![]()

Talc grinding is a core step in the production process, directly affecting the fineness, purity, and performance of the finished product. A complete talc grinding production line typically includes crushing, grinding, grading, collection, and packaging. The following details the key grinding processes.

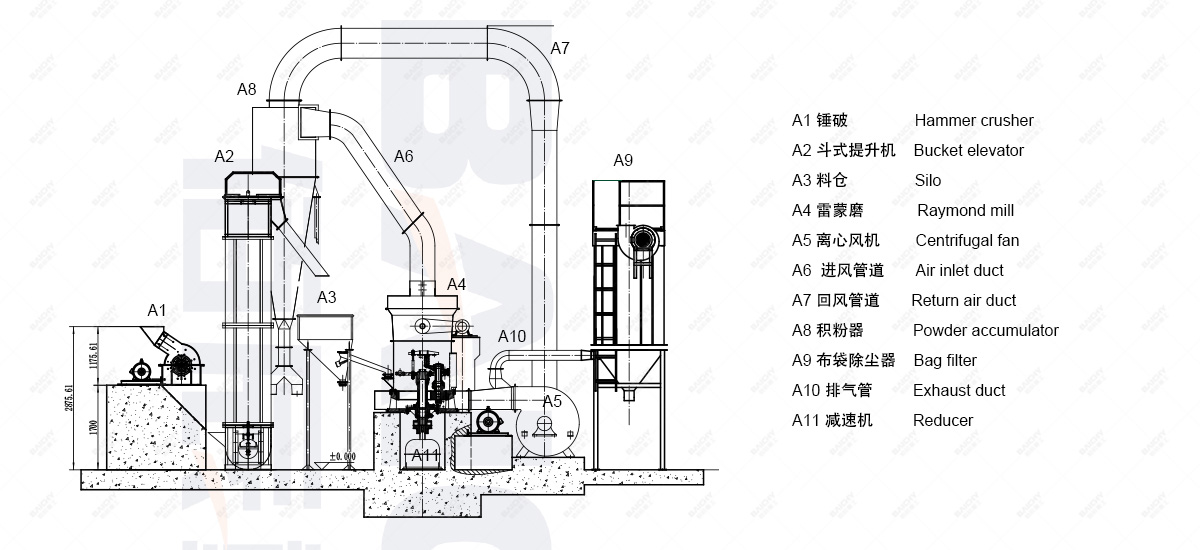

Talc ore typically contains impurities and is large (10-30 cm). It must first be coarsely crushed in a jaw crusher or hammer crusher to a size of 1-3 cm. It is then pre-ground in a Raymond mill or vertical mill to achieve a feed particle size suitable for fine grinding (typically ≤ 2 mm). Key Equipment: Jaw Crusher, Hammer Crusher, Vibrating Screen

Depending on the required fineness of the finished product (325-3000 mesh), different grinding equipment can be selected:

Raymond Mill (R-Type Pendulum Mill)

• Applicable Fineness: 80-400 mesh (180-38μm)

• Working Principle: Grinding rollers crush the talc under centrifugal force. The talc is then classified by an analyzer, with the coarse powder returning to the regrind and the fine powder entering the collection system.

Features: Low energy consumption, suitable for processing medium-fine powders, but with lower efficiency for ultrafine powders (above 800 mesh).

The ground talc powder is separated by particle size using an air classifier or cyclone separator:

• Qualified fine powder is collected in a pulse dust collector (such as a bag filter) to ensure a recovery rate of ≥99%.

• Coarse powder: Returned to the mill for re-grinding, forming a closed-loop cycle and improving utilization.

Key equipment: Turbine classifier, cyclone powder collector, pulse dust collector

The ground talc powder is packaged by an automatic packaging machine according to specifications (25kg/bag, ton bags, etc.) or stored in a silo for further processing.

Adopting advanced vertical mills, Raymond mills, or air jet mills, we ensure talc powder fineness ranges from 325 to 3000 mesh, meeting the needs of various industries.

Equipped with a pulse dust removal and noise reduction system, it complies with national environmental protection standards and achieves green production.

A PLC intelligent control system monitors production data in real time, improving operational stability and reducing labor costs.

Integrated crushing, grinding, grading, and packaging solutions can be customized to meet customer needs, improving production efficiency.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery