Slag (blast furnace slag, steel slag, etc.) is a byproduct of the metallurgical industry. Traditional storage not only occupies land but also pollutes the environment. Using a slag grinding line, it is processed into fine slag powder (specific surface area ≥420 m²/kg), which can be widely used in:

• Cement admixtures: Replace 30%-50% of cement clinker, reducing production costs.

• Concrete admixtures: Improve concrete strength, durability, and workability.

• Environmentally friendly building materials: Such as slag bricks and roadbed materials, which achieve resource recycling.

Industry Trends: With the advancement of the "Dual Carbon" policy, slag grinding lines have become a key investment direction for steel companies' transformation and upgrading due to their low energy consumption and high added value.

• Drying: The moisture content of the slag must be controlled to ≤1% (vertical mills can perform both drying and grinding).

• Iron Removal: A magnetic separator removes metallic impurities, protecting the grinding equipment.

| Equipment Type | Advantages | Applicable Scenarios |

| Vertical Roller Mill | Low power consumption (~40 kWh/t), small footprint | Medium- to large-scale production lines (annual output ≥ 300,000 tons) |

| Ball Mill | Low investment, easy maintenance | Small production lines or projects with limited budgets |

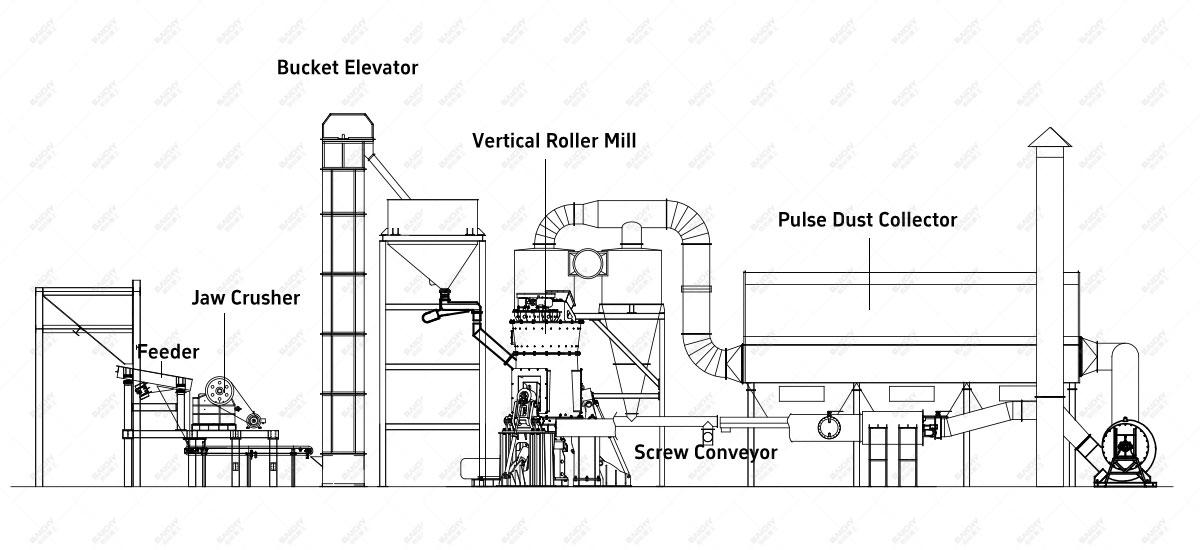

• Vertical Mill System: Integrated drying and grinding, high efficiency, but requiring a larger equipment investment.

• Ball Mill + Classifier: Requires a dryer and is suitable for applications requiring less fineness.

• High-Efficiency Bag Dust Collector: Dust emissions ≤ 20mg/m³, meeting environmental requirements.

• Automated Packaging System: Supports bulk and pallet shipments, reducing labor costs.

Industrial waste slag (blast furnace slag, steel slag, etc.) is converted into high-value-added slag powder, which can be used as a replacement for cement clinker or concrete admixtures, achieving a "waste-to-treasure" transformation and a comprehensive resource utilization rate exceeding 95%.

Slag powder has a stable market price of 120-180 yuan/ton, while processing costs are only 60-80 yuan/ton. The investment payback period is short (2-3 years), making it particularly suitable for supporting steel mill construction and extending industrial chain profits.

Advanced equipment such as vertical mills achieves dual-standard compliance, with power consumption as low as 40 kWh/t (30% less than traditional ball mills) and dust emissions ≤20 mg/m³, helping companies meet "dual carbon" emission reduction requirements.

The automated control system and modular design enable flexible configurations with an annual production capacity of 50,000 to 1 million tons. The equipment has a lifespan of over 80,000 hours, stable operation, and low maintenance costs.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery