Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

PE600×900 jaw crusher is a medium-sized coarse crushing equipmentwidely used in mining, building materials, roads, railways and other industries. Its feed port size is 600×900mm, the maximum feed particle size can reach 500mm, and the processing capacity is 90-180 t/h. It is suitable for primary crushing of various hard rocks such as granite, basalt, limestone, etc.

As a classic model of jaw crusher, PE600×900 has become the preferred equipment for medium-sized sand and gravel production lines and mining with its advantages of simple structure, stable operation and convenient maintenance.

• Efficient crushing, stable production capacity

• Sturdy and durable, low maintenance cost

• Strong adaptability and wide application

PE600×900 jaw crusher is usually used as primary crushing equipment, and cooperates with cone crusher, impact crusher, sand making machine, etc. to form a complete sand and gravel production line, which is suitable for medium-sized sand and gravel plants with a capacity of 90-180 t/h.

• Primary crushing: PE600×900 jaw crusher

• Secondary crushing: HP300 cone crusher / PF1214 impact crusher

• Sand making and shaping: VSI1145 sand making machine

• Screening equipment: 3YK2160 vibrating screen

| Model | PE600x900 |

|---|---|

| Feeder Opening Size(mm) | 600x900 |

| Max. Feeding Size(mm) | 500 |

| Outlet adjusting Size(mm) | 60-125 |

| Motor Power(kw) | 55 |

| Capacity(t/h) | 90-180 |

| Overall Dimension(mm) | 2500x2010x2350 |

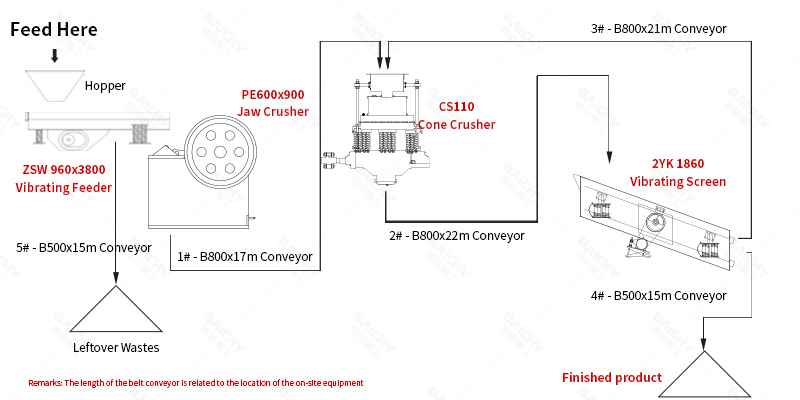

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW960x3800 | 1 |

| 3 | Jaw Crusher | PE600x900 | 1 |

| 4 | Cone Crusher | CS110 | 1 |

| 5 | Vibrating Screen | 2YK1860 | 1 |

| 6 | Belt conveyor | B650 | 4 |

80-120 t/h limestone crushing production line is an efficient and energy-saving sand and gravel aggregate production system, widely used in construction, highway, railway, and other industries. The production line is mainly composed of feeding equipment, crushing equipment, screening equipment, and conveying equipment, suitable for the crushing and processing of medium and low-hardness materials such as limestone and dolomite.

✔ Stable output: 80-120 tons per hour, meeting the needs of medium-sized sand and gravel plants

✔ Energy saving and environmental protection: optimize the crushing process, reduce energy consumption,n and dust pollution

✔ High degree of automation: PLC control system, reduces manual intervention

1. Coarse crushing stage: jaw crusher (recommended PE600×900, production capacity 90-180 tons/hour, matching production line requirements);

2. Medium and fine crushing stage: HP300 cone crusher or PF1214 impact crusher, strong wear resistance, suitable for long-term high-load operation, good finished product particle shape, suitable for pre-crushing of machine-made sand;

3. Screening equipment: 3YK1860 circular vibrating screen (multi-layer screen) 2-3 layers (can be graded into 0-5mm, 5-10mm, 10-20mm and other specifications);

1. Feeding stage: The limestone raw material is evenly fed into the PE600×900 jaw crusher for coarse crushing through a vibrating feeder.

2. Coarse crushing stage: The jaw crusher crushes the limestone to ≤150mm, and then enters the medium and fine crushing equipment through a belt conveyor.

3. Medium and fine crushing stage: The cone crusher/impact crusher performs secondary crushing, and the discharge particle size is ≤30-50mm.

4. Screening stage: The crushed material is graded by a circular vibrating screen, and the finished products that meet the requirements enter the finished product pile, and the oversized particles return to the crusher for re-crushing (closed-loop circulation).

5. Finished product output: The screened aggregate is transported to different silos through a belt conveyor to complete the production.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!