Spiral classifier is a kind of equipment widely used in the classification of materials such as ore, sand, gravel, coal, etc. It separates materials according to particle size through the rotation of spiral blades. It is often used in mineral processing, building materials, the chemical industry and other industries.

• High-precision classification: suitable for 0.1-3mm particles, with a classification accuracy of 80-200 mesh.

• Stable and reliable: simple structure, low maintenance cost, and adaptable to harsh working conditions.

• Flexible selection: single/double spiral, high weir/sinking type and other models are available.

Spiral Classifier

Ore Classifying Equipment

High Weir Spiral Classifier

Classifier Model Parameters

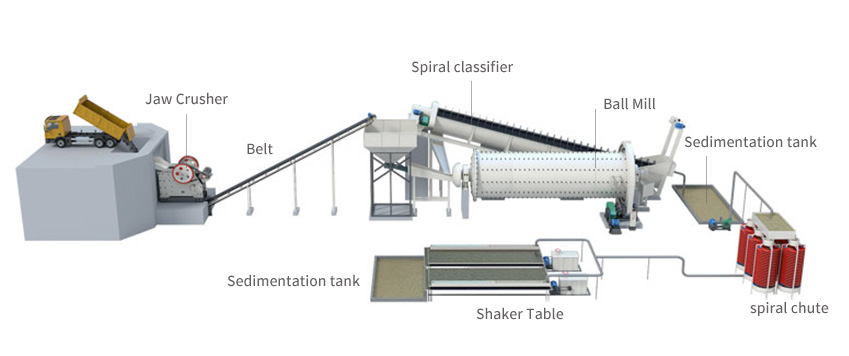

The spiral classifier pushes the coarse particles in the slurry upward through the rotation of spiral blades, and the fine particles are discharged with overflow to achieve particle size classification.

• Feeding: The slurry enters the classification tank from the feed port.

• Classification: The coarse particles settle and are pushed to the sand return port by the spiral blades; the fine particles are discharged with overflow.

• Discharge: Coarse sand is discharged from the bottom, and fine slurry flows out from the overflow weir.

• Applicable materials: gold ore, iron ore, quartz sand, coal slime, etc.

They are widely used to separate ore sands by forming a closed-circuit with the ball mill in concentrators, or gravity concentrators to classify ores and fine muds.

Applicable to 0.1-3 mm particles, the classification accuracy can reach 80-200 mesh, ensuring effective separation of fine particles and coarse particles.

Adopting spiral blade + reducer transmission, low failure rate and stable operation; the spiral blade adopts high manganese steel or rubber lining to extend the service life.

The processing capacity of a single device can reach 5-200 t/h, meeting the needs of small, medium, and large production lines.

Compared with cyclone separators, energy consumption is reduced by more than 30%, and long-term use can save on electricity bills.

The spiral classifier is mainly composed of a motor, a spiral blade, a spiral shaft, a tank body, a lifting mechanism, and a high wear-resistant liner.

The spiral classifier filters according to the gravity and falling speed of different particles. The fine particles floating in the water will be discharged from the upper part, and the coarse particles will sink to the bottom of the tank, and then the spiral blades will rotate the coarse particles to the feeding part to continue processing until reaching the ideal granularity.

| Model | Spiral diameter(mm) | Speed of Spiral(r/min) | Power (kw) | Slope (°) | Power(KW) | |

| Sand Return (t/h) | Overflow (t/h) | |||||

| FG500 | 500 | 8-12.5 | 6-11 | 32 | 12-18 | 1.1 |

| FG750 | 750 | 6-10 | 11-24 | 65 | 12-18 | 3 |

| FG1000 | 1000 | 5-8 | 25-45 | 110 | 12-18 | 5.5 |

| FG1200 | 1200 | 4-6 | 50-80 | 155 | 12-18 | 7.5 |

| FG1500 | 1500 | 4-6 | 70-115 | 235 | 12-18 | 7.5 |

| FG1800 | 1800 | 2.5-6 | 100-190 | 310 | 12-18 | 11 |

| FG2000 | 2000 | 3.6-5.5 | 160-230 | 400 | 12-18 | 15 |

https://www.baichychina.com/Beneficiation/spiral_classifier.html

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery