The spiral sand washing machine has significant advantages in efficient cleaning, reasonable structure, simple operation, wear resistance and durability, strong adaptability, energy saving, environmental protection and easy maintenance. It is an efficient, stable and reliable sand and gravel processing equipment.

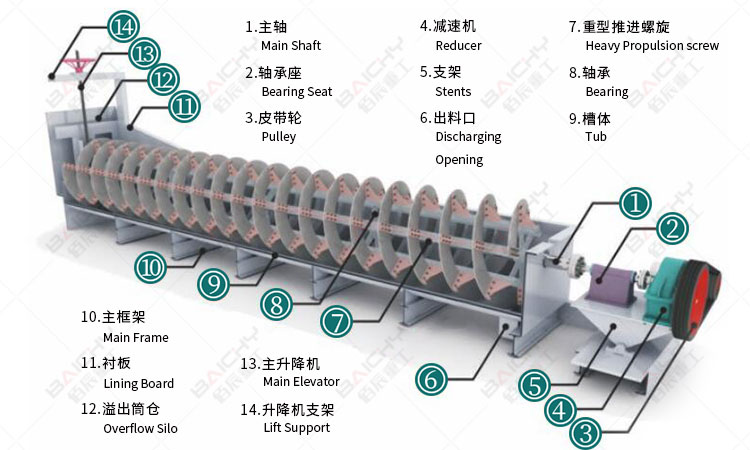

Spiral sand washing machine is a kind of sand washing machine. It mainly stirs the sand and gravel through the spiral device in the equipment, so that the soil in the sand and gravel is mixed with water and discharged from the flow port on the equipment.

The sand and gravel are screened under the action of the spiral device and discharged from the discharge port at the top, thereby realizing the cleaning of the sand and gravel.

screw sand washing, sand screw plants, spiral sand washing

screw sand washing, sand screw plants, spiral sand washing

screw sand washing, sand screw plants, spiral sand washing

screw sand washing, sand screw plants, spiral sand washing

Spiral sand washing machine is used to process construction sand, such as sand and gravel aggregate cleaning in a concrete mixing station. Through cleaning, dirt, stone powder and other impurities on the surface of sand and gravel can be removed, and the cleanliness and quality of sand and gravel can be improved, thereby ensuring the quality of concrete.

Spiral sand washing machine is suitable for processing sand and gravel of various particle sizes and hardness, including natural sand, machine-made sand, etc. At the same time, the equipment can also be customized according to the actual needs of users to meet the needs of different industries and application scenarios.

The spiral sand washing machine is driven by a motor, and the impeller rotates slowly through the transmission of components such as a V-belt and a reducer. The material (such as sand, stone, ore, etc.) enters the washing tank from the feed tank and is rolled and stirred under the drive of the impeller to remove impurities covering the surface of the material.

| Model | Spirals Number (pcs) |

Screw Diameter (mm) |

Sink Length (mm) |

Capacity (t/h) |

Motor Power (kw) |

| XL920-7.5 | 1 | ∅920 | 3600 | 40-60 | 4P-11 |

| 2XL920-7.5 | 2 | ∅920 | 7500 | 90-120 | 4P-11x2 |

| XL1120-7.5 | 1 | ∅1120 | 5000 | 40-120 | 4P-18.5 |

| 2XL1120-7.5 | 2 | ∅1120 | 10000 | 80-240 | 4P-18.5x2 |

| XL1500-9 | 1 | ∅1500 | 9800 | 100-170 | 4P-22 |

| 2XL1500-9 | 2 | ∅1500 | 18000 | 200-280 | 4P-22x2 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery