Single-drum dryer is a device that dries materials by exchanging heat with high-temperature hot air through the rotation of the drum. Single-drum dryer, also known as rotary drum dryer and single-drum horizontal dryer, is a highly efficient drying equipment that is widely used in many fields such as mineral processing, building materials, metallurgy, chemical industry, food, agriculture, etc.

• Large capacity design: The single-drum structure is simple, and the internal space utilization rate is high. It can process many high-humidity ores (such as coal powder, iron ore concentrate, tailings, etc.). The processing capacity of a single machine can reach tens to hundreds of tons per hour.

• Thermal efficiency optimization: Adopt a countercurrent or parallel current heating method, and use the internal lifting plate device to make the material fully contact the hot air, increase the thermal energy utilization rate by 20%~30%, and reduce fuel consumption.

• Rapid drying: High-temperature airflow (up to 700℃ or more) directly exchanges heat with the material, and the water evaporates quickly, which is especially suitable for high-moisture ores (such as clay, sludge, etc.).

Cement drying

Gypsum powder drying

Tailings drying

Slag drying

Due to its many advantages, single-drum dryers have been widely used in industrial production. For example, in the building materials industry, it is used to dry materials such as slag, river sand, and clay; in the metallurgical industry, it is used to dry materials such as leaching slag from metal processing; in the chemical industry, it is used to dry non-heat-sensitive materials; in the food industry, it is used to dry agricultural products such as grains and dried fruits.

• Wide material compatibility: By adjusting parameters such as speed, inclination, temperature, etc., it can process minerals of different particle sizes (powder to block) and humidity (10%~40%), such as quartz sand, copper concentrate, phosphogypsum, etc.

• Strong environmental adaptability: No complex pretreatment is required, and impurities or sticky materials can be dried directly; some models can integrate dust removal and desulfurization devices to meet environmental emission requirements.

• Process adaptability: It can form a production line with crushing, ball milling, mineral processing, and other equipment, and supports customized design (such as extended cylinder, special sealing structure) to adapt to specific mineral characteristics.

The movement of the material is due to the combined effect of inclination of the shell to the horizontal and the internal tumbling action or mechanical turn over thus the name tumbling dryer.

The cylinder body of the dryer is made of steel material, which has the characteristics of high hardness and high toughness; and compared with other materials, its wear resistance is higher.

Due to the high air velocity, the material is well dispersed in the gas phase, and the entire surface of the material can be used as the effective drying area, so the limited drying area is greatly increased.

The dryer system has good sealing performance and is equipped with a complete dust removal device so that the dust is small and the operating environment is good.

The new internal structure strengthens the cleaning and heat conduction of the dispersed materials.

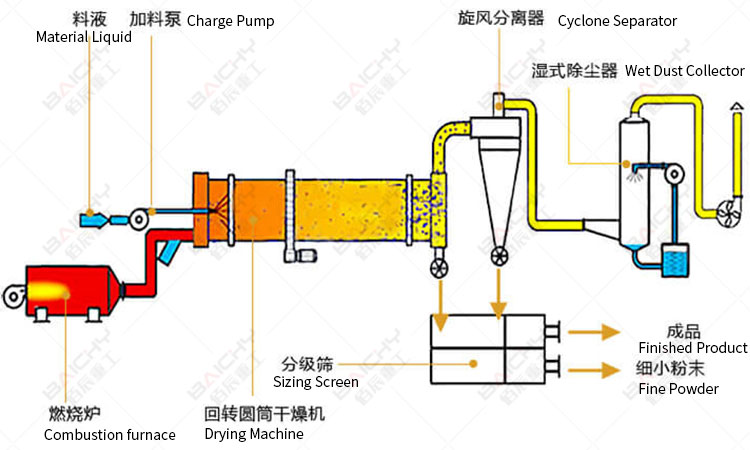

1. Heat conduction: The single-drum dryer is usually equipped with a heat source system, such as a hot air furnace or a burner, to generate high-temperature hot air flow. The hot air flow enters the drum through the hot air duct of the dryer and comes into direct contact with the wet material. The moisture in the wet material evaporates rapidly at high temperature and is carried away by the hot air flow, thereby achieving the drying of the material.

2. Material tumbling: The drum of the single-drum dryer rotates under the drive of the motor. There is a lifting plate or other stirring device inside the drum. When the drum rotates, these devices will continuously turn up and scatter the material, so that the material is continuously tumbled and mixed in the drum. This tumbling and mixing helps the material to fully contact with the hot air flow and improve the drying efficiency. At the same time, tumbling can also prevent the material from forming accumulation and agglomeration in the drum, ensuring that the material is evenly heated.

3. Material conveying: During the rotation of the drum, the material will be affected by a certain gravity and the inclination angle of the drum, and thus move along the drum to the discharge end. This continuous material conveying process ensures the residence time of the material in the drum, so that the material is fully dried.

| Spec. (Dia.x Length mm) |

Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air Temperature(℃) |

Rotate Speed(r/min) | Main Motor(kw) |

| Φ600x6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800x8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800x10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000x10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000x12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200x8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800x12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000x18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000x20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400x16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400x18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400x20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600x24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600x28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000x20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 85 |

| Φ3000x25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3200x25000 | 201 | 42.9-53.6 | 3~5 | 700~800 | 1.5~5 | 110 |

• Ore: iron ore concentrate, copper ore, gold ore, quartz sand, etc.

• Coal: washed coal, coal slime (water content ≤30%).

• Building materials: clay, limestone, gypsum, etc.

• Others: some industrial waste residues (such as tailings, slag).

Inapplicable scenarios: materials with high viscosity (such as sludge), heat-sensitive materials (easy to decompose or burn).

• Small: 5~20 tons/hour (suitable for laboratories or small-scale production).

• Medium: 20~100 tons/hour (common in small and medium-sized mines).

• Large: 100~500 tons/hour (for large-scale ore dressing plants).

• Heat source: coal (most common), gas, oil, or electric heating.

• Thermal efficiency: about 50%~60%, lower than a three-drum dryer, but lower equipment cost.

• Power consumption: about 5~15 kWh/ton (depending on material moisture and system design).

• Daily maintenance: check bearing lubrication, transmission gear wear, and lifting plate fixation.

• Weekly maintenance: clean the residual material in the drum to prevent agglomeration.

• Monthly maintenance: check whether the refractory lining and hot air duct are damaged.

• Annual overhaul: replace the severely worn support wheels, gears, and seals.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery