Track-mounted Mobile Impact Crusher is an intelligent mobile crushing equipment integrating crushing, screening and conveying, specially designed for mining, construction waste treatment, road construction and other scenarios. It is driven by a diesel engine and does not require an external power supply. It can operate in complex terrains, realize "on-site crushing and on-site utilization" of materials, and greatly reduce transportation costs.

1. Track-mounted movement·Flexible transfer: Full hydraulic crawler drive, suitable for rugged sites such as mountains, wetlands, and demolition sites, and there is no need to disassemble the equipment for transfer; remote control operation with one-button folding, rapid deployment in 30 minutes, and improved work efficiency.

2. Efficient impact crushing: equipped with a multi-cavity rotor impact crushing host, large crushing ratio, uniform finished product particle shape (needle-shaped <10%); processing capacity 50-300 tons/hour, can crush granite, concrete, construction waste and other materials.

3. Intelligent and environmentally friendly design: integrated PLC control system, real-time monitoring of equipment operation status, automatic fault alarm; low noise design + pulse dust removal system, in line with environmental emission standards.

Mining mobile crushing solution

Construction waste crushing equipment

Crawler mobile crusher price

Mobile impact crusher

• Construction waste recycling: On-site crushing of concrete and bricks to generate recycled aggregates.

• Mining: Replace traditional fixed production lines and reduce ore transportation costs.

• Emergency engineering: Quickly respond to temporary crushing needs such as road repairs and post-disaster reconstruction.

1. Does the Track-mounted mobile impact crusher require an external power supply?

No external power supply is required! Standard diesel engine, suitable for remote areas without power supply.

2. Is the equipment maintenance cost high?

Key components use international brands (such as SKF bearings), long life, and maintenance costs are reduced by 30%.

Track-mounted mobile impact crushers are recognized as experts in coarse crushing within the mining industry and serve as essential tools for construction waste recycling. These machines are specifically engineered to crush hard materials, including limestone and granite, and are also well-suited for applications such as construction waste recycling, road reconstruction, and other related projects.

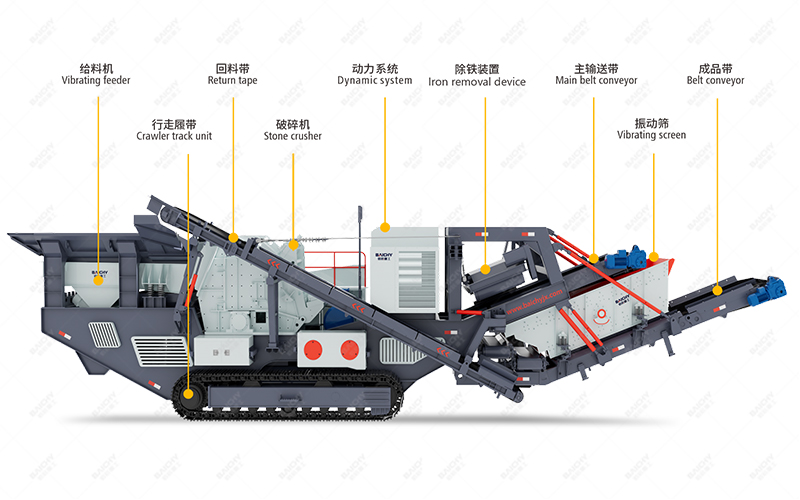

1. Feeding Stage: An excavator or loader feeds raw materials (e.g., ore, construction waste) into the vibrating feeder, which evenly distributes the material to the impact crusher.

2. Crushing Stage:

- Primary Crushing: The material is initially crushed through the high-speed rotation of the rotor and the action of the plate hammer.

- Secondary Crushing: The pre-crushed material rebounds upon hitting the impact plate, undergoing multiple impacts to ensure a uniform particle shape (with less than 15% needle-shaped particles).

3. Screening and Recirculation:

- The crushed material is screened by the vibrating screen. Qualified products are conveyed out via the belt conveyor, while oversized material is recirculated back to the impact crusher for reprocessing.

4. Finished Product Output:

- The discharge port can be adjusted according to specific requirements to produce various specifications of finished products, such as 0-5mm (for sand production), 5-20mm (for aggregate production), etc.

| Model | Feeder | Impact Crusher | Main Belt | Side Discharge Belt | Inspection Screen | Discharge Belt Under Screen | Transition Belt1 | Transition Belt2 | Screen Front Side Discharge Belt | Return Belt Conveyor | Capacity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| YMCI10S | GZD9538 | CI1110 | B1000x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 100-200t/h |

| YMC12S | GZD1135 | CI1213 | B1000x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 150-300t/h |

| YMCI12 | GZD1135 | CI1213 | B1000x10m | B500x3.8m | — | — | — | — | — | — | 150-300t/h |

| YMCI13S | GZD1235 | CI1313 | B1200x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.6m | 220-500t/h |

| YMCI13 | GZD1235 | CI1313 | B1200x10m | B500x3.8m | — | — | — | — | — | — | 220-500t/h |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery