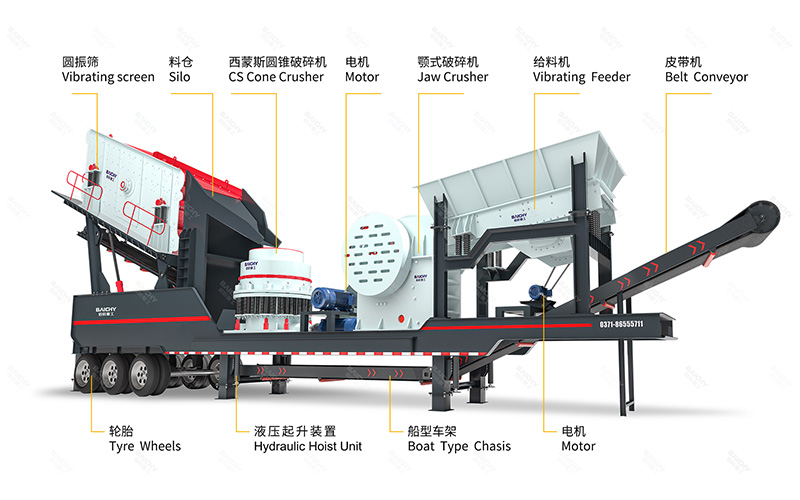

Four-in-One Mobile Crushing Station is a highly integrated modular crushing and screening equipment, which consists of four core modules: feeder, coarse crushing (jaw crusher), medium crushing (cone crusher/impact crusher) , and screening machine, which can complete the crushing, screening and transportation of materials in an integrated manner.

• Mining: Processing high-hardness rocks (such as granite and basalt), requiring multi-stage crushing.

• Construction waste recycling: coarse crushing + fine crushing + screening integrated processing of concrete, bricks, and tiles.

• Large sand and gravel aggregate plant: requires the simultaneous production of multiple specifications of finished products (such as 0-5mm, 5-10mm, 10-20mm).

Selection conditions: projects with complex raw materials, strict requirements on finished product particle size, and frequent site transfers.

Four-combination mobile crushing plant

Mining Mobile Crusher price

Sand and Gravel Aggregate Crusher

Mobile Construction Waste Crushing plant equipment

The four-combination mobile crushing station integrates the four modules of feeding, coarse crushing (jaw crusher), medium crushing (cone crusher/impact crusher), and screening to realize multi-stage crushing and screening integrated operation, which is suitable for processing high-hardness materials or complex particle size requirements.

The standard mobile crusher usually only includes a basic combination of single-stage crushing (such as a jaw crusher) or crushing + screening, with a simpler structure, suitable for medium and low-capacity scenarios of a single material.

The core difference lies in the functional integrity and applicable working of the four-combination station emphasizes "full-process closed-loop processing", and the standard station focuses on "flexible single-point breakthrough".

• Full-process integration: save intermediate transportation costs and improve production efficiency by 30 %+.

• Closed-loop circulation system: return materials after screening and then crushing, and the qualified rate of finished products is >95%.

• Customized configuration: flexible adjustment according to material hardness (select cone crusher/impact crusher) and production capacity (50-500t/h).

Customer Case: A construction waste treatment project used a four-combination station to process concrete blocks into recycled aggregates in one step, which were directly used for roadbed paving, saving 40% of costs.

The main structure of the four-combination mobile crushing plant includes the frame part, the eccentric shaft rotating part, the crushing chamber working part, the safety device, and the discharge port adjustment device. Among them, the eccentric shaft rotating part is the main part for transmitting power, which is composed of components such as the movable jaw, eccentric shaft, and bearings; the crushing chamber working part is composed of components such as the fixed jaw plate and the movable jaw plate, which is the main working area for crushing materials.

The four-combination mobile crushing plant has been widely used in many fields, such as the recycling of concrete and garbage, the treatment of construction waste, quarries, coal mining, etc. These application cases fully demonstrate the efficiency and flexibility of the four-combination mobile crushing station.

| Model | YDPZ46-1007 | YDPZ46-900 | YDPZ57-1210 | YDPZ57-75 | YDPZ96-1214 | YDPZ96-160 |

| Vibrating Feeder | ZSW0625 | ZSW0625 | ZSW8530 | ZSW8530 | ZSW9638 | ZSW9638 |

| Primary Jaw Crusher | PE400×600 | PE400×600 | PE500×750 | PE500×750 | CJ96 | CJ96 |

| Feeding Size (mm) | ≤350 | ≤350 | ≤425 | ≤425 | ≤480 | ≤480 |

| Feeding Size (mm) | 15-60 | 15-60 | 40-130 | 40-130 | 60-160 | 60-160 |

| Secondary Crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher |

| Model | PF1007 | PYB900 | PF1210 | CS75 | PFW1214 | CS160 |

| Feeding Size (mm) | ≤250 | ≤115 | ≤400 | ≤150 | ≤430 | ≤205 |

| Capacity (t/h) | 15-60 | 15-90 | 70-130 | 27-163 | 100-180 | 109-349 |

| Vibrating Screen | 2/3/4YK1237 | 2/3/4YK1237 | 2/3/4YK1848 | 2/3/4YK1848 | 2/3/4YK1860 | 2/3/4YK1860 |

| Belt Conveyor | B500x8m | B650 | B650 | B650 | B800 | B800 |

| Capacity (t/h) | 15-60 | 15-60 | 60-100 | 100-150 | 150-180 | 180-300 |

| Overall Size(mm) | 11500*2050*5400 | 11500*2050*5400 | 15800*2300*5850 | 15800*2300*5850 | 18000*2700*7650 | 18000*2700*7650 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery