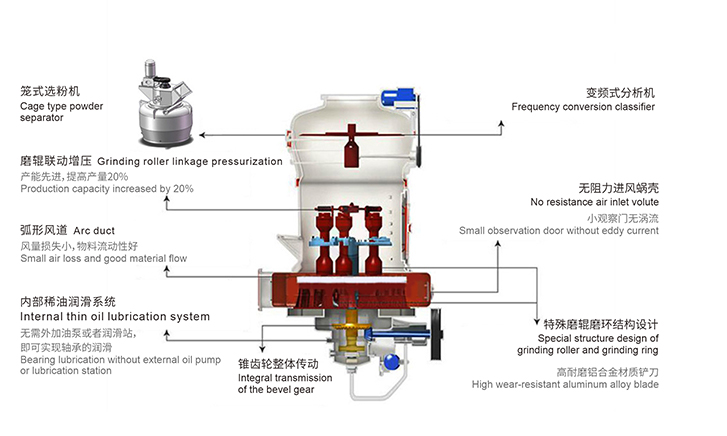

MTW European Trapezium Grinding Mill is a medium-to-large industrial grinding equipment designed with advanced European technology. It is mainly used for grinding non-metallic minerals (such as limestone, calcite, barite, talc, etc.), and is suitable for building materials, chemical industry, metallurgy, and other fields.

Trapezium grinding roller and grinding ring design

• Adopt curved trapezium grinding roller and annular grinding track to increase the grinding contact area, improve grinding efficiency, and reduce energy consumption.

• The number of grinding rollers is usually 4-6, and the grinding force is adjusted by the hydraulic pressure system to adapt to materials of different hardness.

High-efficiency grading system

• Built-in turbine classifier can accurately control the fineness of the finished product (adjustable within the range of 80-400 mesh), avoid over-crushing, and ensure particle uniformity.

Energy saving and environmental protection

• Adopting variable frequency speed regulation and a centralized dust removal system (such as a pulse bag dust collector), it complies with European CE environmental protection standards, and the dust emission concentration is less than 30mg/m³.

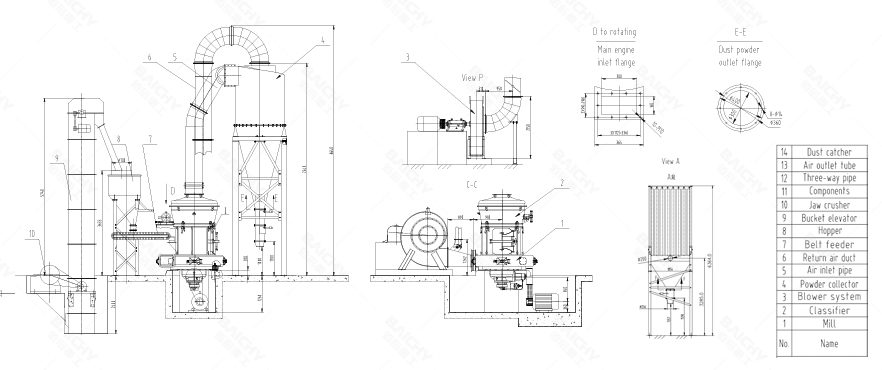

Grinding production line

MTW Trapezium Grinding Mill

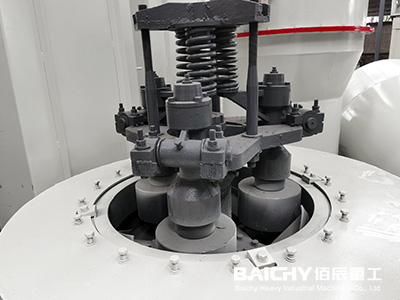

Grinding equipment parts

Raymond grinding roller

• MTW110 is suitable for small and medium-sized production lines, with moderate processing capacity, suitable for occasions where the output requirements are not very high.

• MTW138 has improved processing capacity compared to MTW110T, suitable for medium-sized production lines.

• MTW175 has further enhanced processing capacity, suitable for large production lines, and can efficiently complete the grinding of a large number of materials.

As an upgraded product of the traditional Raymond mill, it has the advantages of high efficiency, energy saving and environmental protection, durability, and easy maintenance.

1. Material characteristics

Medium hardness non-metallic minerals: such as limestone, calcite, barite, talc, bentonite, gypsum, etc. (Mohs hardness ≤ 5).

Fineness requirement 80-400 mesh: suitable for fields with medium fineness requirements, such as building materials and chemicals.

Low moisture content: Feed moisture must be less than 6%. If the humidity is too high, drying equipment is required.

2. Capacity requirements

Medium and large-scale production: The capacity range of a single MTW mill is usually 3-50 t/h (depending on the model, such as MTW175 is about 5-15 t/h, MTW215 is about 15-30 t/h).

Continuous operation: suitable for industrial production lines that run continuously for 24 hours.

The curved trapezoidal grinding roller design increases the contact area, and the rolling efficiency is 30%-50% higher than that of the traditional Raymond mill, and the finished product fineness is uniform (80-400 mesh adjustable). The dynamic turbine classifier has a built-in high-precision grading wheel to avoid over-crushing, and the fineness can be flexibly adjusted (such as 325 mesh D97 pass rate ≥95%).

The energy consumption of the main machine is reduced by 20%-30%, and the bevel gear integral transmission and thin oil lubrication system are adopted, which saves electricity significantly. Wear-resistant parts (grinding roller/grinding ring) are made of high chromium alloy or ceramic composite materials, with a life of 800-1200 hours and lower maintenance costs.

PLC intelligent control system monitors current, temperature and other parameters in real time, automatically adjusts feed amount and grinding force, and reduces manual intervention.

The pulse dust removal system has dust emissions of <30mg/m³, which complies with EU CE and China GB16297 standards. The closed operation noise is <75dB (traditional >85dB), which is suitable for areas with strict environmental protection requirements.

1. Material crushing and transportation: Large pieces of material are first crushed to the required particle size by the jaw crusher, and then the materials are sent to the storage hopper by the elevator. Then, the materials are uniformly and quantitatively continuously fed into the main milling chamber through the vibrating feeder for grinding.

2. Grinding process: In the main grinding chamber, the material is subject to the combined action of the grinding roller and the grinding ring. The grinding roller device not only rotates around the central axis but also revolves around the grinding ring. At the same time, the grinding roller itself rotates due to friction. This movement mode causes the material to be strongly impacted and ground between the grinding roller and the grinding ring, thereby being crushed into fine powder.

| Model | Roller Size (mm) | Grind Ring Size DxH(mm) | Main Roller Speed (r/min) | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| MTW110 | 360×210 | 1100×210 | 120 | 30 | 0.038-1.6 | 4-12 | 55 | 8910×6950×9010 |

| MTW138 | 460×260 | 1380×260 | 96 | 35 | 0.038-1.6 | 8-20 | 110 | 9860×8340×10227 |

| MTW175 | 520×300 | 1750×300 | 75 | 40 | 0.038-1.6 | 20-35 | 200 | 13500×11500×9500 |

| MTW215 | 640×340 | 2150×340 | 65 | 50 | 0.038-1.6 | 30-50 | 280 | 13922×9810×13226 |

• Power supply problem: Check whether the voltage is stable and ensure that it meets the equipment requirements (usually 380V/50Hz).

• Motor failure: Test the insulation of the motor to check whether it is overloaded or burned.

• Protection device triggering: Check whether the thermal relay, circuit breaker, etc., are tripped, and try to restart after resetting.

• Feed blockage: Clean the residual material in the grinding chamber to avoid blocking the material when starting.

• Grinding roller/grinding ring wear: Check the degree of wear and replace it in time (it is recommended to check every 500-800 hours).

• Analyzer speed abnormality: Adjust the analyzer speed to a reasonable range (according to the material fineness requirements).

• Insufficient air volume: Check the operating status of the fan and whether the pipeline is leaking, and adjust the air door opening.

• Uneven feeding: Control the feeding speed to avoid excessive or intermittent feeding.

• Unstable foundation: Strengthen the foundation to ensure that the equipment is installed horizontally

• Loose bolts: Tighten the bolts of key parts such as grinding rollers and bearing seats.

• Bearing damage: Stop the machine to check the lubrication and wear of the bearings and replace them if necessary.

• Material hardness is too high: Confirm whether the material meets the equipment crushing hardness requirements (such as Mohs hardness ≤ 7).

• Poor lubrication: Check the quality and amount of lubricating oil, clean the bearings regularly, and replace the grease (high-temperature resistant grease is recommended).

• Improper bearing installation: Recalibrate the bearing assembly clearance.

• Long-term overload operation: Reduce the feed rate to avoid overload operation.

•Analyzer blade wear: Replace the blade or adjust the blade angle.

•Classifier failure: Check whether the classifier motor and transmission device are normal.

•Air duct blockage: Clean the accumulated powder in the pipeline to ensure smooth airflow.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery