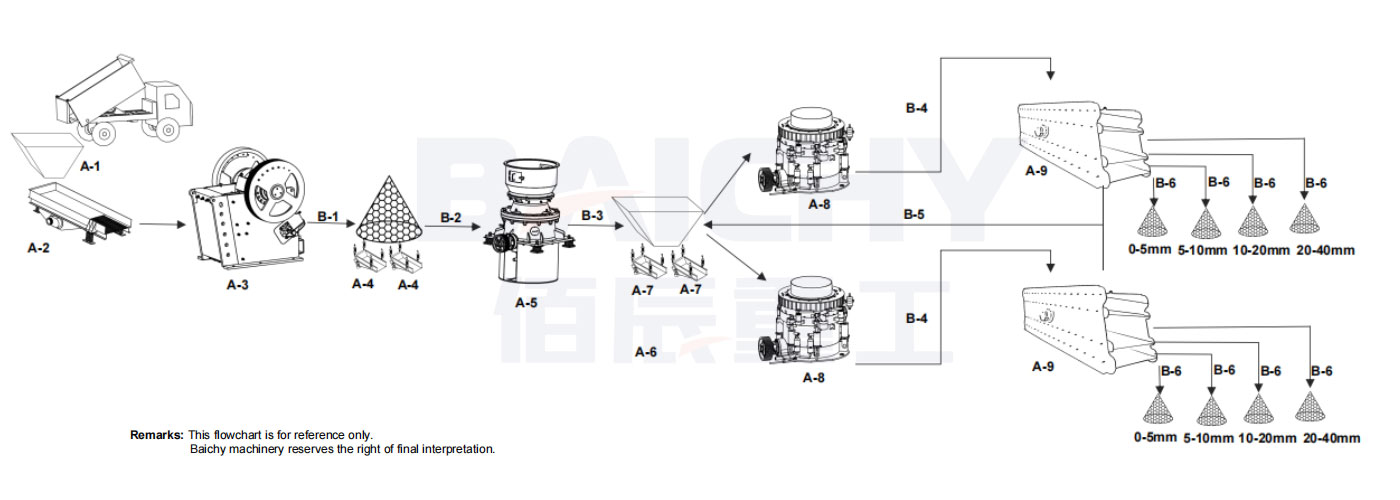

This stone crushing plant is specially designed to produce medium and large-sized sand and gravel aggregates. The core processing capacity is up to 500 t/h. It is suitable for hard stones such as granite and basalt. The finished product is adjustable (0-5mm machine-made sand to 20-40mm aggregates).

|

Equipment |

Vibrating feeder ZSW1300X4900 | PE Jaw Crusher1000X1200 or C140 Jaw Crusher | Cone Crusher DG500 | Cone Crusher HP300 | 4YK2470 Vibrating Screen | Belt Conveyor |

|

Raw materials |

500 t/h stone crushing station can efficiently crush granite, limestone, basalt, pebbles and other hard rocks and construction waste, suitable for sand and gravel aggregates, mining and solid waste recycling. |

|

Feed Size |

0-800mm |

|

Capacity |

500t/h |

|

Finished product |

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

|

Design requirements

|

1. What material will be crushed? 2. What is the required production capacity? 3. What are the required specifications for the finished product? |

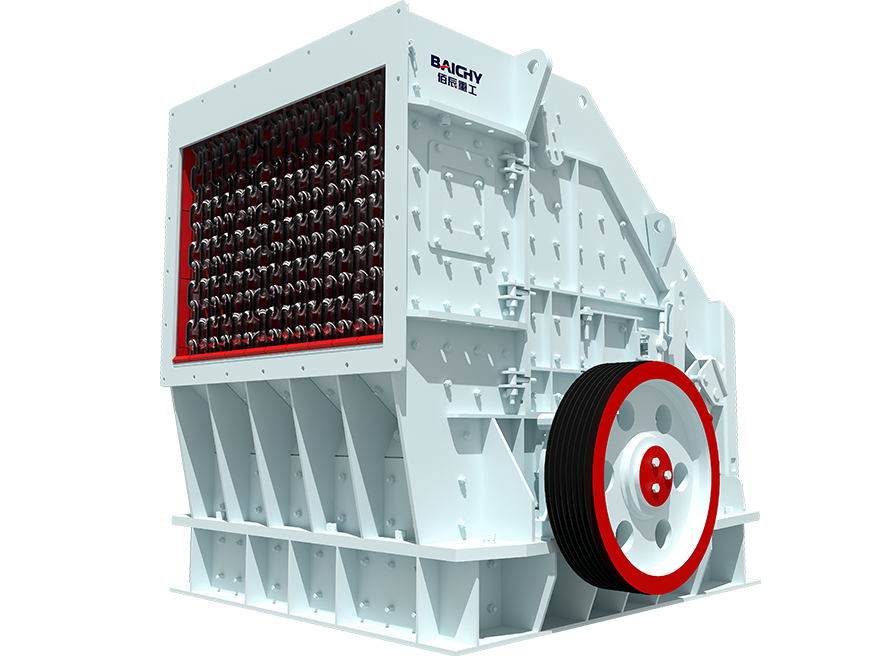

The CI series impact crusher is a highly efficient and energy-saving crushing equipment designed specifically for sand production and material shaping. It features a large feed size, high crushing efficiency, excellent product particle shape, and long service life of wear parts. It is widely used in various fields such as ore crushing, manufactured sand production, and construction aggregate processing.

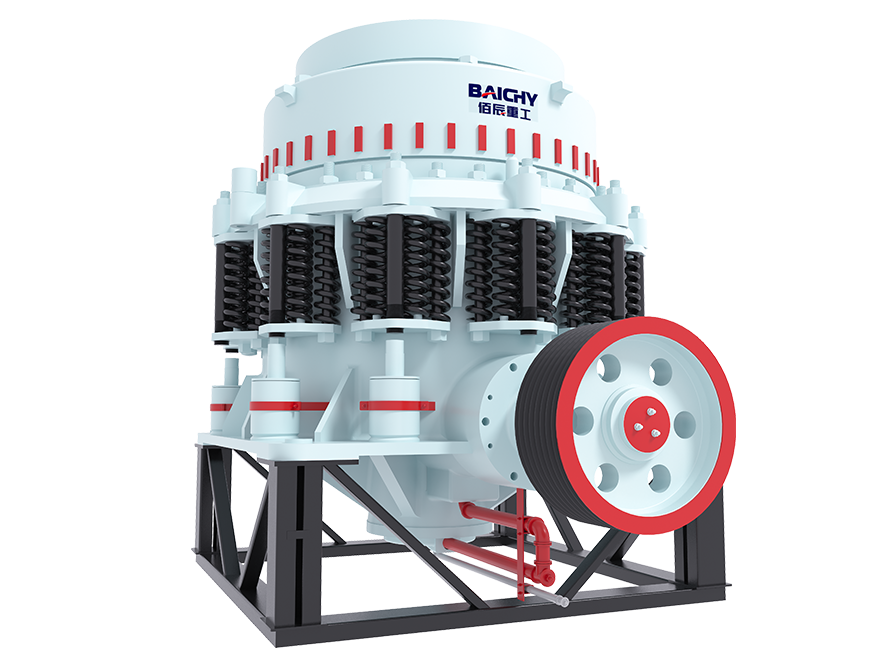

CS Symons cone crusher is a high-performance cone crusher. It is a modern high-performance crusher designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

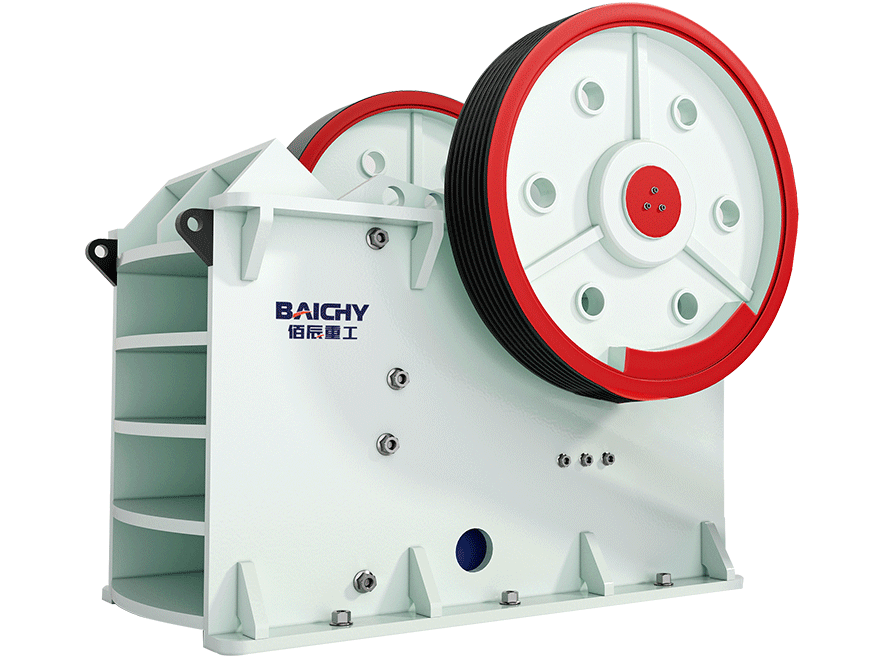

Solve your primary crushing problems in one go!

Baichy Heavy Industry's jaw crusher is specifically designed for crushing hard materials such as granite, basalt, and iron ore. We understand that stable primary crushing is the cornerstone of the entire production line.

crushing and screening plant

crush finished product display

cone crusher

In mining, construction aggregate production, highway and railway construction, and other fields, the 500 t/h stationary stone crushing line has become the preferred solution for large-scale sand and gravel processing projects due to its high production capacity, stable operation, and low maintenance costs.

• High and stable output: With an output of 500 t/h, it meets the efficient production needs of large-scale sand and gravel plants and quarries.

• Modular design: The fixed structure allows for a compact equipment layout and adapts to perse site conditions.

• Low operating costs: Utilizes high-efficiency crushers (such as a jaw crusher + cone crusher combination) with low energy consumption and minimal wear.

• Intelligent control: The PLC automation system monitors production data in real time, reducing manual intervention.

• High adaptability: It can crush a variety of hard rocks, including granite, basalt, and limestone, with adjustable finished product particle size.

The 500 t/h stationary stone crushing line is an efficient solution for large-scale sand and gravel aggregate processing and mining crushing. We provide one-stop service from design and installation to after-sales service, ensuring your project runs efficiently and stably!

Further reading: Granite Crushing Production Line Configuration Guide: From Selection To Installation | Equipment Selection Guide For Sand And Gravel Aggregate Production Line

A: The recommended site length is ≥ 80 meters and the width is ≥ 50 meters, depending on the equipment layout.

A: By adjusting the cone crusher discharge opening, we can produce various sizes, including 0-5mm, 5-10mm, and 10-20mm.

A: Generally, it takes 30-45 days (including foundation construction), depending on the project scale.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.