Bentonite, an important non-metallic mineral, is widely used in metallurgy, foundry, petrochemicals, environmental protection, and other fields. Bentonite grinding production lines are the core equipment for efficient processing. This article will provide a detailed introduction to the bentonite grinding production line process, equipment selection, and industry applications, helping you fully understand this key production technology.

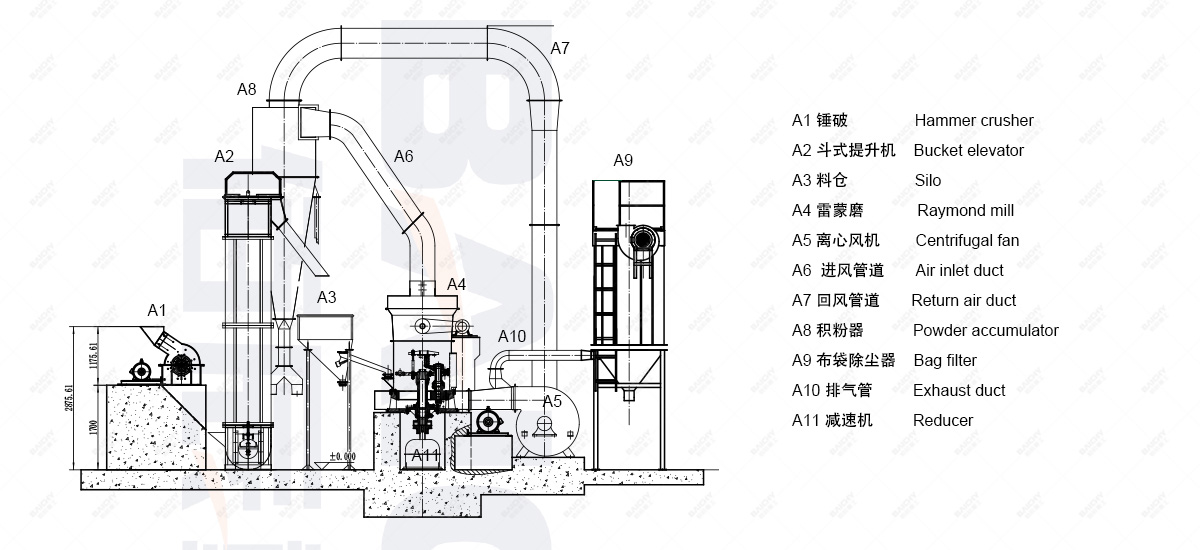

1. Raw Material Pretreatment: The raw bentonite ore undergoes pretreatment, including crushing and drying, to ensure it is suitable for subsequent grinding.

2. Grinding: Fine grinding is performed using equipment such as a Raymond mill, vertical mill, or ball mill to achieve the target fineness (typically 200-3000 mesh).

3. Classification and Collection: Qualified products are separated using a classifier, and the finished product is collected using a dust removal system.

4. Packaging and Storage: The finished bentonite powder is packaged, stored, or shipped directly to customers.

• Raymond mill: Suitable for small and medium-scale production, with low energy consumption and easy maintenance. • Vertical Mill: Suitable for large-scale, high-production needs, offering high grinding efficiency and environmental performance.

• Vertical Roller Mill: Suitable for processing ultrafine powders (3000 mesh and above), achieving high product purity.

The optimized design of a bentonite grinding line directly impacts product quality and production efficiency. Choosing the right equipment and process not only increases product value but also reduces energy consumption and costs. If you're planning a bentonite processing project, please contact us for professional solutions!

Advanced grinding technologies (such as Raymond mills, vertical mills, and air jet mills) are used, saving 30%-50% energy compared to traditional ball mills.

Adjustable fineness range of 200-3000 mesh, suitable for a variety of applications such as casting, chemical processing, and environmental protection.

Fully enclosed design and pulse dust removal ensure dust emissions ≤10mg/m³, meeting environmental requirements.

Key components are made of wear-resistant materials (such as high-chromium alloy grinding rollers) to extend equipment life.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery