Widely used in sand, mining, coal, building materials, chemicals, energy, metallurgy, recycling, agriculture, and grain processing. Ideal for screening moist, sticky, or small-to-medium-sized materials.

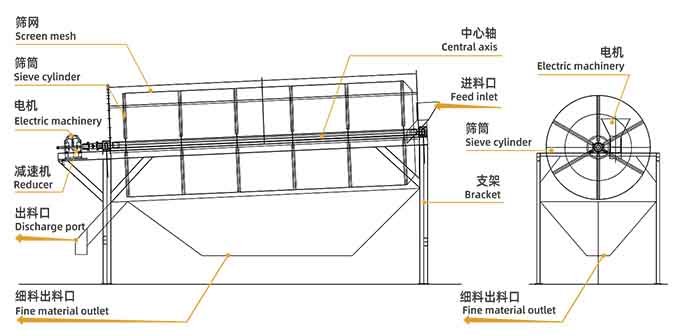

The trommel screen (also known as a rotary screen or rotary screening machine) is a traditional and efficient screening equipment. Its main body is a cylindrical screen drum installed at an inclined or horizontal angle, which rotates uniformly around its central axis driven by a motor. Material enters the drum from the feed inlet, and as the drum rotates, the material is continuously tumbled and scattered inside the screen drum. Material particles smaller than the screen mesh fall through the screen as undersize material, while larger particles gradually move forward along the screen surface and are finally discharged from the discharge end as oversize material, thus achieving the purpose of classifying materials according to particle size. This equipment has a robust structure, stable operation, and strong adaptability, making it an ideal choice for continuous screening operations in many industries.

1. Screen Drum: The core working component, composed of drive wheel hoops, support wheel hoops, wear-resistant screen plates (or screen mesh) and internal guide plates, which determine the classification particle size and processing capacity.

2. Transmission System: Includes explosion-proof motor, cycloidal pinwheel reducer, coupling and drive wheel, providing stable rotational power for the screen drum.

3. Support and Roller System: Consists of a heavy-duty frame, support rollers (rolling rings) and bearing seats that support the screen drum, ensuring stable rotation.

4. Feed Hopper and Discharge Chute: The feed hopper guides the material evenly into the screen drum; the discharge chute (usually multiple chutes, corresponding to different particle sizes) is used to collect and guide the screened material.

5. Sealed Dust Cover: (Optional) Prevents dust from escaping during the screening process, meeting environmental protection requirements. 6. Screen Cleaning Device: (Optional) Such as built-in rotating brushes, elastic cleaning balls, etc., used for automatically cleaning the screen holes to prevent clogging.

stone screening equipment

Rotary screen

Rotary screen mesh

Rotary screeners are being shipped

1. High screening efficiency and large processing capacity: The material continuously tumbles and slides inside the drum, making full contact with the screen surface, effectively preventing clogging. It is particularly suitable for processing materials with high moisture content and high viscosity, and has a large processing capacity per unit time.

2. Stable operation and low noise: The overall structure design is reasonable, the transmission device is simple and reliable, the equipment runs smoothly, with low vibration and low working noise, and can operate continuously for 24 hours.

3. Strong adaptability and wide range of applications: By replacing screen plates (screens) with different apertures, it can meet various particle size classification needs. It can be designed as multi-layered (usually 2-4 layers), simultaneously separating multiple products of different specifications. It is insensitive to the humidity and viscosity of the material and is suitable for harsh working conditions.

4. Robust structure and easy maintenance: The main frame is welded with heavy-duty steel, and the screen drum is composed of reinforced hoops and wear-resistant screen plates, making it sturdy, durable, and long-lasting. The equipment has a modular design, key components are easy to disassemble, and daily maintenance is simple and convenient.

Suitable for screening a variety of bulk materials, such as natural sand, crushed stone, river pebbles, mountain sand, quartz sand, coal, coke, ore, refractory materials, chemical raw materials, recycled aggregates, domestic waste, organic fertilizers, and grains.

The trommel screen utilizes the combined action of mechanical rotation and gravity to achieve efficient material screening. Its working process can be pided into the following four key steps:

1. Rotational Lifting: The motor drives the cylindrical screen drum to rotate at a constant speed through a gearbox. After entering from the feed inlet, the material is lifted upwards by the inner wall of the rotating screen drum.

2. Scattering and Screening: After being lifted to a certain height, the material falls in a waterfall-like manner under the action of gravity. Fine particles smaller than the screen holes pass through the holes and fall into the lower collection hopper, becoming the undersize material.

3. Conveying and Discharge: Coarse particles larger than the screen holes cannot pass through the screen. Under the continuous rotation of the screen drum and a slight inclination angle, they slide and roll along the screen surface to the discharge outlet, and are finally discharged from the other end, becoming the oversize material.

4. Motion Control: By adjusting the rotation speed and inclination angle of the screen drum, the screening efficiency and accuracy can be optimized. The rotation speed affects the scattering intensity of the material, and the inclination angle controls the residence time of the material in the drum; both factors jointly determine the final screening effect.

| Model | Screen Diameter(mm) | Screen Length(mm) | Mesh size(mm) | Max feeding size(mm) | Capacity(t/h) | Power(kw) |

| GTS0618 | 600 | 1800 | 2-80 | <300 | 0.5-2 | 1.1 |

| GTS0824 | 800 | 2400 | 2-80 | <300 | 2-20 | 2.2 |

| GTS1030 | 1000 | 3000 | 2-80 | <300 | 20-100 | 4 |

| GTS1236 | 1200 | 3600 | 2-80 | <300 | 30-120 | 7.5 |

| GTS1545 | 1500 | 4500 | 2-80 | <300 | 60-280 | 11 |

| GTS1860 | 1800 | 6000 | 2-80 | <300 | 80-350 | 22 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery