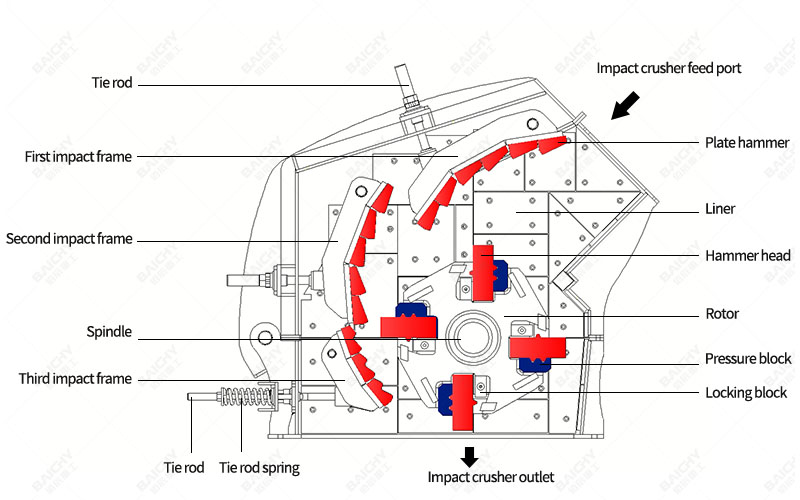

PF series impact crusher has a compact structure, and large crushing ratio, and adopts multi-cavity uniform crushing technology, which is suitable for crushing hard rock and has a better crushing effect.

An impact crushing line is a complete crushing production line composed of an impact crusher as the core, combined with a feeder, vibrating screen, conveyor, dust removal system, and other equipment. It is suitable for medium and fine crushing of medium-hard and below materials (such as limestone, granite, concrete, construction waste, etc.), and is widely used in:

• Mining (granite, basalt, iron ore, etc.)

• Sand and gravel aggregate production (machine-made sand, gravel, etc.)

• Construction waste recycling (concrete, bricks, asphalt recycling)

• Cement, metallurgy, chemical industry, and other industries

• Efficient crushing, large output

• Strong adaptability, can handle a variety of materials

• Modular design, flexible configuration

• Intelligent control reduces operating costs

Hot-selling models: PF1007 | PF1010 | PF1210 | PF1214 | PF1315

Impact Crusher In Workshop

Impact Crusher Side display

Impact Crushing Plant In somalia

Impact Crushing Plant In Harbin

The impact crushing line has become the mainstream choice in the modern crushing industry due to its high efficiency, flexibility, and energy saving. Whether it is mining, sand and gravel production, or construction waste recycling, choosing a suitable impact crushing line can greatly improve production efficiency and reduce operating costs.

PF series impact crusher is mainly used for medium and fine crushing of various medium hardness materials and is widely used in metallurgy, mining, chemical industry, building materials, highways, railways, water conservancy, and other industries. Especially when producing stones for high-speed highways, hydropower, construction, and other industries, the equipment performs well.

| Model |

Feeder opening size(mm) |

Max feeding size(mm) |

Rotor size D*L(mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

| PF1007 | 450X730 | ≤250 | Φ1000X700 | 15-60 | 45 | 2330x1700x2560 |

| PF1010 | 400X1080 | ≤300 | Φ1000X1050 | 50-90 | 55 | 2330x2010x2560 |

| PF1210 | 450X1150 | ≤300 | Φ1250X1050 | 70-130 | 90 | 2640x2010x2850 |

| PFW1210 | 450X1150 | ≤300 | Φ1250X1050 | 75-140 | 90 | 2900x2000x2600 |

| PFW1214 | 450x1460 | ≤350 | Φ1250X1400 | 100-180 | 132 | 2900x2400x2600 |

| PFW1315 | 550X1520 | ≤350 | Φ1320X1500 | 130-220 | 200 | 3300x2650x2650 |

| PFW1320 | 550X1900 | ≤400 | Φ1320X2000 | 160-350 | 250 | 3350x3175x2720 |

| PFW1515 | 930x1550 | ≤600 | Φ1500X1500 | 200-400 | 280 | 3450x2750x3010 |

| PFW1520 | 930X2040 | ≤700 | Φ1512X2000 | 300-450 | 355 | 3450x3250x3010 |

| PFW1820 | 1620X2040 | ≤700 | Φ1800X2000 | 500-800 | 2 x 315 | 4400x3750x3900 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery