The electromagnetic feeder is specially designed for evenly conveying bulk materials before the coarse crusher in crushing and screening. It is mainly used to continuously and evenly feed the crushing machinery in the sand and gravel production line, and to coarsely screen the materials.

An electromagnetic vibrating feeder is widely used in crushing and screening combined equipment of limestone, granite, gabbro, basalt, river rock, coal, gangue, quartz, diabase, iron ore, copper ore, zinc ore, manganese ore.

The electromagnetic vibrating feeder has reliable operation, low noise, low energy consumption, no flushing phenomenon, long service life, convenient maintenance, lightweight, small size, convenient equipment adjustment and installation, and good comprehensive performance.

The equipment is easy to install and maintain and has low operating costs.

The equipment is stable and reliable in operation, low in noise, long in life, and stable in vibration shape.

The amplitude is stable, the operation is reliable, and the adaptability to various materials is strong.

Small size, lightweight, simple structure; uniform feeding, easy operation.

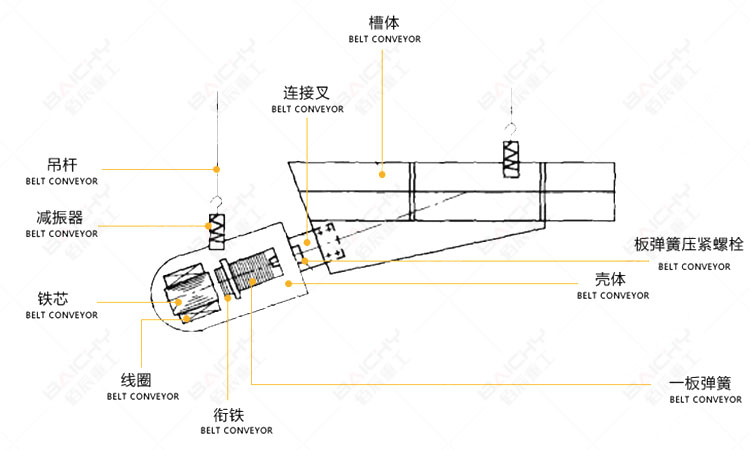

The vibrating feeder uses the rotation of the eccentric block in the vibrator to generate centrifugal force so that the movable parts such as the screen box and the vibrator perform forced continuous circular or approximate circular motion.

The vibrating feeder is composed of a feeding trough, a vibrator, a spring support, and a transmission device. The vibration source of the trough vibratory feeding is the exciter, which is composed of two eccentric shafts (active and passive) and a gear pair. The motor drives the active shaft through the V-belt, and then the gear on the active shaft meshes with the passive shaft. When rotating, the active and passive shafts rotate in opposite directions at the same time, which makes the tank body vibrate, so that the material flows continuously and achieves the purpose of conveying materials.

| Model | Feeding capacity(tph) | Max input size(mm) | Power(kw) | Valtage(v) | Current(a) | Double swing(mm) |

| GZ1 | 5 | 50 | 0.06 | 220 | <=1 | 1.75 |

| GZ2 | 10 | 60 | 0.15 | 220 | <=2.3 | 17.5 |

| GZ3 | 25 | 70 | 0.2 | 220 | <=3.8 | 1.75 |

| GZ4 | 50 | 100 | 0.45 | 220 | <=7 | 1.75 |

| GZ5 | 100 | 150 | 0.65 | 220 | <=7 | 1.75 |

https://www.baichychina.com/Powder/electromagnetic.html

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery