Double-Stage Hammer Crusher has become an indispensable and important equipment in the industrial field due to its efficient, uniform, and reliable crushing performance and wide range of applications.

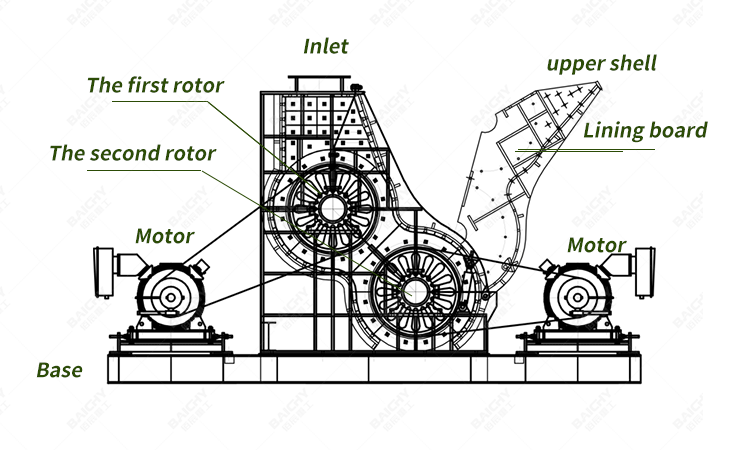

The double-stage hammer crusher is a high-efficiency fine crushing equipment developed by our company, featuring a unique double-rotor, screenless design. The equipment utilizes a two-stage series rotor system to achieve multi-stage crushing of materials, significantly increasing the crushing ratio and providing uniform and controllable (adjustable range 3-8mm) finished product particle size. The machine has a compact structure and uses wear-resistant alloy hammerheads and high-strength liners, making it suitable for fine crushing of various medium-hardness materials.

1. Double-Rotor System: Main drive device, two rotors rotate in the same direction but at different speeds.

2. High-Chromium Alloy Hammerheads: Main crushing components, wear-resistant and impact-resistant.

3. Adjustable Impact Plate: Works with the hammerheads to achieve impact crushing; the gap is adjustable to control the output particle size.

4. Heavy-Duty Frame: Overall welded structure with reinforced design in high-stress areas.

5. Hydraulic Opening Device: Facilitates inspection and maintenance, reducing downtime.

6. Transmission System: Motor drives the rotor via V-belts; overload protection device ensures safety.

7. Base and Vibration Damping Device: Reduces vibration and noise during equipment operation.

two stage hammer crusher

Hammer double stage crusher

Two Stage Stone Crushing Plant

Two-stage crusher for sale

1. High-Efficiency Double Crushing: The double-rotor series design allows materials to be coarsely crushed by the first-stage rotor and then immediately finely crushed by the second-stage rotor, increasing crushing efficiency by more than 30%.

2. Uniform and Adjustable Particle Size: By adjusting the gap between the movable liner and the hammerheads, the output particle size can be easily controlled (adjustable within the range of 3-8mm), meeting different production needs.

3. Wear-Resistant and Durable: Uses high-chromium alloy composite hammerheads and high-manganese steel liners; the service life of key components is extended by 40%, reducing maintenance costs.

4. Non-Clogging Design: The unique screenless, multi-row hammerhead arrangement prevents clogging, even when processing materials with slightly higher moisture content, ensuring strong adaptability.

Double-Stage Hammer Crusher is suitable for crushing medium-hard materials with a compressive strength not exceeding 150 MPa and a moisture content of less than 12%, such as limestone, bluestone, coal gangue, shale, gypsum, and construction waste.

The double-stage hammer crusher achieves efficient fine crushing of materials through a two-stage series crushing process. Its working principle can be broken down into the following four consecutive steps:

First-stage impact crushing

The material enters the first crushing chamber through the feed opening.

It is immediately subjected to a violent impact from the hammers on the high-speed rotating rotor of the first stage, resulting in initial crushing.

First-stage impact crushing (rebound)

After gaining kinetic energy, the crushed material strikes the impact plate inside the machine chamber at high speed.

Under the combined action of impact force and rebound force, the material undergoes secondary crushing and changes direction.

Second-stage fine crushing

The material, after the first stage of crushing, enters the second crushing chamber.

Here, the rotor has a higher linear speed and the hammers are more densely arranged, causing the material to undergo a more intense impact-rebound cycle, resulting in further fine crushing.

| Model | Feeding Size(mm) | Discharge Size | Production Capacity(t/h) | Allow Material Moisture Content | power(kw) | Size(mm) |

|---|---|---|---|---|---|---|

| 2PC2000×1600 | ≤200 |

All size below 3mm: in general about 50% is 0.5~0.075mm , 35% is 0.6~2mm and the rest is 2~3mm. The discharge particle size can be adjusted as needed |

250-300 | <20% | 355+355 | 6410×3413×4260 |

| 2PC1600×1400 | ≤180 | 120-180 | 220+220 | 6000×3100×3900 | ||

| 2PC1400×1200 | ≤150 | 100-120 | 132+160 | 5800×2658×3210 | ||

| 2PC1200×1000 | ≤130 | 80-100 | 110+132 | 4086×2230×2550 | ||

| 2PC1100×1000 | ≤130 | 60-90 | 90+110 | 4086×2030×2337 | ||

| 2PC900×800 | ≤100 | 50-70 | 55+75 | 3950×1750×2280 | ||

| 2PC800×700 | ≤100 | 45-60 | 55+55 | 3485×1400×2254 | ||

| 2PC600×600 | ≤100 | 20-30 | 22+22 | 2875×1300×1650 | ||

| 2PC600×400 | ≤100 | 15-25 | 18.5+22 | 2350×926×1630 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery