![]()

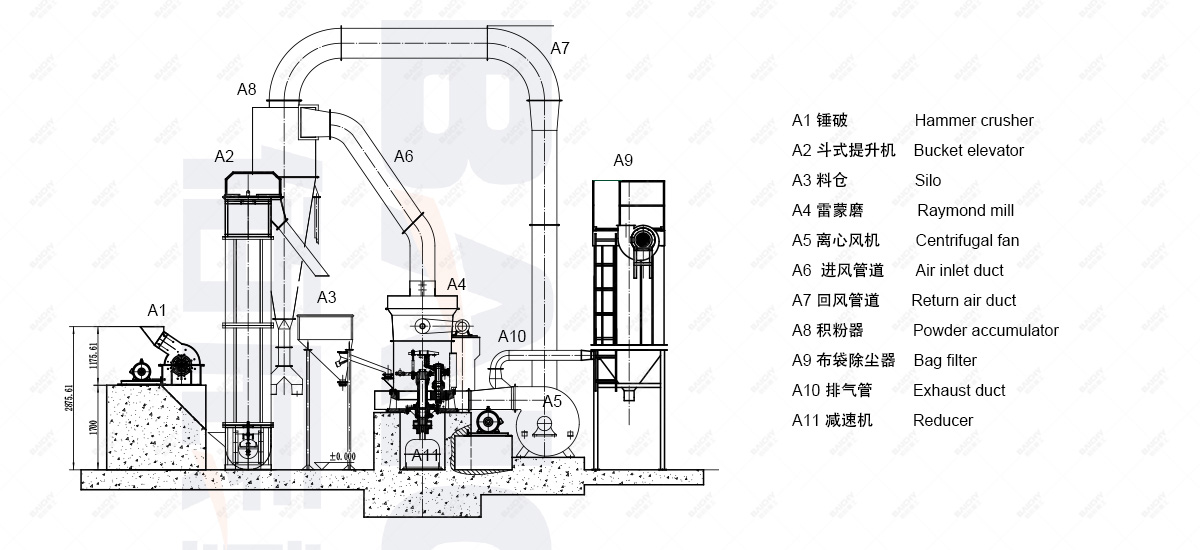

The barite grinding production line processes raw barite ore into fine barite powder through a series of technological processes. It has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements.

The barite grinding production line has a simple configuration and relatively low investment cost.

The whole set of equipment has good performance and stable operation. It is highly targeted at grinding barite and has a large processing capacity. The output can be increased by more than 50%.

Effectively reduce operating costs and improve user processing plant efficiency.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery