Limestone, as an important industrial raw material, is widely used in building materials, chemicals, metallurgy, environmental protection, and other fields. To meet the fineness requirements of various industries, limestone grinding production lines are a key step in the processing process.

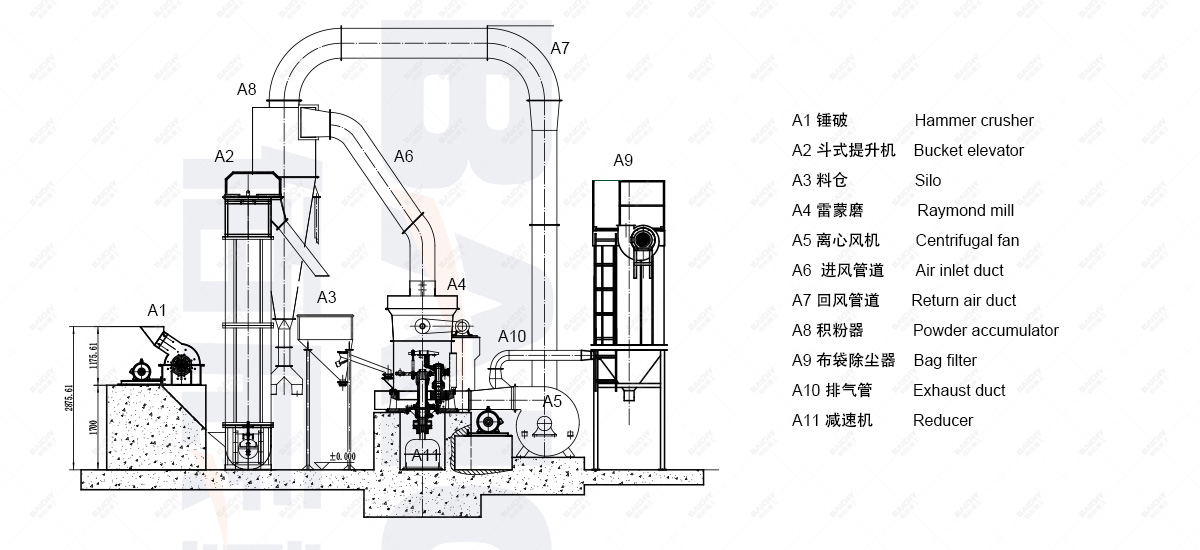

A limestone grinding production line typically includes crushing, grinding, grading, and collection to ensure uniform fineness and stable output of the finished product.

• Large limestone lumps are first crushed in a jaw crusher or hammer crusher to reduce the material to particles ≤30mm, improving subsequent grinding efficiency.

The crushed limestone enters a grinding mill for fine grinding. Common equipment includes:

• Raymond mill: Suitable for 80-600 mesh fineness, with a production capacity of 1-50 tons/hour and high cost-effectiveness.

• Vertical grinding mill: Suitable for large-scale production (50-500 tons/day), with low energy consumption and strong environmental protection. • Ultrafine Grinding Mill: Capable of producing 800-3000 mesh, suitable for high-value-added products.

• The ground material is screened by a classifier, and finished products that meet the required fineness are collected in a pulse dust collector, ensuring dust-free and improving recovery rates.

• Small production lines (1-10 tons/hour) are suitable for start-ups.

• Large production lines (50-500 tons/day) are suitable for large-scale production in industries such as building materials and chemicals.

• General building materials: 80-325 mesh

• Fine chemicals: 400-2500 mesh

Using new grinding roller technology and an optimized drive system, energy consumption is reduced by 30% compared to traditional grinding equipment, significantly reducing electricity costs.

The production line adopts a sealed structure, effectively preventing dust from escaping and creating a cleaner working environment.

• Coarse powder (80-325 mesh): Suitable for use in cement, concrete additives, and other building materials industries.

• Fine powder (400-2500 mesh): Suitable for chemical fillers in plastics, coatings, rubber, and other industries.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery