The spring insurance system is an overload protection device that provides "spring-type" iron release protection for foreign matter (iron blocks). Under normal use, the equipment has a trouble-free operation rate of more than 95%.

The PY Series Spring Cone Crusher is a medium-fine crushing equipment that uses mechanical spring overload protection. It is widely used in mining, building materials, metallurgy, chemical industry and other industries. It is suitable for crushing medium and above hardness ores and rocks (such as granite, basalt, iron ore, etc.).

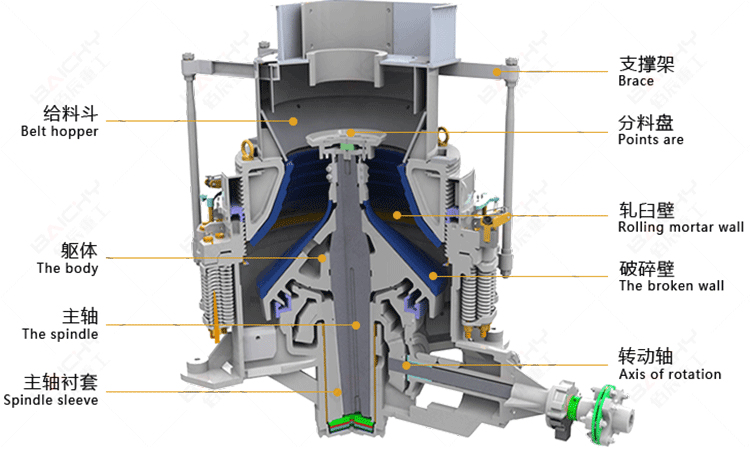

• Main frame: high-strength cast steel or welded structure to ensure equipment stability.

• Crushing chamber: It consists of a moving cone (movable cone) and a fixed cone (fixed liner). The liner is made of high manganese steel and has strong wear resistance.

• Transmission system: The motor drives the moving cone to perform a swing motion through a pulley, a horizontal shaft, and an eccentric sleeve to achieve material extrusion and crushing.

• Spring safety device: When unbreakable objects (such as iron blocks) enter the crushing chamber or are overloaded, the spring is compressed to enlarge the discharge port, and the foreign matter is automatically reset after being discharged to protect the equipment.

• Lubrication system: Use thin oil circulation lubrication to ensure long-term stable operation of bearings and gears.

spring cone crusher

PYB cone crusher

PY spring cone crusher

Cone Crusher Manufacturer

The PY series is usually divided into three chamber types to meet different crushing needs: PYB, standard type, coarse crushing, large feed inlet, small crushing ratio, high output; PYZ, medium type, medium crushing, taking into account both output and fineness; PYD, short head type, fine crushing, finer discharge particle size, suitable for sand making.

Common specifications: PYB600, PYB900, PYB1200, PYB1750, PYB2200 (number represents the bottom diameter of the moving cone, unit: mm).

• Mining crushing: secondary or tertiary crushing of iron ore, copper ore, gold ore, etc.

• Building materials industry: production of aggregates such as granite, basalt, limestone, etc.

• Sand making: Short head type (PYD) can be used for fine crushing of machine-made sand.

Spring cone crusher vs hydraulic cone crusher, the price is 30%~50% lower than that of hydraulic cone crusher, suitable for projects with limited budget; no complex hydraulic system, low technical requirements for operators; in production lines with low output requirements (≤500t/h), the cost performance is outstanding.

• Ore crushing: PYB spring cone crusher is widely used in the metallurgical industry to crush various ores, such as iron ore, copper ore, etc. Its powerful crushing force and high crushing efficiency can meet the metallurgical industry's demand for raw material crushing.

• Construction aggregate production: PYB spring cone crusher can be used to produce construction aggregates, such as crushing limestone, granite, and other rocks to meet the construction industry's demand for aggregates.

The PYB spring cone crusher is mainly composed of a frame, a transmission device, an empty eccentric shaft, a bowl-shaped bearing, a crushing cone (moving cone), an adjustment device, an adjustment sleeve, a spring, and a hydraulic station for adjusting the discharge port. Among them, the moving cone is supported on a spherical bearing and fixed on a suspended vertical shaft, which is placed in an eccentric sleeve, and the eccentric sleeve is placed on a thrust bearing.

• The swinging motion of the moving cone causes the gap between it and the fixed cone to move closer and farther from time to time.

• When the moving cone approaches the fixed cone, the gap between the two is reduced, which produces extrusion, shearing, and impact effects on the material, thereby achieving material crushing.

• The crushed material is discharged through the discharge port under the action of gravity and crushing force, completing the entire crushing process.

| Model |

Cone Diameter (mm) |

Max. Feed Size (mm) |

Outlet Setting Size (mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

| PYB-600 | 600 | 66 | 12-25 | 15-25 | 30 | 1740X1225X1940 |

| PYD-600 | 600 | 36 | 3-13 | 5-23 | 30 | 1740X1225X1940 |

| PYB-900 | 900 | 115 | 15-50 | 50-90 | 55 | 1990X1640X2380 |

| PYZ-900 | 900 | 60 | 5-20 | 20-65 | 55 | 1990X1640X2380 |

| PYD-900 | 900 | 40 | 3-13 | 15-50 | 55 | 1990X1640X2380 |

| PYB-1200 | 1200 | 145 | 20-50 | 110-200 | 110 | 2805X2300X2980 |

| PYZ-1200 | 1200 | 100 | 8-26 | 50-150 | 110 | 2805X2300X2980 |

| PYD-1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 2805X2300X2980 |

| PYB-1750 | 1750 | 215 | 25-60 | 280-480 | 155-160 | 3610X2950X4185 |

| PYZ-1750 | 1750 | 185 | 10-30 | 115-230 | 155-160 | 3610X2950X4185 |

| PYD-1750 | 1750 | 85 | 5-15 | 75-230 | 155-160 | 3610X2950X4185 |

| PYB-2200 | 2200 | 300 | 30-60 | 590-1000 | 260-280 | 4790X3430X5080 |

| PYZ-2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 4790X3430X5080 |

| PYD-2200 | 2200 | 110 | 5-16 | 120-370 | 260-280 | 4790X3430X5080 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery