The integrated sand washing and dewatering equipment combines sand washing, recycling, dewatering, and wastewater treatment functions, providing users with comprehensive value upgrades through simplified investment, improved efficiency, and green production.

The sand washing and dewatering integrated equipment is an innovative solution specifically designed to address these industry pain points. It highly integrates efficient sand washing, fine sand recovery, mud-water separation, and dewatering functions into a single piece of equipment, achieving a "one-stop" processing solution from muddy, wet raw materials to clean, low-moisture finished sand, greatly simplifying the process and improving overall efficiency.

One piece of equipment integrates multiple processes, eliminating the need for multiple machines, saving on equipment, infrastructure, and land costs, especially suitable for projects with limited land availability.

Using cyclone separation technology, it recovers fine sand lost in traditional processes, increasing sand output by 10%-25%, optimizing grading, and directly increasing revenue.

Equipped with a high-efficiency water treatment system, it achieves wastewater recycling, saving over 80% of water, and the low-moisture filter cake is easy to dispose of, meeting environmental requirements.

The finished sand is clean, with low mud content (<3%) and low moisture content (10%-15%), meeting the high-end requirements of high-grade concrete and dry-mix mortar.

Fine sand recycling machine

manufactured sand production line

sand and gravel dewatering screen

sand washing and recycling integrated machine

A large-scale granite sand production line in Southeast Asia, whose original process involved direct use of a wheel-type sand washer after vibrating screening, suffered from serious fine sand loss, high powder content in the finished sand, and significant wastewater treatment pressure.

Solution: We customized an FC-15 integrated sand washing, dewatering, and recovery machine for them, replacing the original end-of-line sand washing equipment.

1. Output and recovery: The hourly processing capacity reached 150 tons, and the fine sand (0.16-0.6mm) recovery rate reached over 90%, increasing the overall sand output rate by approximately 18%.

2. Product Quality: The finished sand has a stable clay content of less than 2.5%, a moisture content reduced to 12%, and a controllable fineness modulus, making it highly favored by downstream ready-mix concrete plants.

3. Environmental Benefits: Equipped with a small filter press, the system achieves over 95% recycling of wash water, resulting in virtually zero wastewater discharge and successfully passing environmental inspections.

The sand washing and dewatering integrated equipment is widely used in fields such as manufactured sand production, natural sand purification, tailings recovery, and recycled aggregate processing from construction waste. It is a core piece of equipment for improving sand and gravel quality, achieving efficient resource utilization, and promoting environmentally friendly production.

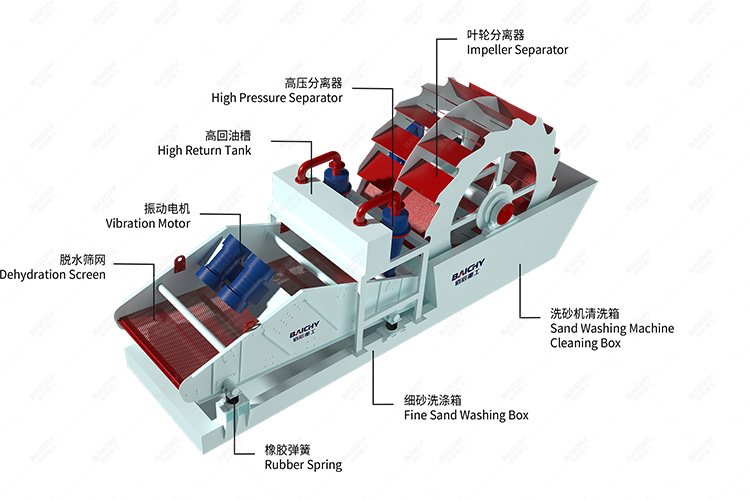

The working principle of the integrated sand washing and dewatering equipment is to achieve efficient separation and recovery of sand, water, and mud through a three-step process: classification washing, hydraulic cyclone concentration, and mechanical dewatering.

1. Classification Washing: The raw materials enter the washing tank, where they are tumbled and rubbed under the action of the impeller, removing surface impurities, and the mud powder is carried away by the water flow.

2. Fine Sand Recovery: The muddy water containing fine sand enters the cyclone separator, where preliminary separation of sand, water, and mud is achieved under centrifugal force. The fine sand is then recovered after secondary dewatering by a dewatering screen.

3. Muddy Water Treatment: The separated turbid water enters a sedimentation tank or a matching filter press equipment. The clean water is recycled, and the mud is pressed into low-moisture mud cakes, achieving zero discharge.

This process integrates mechanical cleaning, centrifugal separation, and screening dewatering in a single piece of equipment, simultaneously completing "washing, recovery, dewatering, and water recycling," balancing efficiency and environmental protection.

| Model |

Impeller Diameter (mm) |

Impeller Width (mm) |

Motor power |

Screen mesh size |

Motor power |

Cyclone Separtor Spec |

Sand Output (t/h) |

Total Power (kw) |

Overall size(mm) |

| 2610+1225 | 2450 | 1000 | 7.5 | 60 mesh | 2*2.2KW | 300 | 30-80 | 26.9 | 6830*2170*2550 |

| 2915+1530 | 2560 | 1500 | 11 | 60 mesh | 2*3KW | 300x2 | 60-120 | 35.5 | 7000*3050*2900 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery