to meet environmental emission standards and reduce dust pollution.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery