The crushing ratio is an important evaluation index of jaw crusher, which is generally 3-6. The particle size of the material after crushing is relatively uniform. The equipment is energy-saving, with a single machine saving 15%-30% of electricity and a system saving more than doubled. It can meet the requirements of different users.

In mining, construction, metallurgy and other industries, jaw crusher is one of the most commonly used coarse crushing equipment. It has become the first choice of many companies with its advantages such as simple structure, large crushing ratio and convenient maintenance.

Baichy Heavy Industry comprehensively analyzes the working principle, model classification, application scenarios, purchase suggestions and maintenance tips of jaw crusher to help you choose the most suitable crushing equipment!

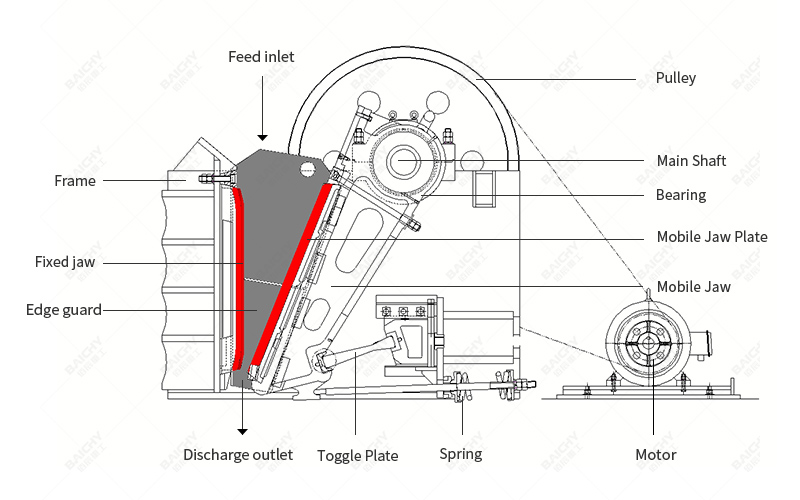

Jaw crusher is a device that uses two jaw plates (a moving jaw and a fixed jaw) to squeeze and crush materials. It is suitable for coarse and medium crushing of various ores and rocks with compressive strength ≤320MPa.

• High crushing ratio (usually up to 4-6, some models can reach 10)

• Simple structure, low maintenance cost

• Strong adaptability (can handle wet and sticky materials, not easy to clog)

• Low energy consumption, stable operation

Kyrgyzstan Customer Site

PE600x900 Jaw Crusher

Zimbabwe Customer Site

PE600x900 Jaw Crusher

• Small production line (<100t/h): PE-250x400, PE-400×600, PE-500×750

• Medium production line (100-300t/h): PE-600×900, PE-750×1060

• Large production line (>300t/h): PE-900×1200, C series jaw crusher (such as C160)

1. Fixed production line: jaw crusher + cone crusher/impact crusher + vibrating screen

2. Mobile crushing station: tire/crawler mobile jaw crusher unit

1. Mexico Iron Ore Project: Using PE-600×900 jaw crusher, the processing capacity reaches 120t/h, and the crushing ratio reaches 6:1.

2. Brazil Quarry: Using a mobile jaw crusher unit to achieve on-site crushing, reducing transportation costs by 40%.

Jaw crusher is used as the primary crushing process for metal ores such as gold, iron, and copper, as well as non-metallic ores such as limestone and granite. It crushes large pieces of raw ore into medium particle size (usually 100-350mm) for subsequent fine crushing or grinding.

High-strength frame (integral/combined), movable & fixed jaw with high-Mn steel plates, eccentric shaft with flywheel, adjustable discharge (wedge/hydraulic), and V-belt motor drive. Ensures efficient, stable crushing.

• The material enters the crushing chamber from the top feed port and accumulates between the movable jaw and the fixed jaw.

• The motor drives the eccentric shaft to rotate, driving the movable jaw to approach the fixed jaw.

• The material is crushed under the action of extrusion, and the material that meets the particle size requirement is discharged from the bottom.

• The eccentric shaft continues to rotate, and the movable jaw moves away from the fixed jaw to prepare for the next round of crushing.

• The flywheel releases the stored energy to maintain stable operation.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PE250x400 | 250x400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

| PE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery