YGM High-Pressure Grinding Mill is an advanced powder processing equipment based on high-pressure suspension roller grinding technology. It is mainly used for medium-fine powder grinding of medium-hardness and below materials (Mohs hardness ≤ 9.3), and is widely used in mining, building materials, chemical industry,metallurgy, and other fields.

Adopting a high-pressure spring booster system, by enhancing the grinding pressure of the grinding roller on the material (30%-50% higher than the traditional Raymond mill), a more efficient and finer crushing effect is achieved.

The material is subjected to multi-layer grinding + airflow classification between the grinding roller and the grinding ring, and the finished product fineness can be flexibly adjusted within the range of 80-425 mesh.

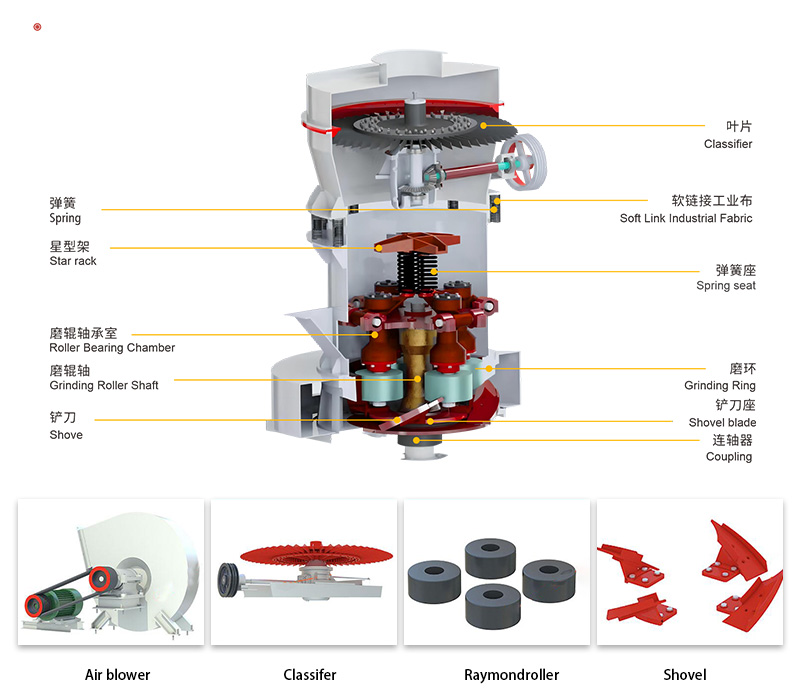

Grinding production line

YGM High Pressure Grinding Mill

Grinding equipment parts

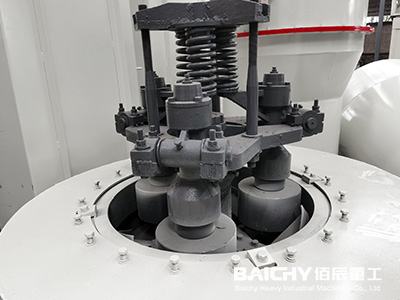

Roller working condition

YGM85, YGM95, and YGM130 are all hot-selling models of YGM high-pressure roller mills; these models have their own characteristics in terms of processing capacity, crushing fineness, energy consumption, etc., and users can choose according to their own needs.

• YGM75: Small model, suitable for small batch trial production or low storage (such as calcite, talc) processing,capacity ≤ 3t/h.

• YGM95: Medium-sized main chassis, balanced capacity (2.1-5.6t/h) and carbon dioxide, widely used in building materials, chemical industry, and other fields.

• YGM130: Large high-pressure mill, with a processing capacity of up to 2.5-9.5t/h, suitable for large-scale crushing of high-hardness materials such as iron ore and quartz sand.

1200kg high-pressure spring boosting technology, finished product fineness 80-425 mesh, 10%-20% higher output than Raymond mill; intelligent grading system ensures uniform particle size.

Optimized structural design, energy consumption reduced by 15%-30%; pulse dust removal + silencer system, dust -20mg/m³, noise ≤75 decibels, environmental protection up to standard.

High manganese steel/alloy steel core components, life 8000-10000 hours; hydraulic pressure regulation + intelligent lubrication, extremely low failure rate.

PLC automatic control, remote monitoring; modular design, maintenance efficiency increased by 60%, reducing downtime losses.

YGM high-pressure grinding mill is based on high-pressure suspension roller grinding technology, and achieves material crushing through the following mechanisms:

High-pressure grinding: The main motor drives the grinding roller to revolve around the main shaft, and the grinding ring is pressed and rolled under the action of centrifugal force and high-pressure spring (pressure up to 1200kg), and the material is crushed into fine powder.

Grading and separation: The ground powder is sent to the classifier by airflow, and the speed regulating motor adjusts the impeller speed to separate qualified fine powder (80-425 mesh adjustable), and the coarse powder falls back and re-grinds to avoid over-crushing.

1. Feeding stage: The material is evenly fed into the grinding area between the grinding roller and the grinding ring through the feeder.

2. High-pressure grinding stage: The grinding roller repeatedly squeezes and shears the material to achieve multi-stage crushing.

3. Airflow sorting stage: The blower blows the powder to the classifier, the dynamic impeller sorts the fine powder, and the qualified products enter the cyclone collector.

4. Finished product collection and dust removal: Fine powder is collected by a pulse dust collector and discharged into purified air (dust-20mg/m³).

5. Circulation system: Coarse powder that does not meet the standards is returned to the grinding area for further crushing, forming a closed-loop circulation.

| Model | Roller No. | Roller Size (mm) | Grind Ring Inner Dia. Height & Length(mm) | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| YGM65 | 3 | 210×150 | 650×150 | ≤ 15 | 0.613-0.033 | 0.4-1.8 | 15 | 4100×3300×4500 |

| YGM75 | 3 | 260×150 | 780×150 | ≤ 15 | 0.613-0.033 | 1-3 | 18.5 | 4300×3500×5100 |

| YGM85 | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.033 | 1.2-4 | 22 | 5300×4100×5200 |

| YGM85B | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.03 | 1.2-3.5 | 22 | 5300×4100×5200 |

| YGM95 | 4 | 310×190 | 950×190 | ≤ 25 | 0.613-0.033 | 2.1-5.6 | 45 | 7100×5900×7900 |

| YGM130 | 5 | 410×230 | 1280×230 | ≤ 30 | 0.613-0.033 | 2.5-9.5 | 90 | 7900×8000×9700 |

| YGM160 | 6 | 450×300 | 1600×300 | ≤ 35 | 0.613-0.033 | 8-16 | 132 | 12550×5700×8355 |

| YGM190 | 6 | 500×330 | 1900×330 | ≤ 40 | 0.613-0.033 | 18-36 | 250 | 11200x8530x9685 |

• Check whether the feed amount is uniform to avoid too much or too little.

• The grinding roller and grinding ring are seriously worn and need to be replaced or repaired.

• The analyzer speed is abnormal; adjust or check the transmission system.

• Clean or adjust the damper if the air duct is blocked or the fan air volume is insufficient.

• Adjust the analyzer speed (the higher the speed, the finer the fineness).

• Check the wear of the grading blades and replace them if necessary.

• Ensure that the fan air volume matches to avoid coarse or fine powder being carried away.

• Check whether the anchor bolts are loose and tighten the fixing parts.

• The roller bearing is damaged or insufficiently lubricated, and oil or replacement of the bearing is required.

• Metal impurities are mixed in the material, and the crushing chamber should be cleaned when the machine is stopped.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery