High-efficiency fine crusher, also known as fine crusher, new fine crusher, or third-generation sand-making machine, has reached the international leading level in performance and is the most effective, practical, and reliable stone crushing machine.

The fine crusher (also known as a fine crushing machine) is a new type of high-efficiency crushing equipment developed by our company. It adopts the impact crushing principle and is optimized for domestic mining conditions. This equipment features a large crushing ratio, low energy consumption, and stable operation. It can crush materials to a fine particle size of 0-10mm, making it an ideal device for artificial sand production and stone shaping.

1. High efficiency and energy saving, low operating costs

2. Large crushing ratio, excellent product particle shape

3. Wear-resistant and durable, easy maintenance

4. Intelligent control, stable operation

Fine crusher

fine crushing machine

fine crusher price

small fine crusher

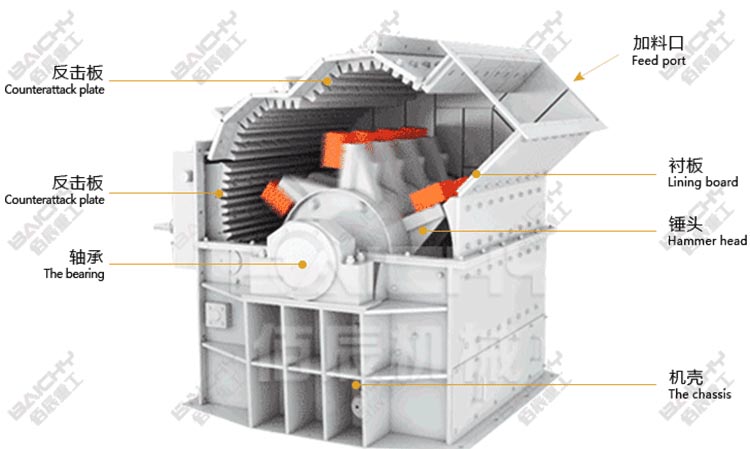

1. Rotor assembly: The core component of the equipment, including the main shaft, rotor disc, hammer disc, and hammers, responsible for material acceleration and initial crushing.

2. Impact plate system: Composed of high-manganese steel impact liners and impact frames, providing the main crushing working surface.

3. Housing and liners: Including the upper cover, lower body, and internal wear-resistant liners, forming the crushing workspace.

4. Adjustment device: Hydraulic or mechanical discharge particle size adjustment system to control the final product particle size.

5. Transmission system: Power transmission device composed of motor, pulleys, and V-belts.

6. Hydraulic opening system: Hydraulic opening device for easy equipment inspection and maintenance.

7. Intelligent control system: Automatic control system composed of PLC control cabinet, sensors, and monitoring instruments.

Fine crushers are widely used in many fields, including mining, metallurgy, construction, chemical industry, pharmaceuticals, food, etc., and are used to process various ores, rocks, construction waste, chemical raw materials, pharmaceutical intermediates and other materials.

1. High-Speed Projection and Kinetic Energy Acceleration

The material enters the crushing chamber, is captured by the high-speed rotor, and is violently accelerated, then projected at high speed along the tangential direction.

2. First Stage Crushing: Stone-on-Metal Impact

The material impacts the upper impact liner at high speed, achieving powerful initial crushing. This stone-on-metal process is the main crushing mechanism and is suitable for processing medium to high-hardness materials.

3. Material Collision: Stone-on-Stone Shaping

The rebounding material collides with subsequent material at high speed within the chamber, resulting in secondary stone-on-stone crushing and shaping. The finished product has excellent particle shape and extremely low needle-like and flaky content.

4. Cyclic Screening and Qualified Discharge

The material undergoes multiple impacts and collisions within the chamber, and its particle size gradually decreases. Qualified material is discharged from the bottom, while unqualified material continues to be crushed in a cycle until it meets the specifications.

| Model | Feeder Opening Size(mm) | Feeding Size(mm) | Output Size(mm) | Capacity of Cement(t/h) | Capacity of Limestone(t/h) | Motor Power(kw) |

| PCX-0804 | 400X185 | < 120 | < 3(85%) | 20-30 | 35-45 | 45 |

| PCX-0806 | 500X250 | < 180 | 35-40 | 45-55 | 55 | |

| PCX-0808 | 550X330 | 35-45 | 55-65 | 55 | ||

| PCX-1010 | 1000X350 | 45-55 | 65-75 | 75 | ||

| PCX-1210 | 1200X400 | 50-100 | 80-100 | 110 | ||

| PCX-1212 | 1200X450 | < 5(85%) | 90-110 | 100-110 | 132 | |

| PCX-1414 | 1500X500 | < 190 | 100-150 | 100-150 | 160 | |

| PCX-1616 | 1600X550 | 170-210 | 190-250 | 250 | ||

| PCX-1818 | 1800X800 | 250-270 | 280-310 | 315 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery