Small jaw crusher jaws are adjustable down to about half an inch, and up to about two and a half to three inches of discharge. The final products can be directly put into the application without further crushing by other crushers.

• Large jaw crusher: usually fixed installation, suitable for large-scale production lines, but the relocation cost is high.

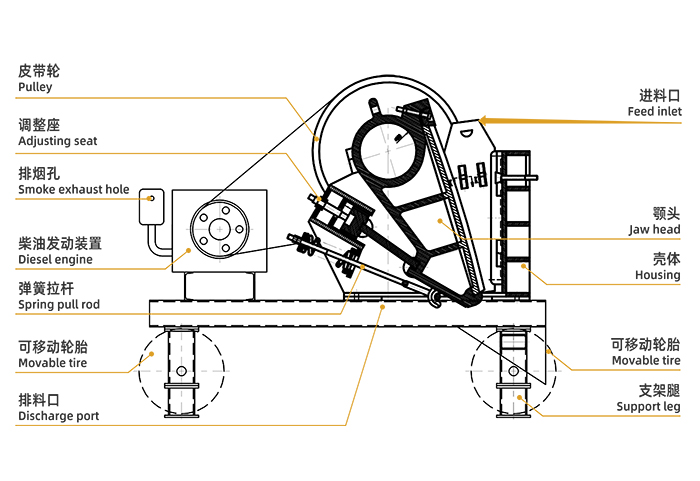

• Small jaw crusher: can be equipped with a mobile chassis (such as tire or crawler), easy to transfer, especially suitable for temporary construction sites, construction waste recycling, small quarries and other scenes.

• A standard large jaw crusher (such as PE600×900) usually costs hundreds of thousands or even millions, while a small jaw crusher (such as PE250×400) only costs tens of thousands of yuan, which is more suitable for small and medium-sized enterprises or individual investors with limited budgets.

• Lower maintenance costs and more convenient replacement of accessories.

• The motor power of small jaw crushers is usually between 5.5-30kW, which is more energy-saving than large equipment and conforms to the current policy trend of green mining and low-carbon production.

• Some new small jaw crushers adopt noise reduction design to reduce the impact on the surrounding environment.

Small jaw crusher price

jaw crusher model

PE250x400 jaw crusher

small stone crusher manufacturer

• PE150×250 (smallest model): feed opening 150×250mm, maximum feed 125mm, suitable for laboratory or small sand and gravel processing.

• PE250×400 (medium-sized): feed opening 250×400mm, maximum feed 210mm, suitable for small and medium-sized quarries.

• Discharge is controlled by adjusting the jaw plate spacing, generally between 10-100mm, which can meet different crushing needs.

• If used for construction waste recycling or small quarrying, PE250×400 is recommended.

• If higher capacity is required, consider a mobile small jaw crusher, such as a tire-type jaw crusher.

The small jaw crusher is used extensively throughout the aggregate and mineral processing industry. Also, it is applied in mining, aggregate production, construction material recycling, etc. It is one of the most common limestone stone crushers.

1. Recycling of construction waste

Small jaw crusher can easily crush concrete blocks, bricks and tiles, etc., and produce recycled aggregates with screening equipment to reduce the cost of construction waste treatment.

2. Primary crushing of small gold mines/tungsten mines

In Africa, Southeast Asia and other regions, small miners often use diesel-driven small jaw crushers for primary crushing of ore, which is low-cost and quick to see results.

3. Mobile crushing-ideal choice for temporary projects

With tire or crawler chassis, it can be quickly deployed in scenes such as highway construction, post-disaster reconstruction, and temporary quarries.

| Model | Feeding Open Size (mm) | Max. Feed Size (mm) |

Outlet adjusting size(mm) |

Capacity(t/h) |

Motor power(kw) |

Overall dimension(mm) |

| PE150X250 | 150X250 | 130 | 15-45 | 1-4 | 5.5 | 896*745*935 |

| PE200X300 | 200X300 | 180 | 15-50 | 2-6 | 5.5 | 910*750*990 |

| PE200X350 | 200X350 | 180 | 18-70 | 3-10 | 7.5 | 1000*870*990 |

| PE250X400 | 250X400 | 210 | 25-60 | 5-20 | 15 | 1215*1520*1030 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery