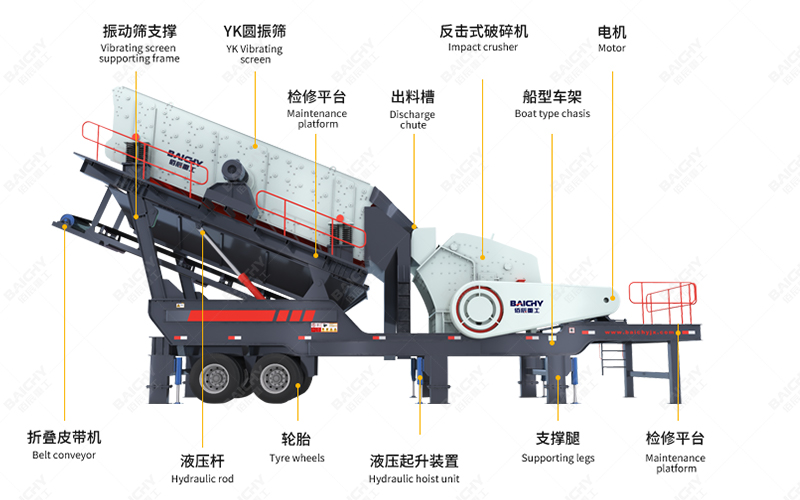

Modular crushing equipment that integrates an impact crusher, feeding system, screening module, and mobile chassis (tire/track), which can be flexibly transferred by traction or self-drive to achieve on-site medium and fine crushing of materials.

Key features:

• Crushing principle: The material is crushed by the impact collision between the high-speed rotating rotor and the impact plate (dynamic crushing force).

• Mobility: No fixed foundation is required, and it can be put into production within 1 hour.

• Modular design: Optional pre-screening, iron remover, dust removal device, etc.

Applicable stone type selection

• Medium and low hardness stone: Mohs hardness ≤ 6, typical materials include limestone, dolomite, coal gangue, etc.

Reason: high impact crushing efficiency, controllable hammer wear

• Building recycled materials: typical materials, concrete, bricks, asphalt blocks, etc.

Reason: three-dimensional particle shape after multi-stage crushing, suitable for recycled aggregate

• Medium hardness abrasive weak stone: Mohs hardness 6-7, typical material granite (need to reduce feed size)

Reason: a wear-resistant hammer is required, and the economy is better than cone crusher.

Not recommended scenario:

• Ultra-high hardness stone (basalt, quartzite>7)-the hammer wears too fast; it is recommended to use a mobile cone crusher instead.

• Viscous/high humidity materials- easy to block the counterattack chamber.

+86-15093222637

+86-15093222637