|

Equipment |

ZSW6025 Vibrating feeder | PE400x600 Jaw Crusher | PF1007 Impact Crusher | 3YK1548 Vibrating Screen | Belt Conveyor |

|

Raw materials |

This stone plant can crush more than 120 kinds of ore materials such as Feldspar, limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size |

0-300mm |

|

Capacity |

30-60t/h |

|

Finished product |

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

|

Design requirements

|

1. What material will be crushed? 2. What is the required production capacity? 3. What are the required specifications for the finished product? |

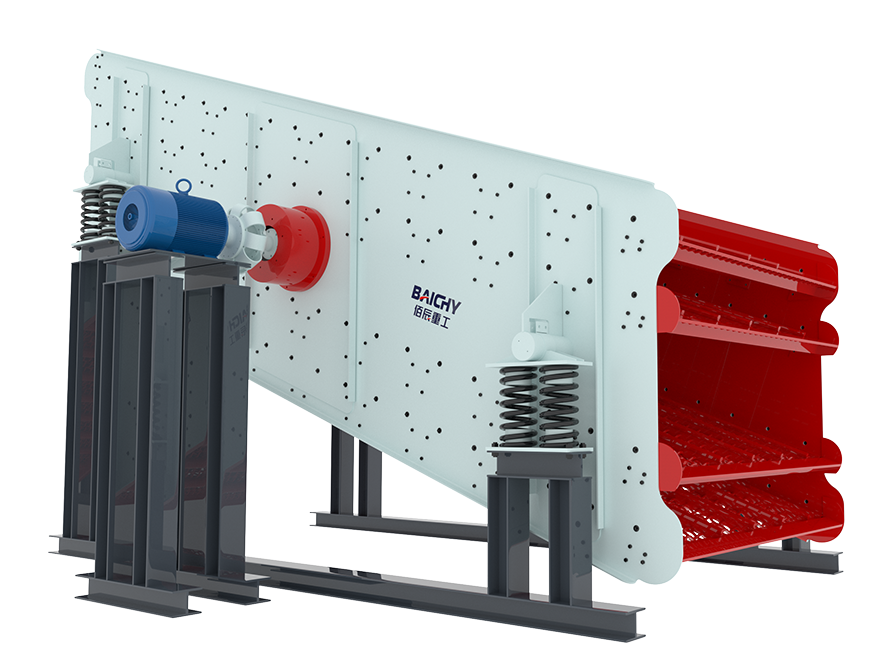

YK series vibrating screens are widely used in quarries for screening sand and gravel, as well as product grading in industries such as coal dressing, ore dressing, building materials, power, and chemical industry. Its efficient and stable screening performance has been recognized by the majority of users.

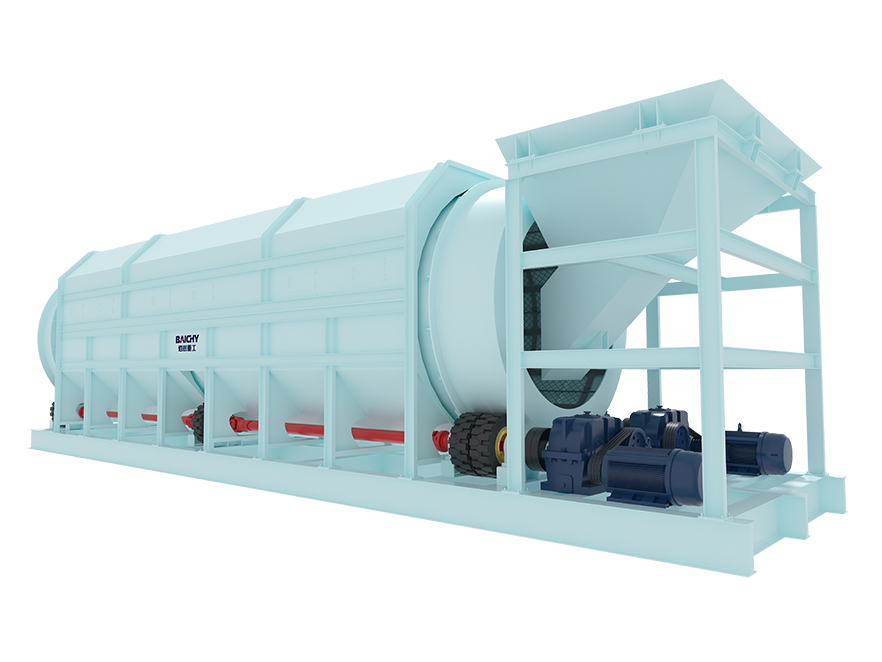

As a widely used screening equipment, the drum screen plays an important role in many fields due to its high efficiency, convenience, and environmental protection. The working principle is to control the sorting of materials based on the particle size.

In industries like sand and gravel aggregates, mining, and construction waste recycling, production capacity requirements of 30-60 t/h are common. However, traditional crushing solutions often face the following problems:

• Insufficient capacity: Small crushers (<30 tons) have low efficiency, impacting production schedules; large equipment (>100 tons) requires high investment and low utilization rates.

• Energy waste: Fixed production lines have high idle rates and poor mobility, making them incapable of adapting to flexible operational needs.

• Unstable product quality: Improper crushing ratios result in a high number of needle-like particles, impacting concrete strength.

Modular design + intelligent control provide cost-effective crushing stations with a capacity of 30-60 t/h. These crushing stations balance efficiency, energy saving, and mobility, making them suitable for small and medium-sized sand and gravel plants and construction waste recycling projects.

• Customer Requirements: 50 t/h, finished product for a commercial concrete mixing plant.

• Solution: PE400×600 jaw crusher + PYB900 Spring cone crusher + 3YK1860 vibrating screen.

• Results: Actual production capacity of 55-60 t/h, flake content <8%, and a 30% increase in annual customer revenue.

Further reading: How To Choose A Suitable Mining Stone Crusher? | Overseas 250tph Aggregate Production Line EPC General Contracting Case

Yes! However, we recommend a jaw crusher + cone crusher combination with manganese steel wear plates, which can extend equipment life by 40%.

• Small- to medium-sized sand and gravel plants (300,000-500,000 tons annual output)

• Construction waste recycling projects

• Small- to medium-sized mining operations

• Aggregate supply for municipal projects

• Ultra-large mines (100 tons/hour or higher recommended)

• Temporary projects (mobile crushing plants recommended)

Judgment Criteria: If daily demand is between 300-600 tons, this capacity range is the most economical choice.

• Material Hardness (Granite has a 15-20% lower production capacity than limestone)

• Feed Size (recommended within 500mm)

• Equipment Maintenance Status (Regular maintenance can maintain over 95% production capacity)

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.