When processing medium- and coarse-grained, large-volume materials, it provides the most efficient, stable, and environmentally friendly screening solution with minimal energy consumption and maintenance costs.

If your production process involves high-volume, high-efficiency screening of medium- and coarse-grained materials (ranging from a few millimeters to tens of millimeters), linear screens are almost always the preferred solution.

1. Grading: This is the most common application, accounting for approximately 80%. It involves separating a mixed material into two or more different particle size products based on particle size. For example, crushed stone is sorted into different sizes in a sand and gravel plant.

2. Dewatering: Using vibration and the screen surface, liquid (usually water) is removed from slurry materials, achieving solid-liquid separation and producing a solid product with a lower moisture content. An example is the dewatering of coal sludge in a coal washing plant.

3. Media Recovery: Mainly used in the heavy media separation process, it separates the material from the heavy media (such as magnetite powder) and recovers the media for recycling.

4. Impurity Removal: It removes small amounts of oversized or undersized particles from the material, or removes impurities, to produce a pure, uniformly sized product. An example is the removal of plastic pellets.

The advantages of linear screens can be summarized as follows: When processing medium- and coarse-grained, large-volume materials, they provide the most efficient, stable, and environmentally friendly screening solution with minimal energy consumption and maintenance costs. This is the fundamental reason why they are so popular in industries such as mining, building materials, and chemicals.

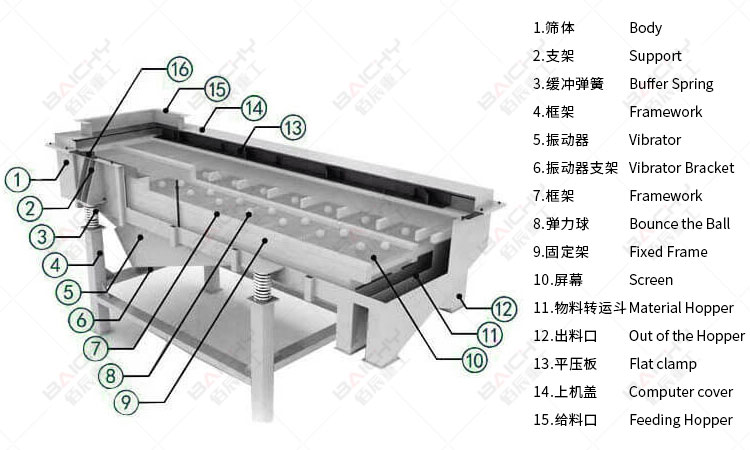

1. High Efficiency and High Processing Capacity: The screen surface of a linear screen is typically installed horizontally or at a slight angle. The material jumps across the screen surface rapidly and moves forward in a straight line, resulting in a long running path and very high processing speeds. 2. High screening accuracy and multi-level grading: Utilizes a multi-layer screen design (typically 2-5 layers).

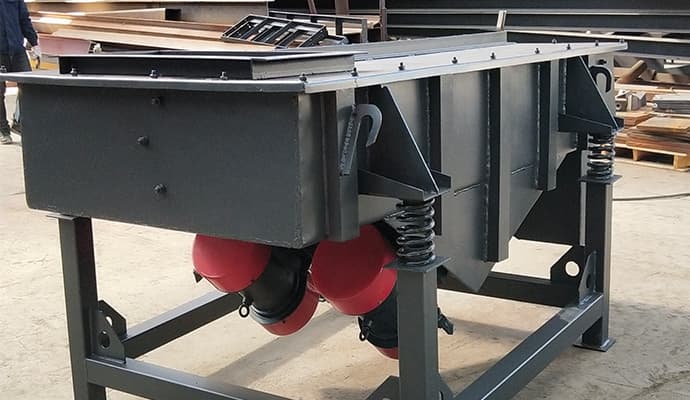

3. Simple structure, stable and reliable operation: The power source comes from a vibrating motor, eliminating the complex gears, belts, and other transmission mechanisms found in traditional eccentric shaft vibrators.

4. Low energy consumption and low maintenance costs: By eliminating complex transmission components, energy loss is minimized, and the vibrating motor itself is highly efficient.

5. Enclosed design, environmentally friendly and dust-free: The screen box can be easily fully enclosed, and flexible connectors can be installed at both the inlet and outlet.

6. Flexible design, easy customization: Many parameters of the linear screen can be adjusted to meet customer needs.

7. Long service life: The solid box structure, high-quality screen material, and reliable vibrating motor together ensure the long life of the equipment.

Due to its high throughput, efficient grading, and robust construction, linear screens are essential core screening equipment in many industrial sectors.

The linear screen operates on a simple yet efficient principle. Two vibration motors rotate synchronously in opposite directions, generating a combined force that drives the screen box in a straight, directional vibration.

This motion causes material on the screen surface to be continuously thrown upward and forward in a parabolic trajectory.

• Fine particles pass through the screen mesh and are collected as undersize.

• Larger particles continue moving forward and are discharged as oversize.

• In multi-layer designs, material is sequentially screened across different mesh sizes, allowing for simultaneous classification into multiple particle grades.

The screen’s vibration angle—typically between 30° and 60°—ensures optimal material dispersion and forwarding efficiency.

| Model | Screen size(mm) | Particle size (mm) | Screen slope | Double amplitude(mm) (°) | Layer | Frequency(r/min) | Power(kw) |

| SZF-520 | 500X2000 | 0.074-60 | 1°-7° | 3-4.5 | 1-6 | 960 | 2x(0.37-0.75) |

| ZX-525 | 500X2500 | 2x(0.37-0.75) | |||||

| ZX-1020 | 1000X2000 | 2x(0.55-1.0) | |||||

| ZX-1025 | 1000X2500 | 2x(0.55-1.0) | |||||

| SZF-1225 | 1200x2500 | 2x(0.75-1.5) | |||||

| SZF-1230 | 1200x3000 | 2x(0.75-1.5) | |||||

| SZF-1235 | 1200x3500 | 2x(1.5-2.0) | |||||

| SZF-1530 | 1500x3000 | 2x(2.0-2.2) | |||||

| SZF-1535 | 1500x3500 | 2x(2.0-2.2) |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery