Powder classifier is a device used to separate powder particles according to particle size. It is widely used in chemical, pharmaceutical, food, new energy, metallurgy, building materials, and other industries. It can accurately control the particle size distribution of powder, improve product quality, and meet the refined production needs of different industries.

Core Functions

• Particle size classification: accurately separate mixed powders according to particle size (micrometer to millimeter).

• Improve uniformity: remove oversized or overfine particles to ensure product consistency.

• Optimize process: suitable for the production of ultrafine powders (such as nanomaterials) and high-purity materials.

Airflow Classifier

Powder Classifier

Ultrafine Powder Classification

Ultrafine Powder Classifier

Chemical: Classification of fillers such as calcium carbonate, graphite, and titanium dioxide.

New energy: Particle size control of positive and negative electrode materials of lithium batteries and photovoltaic materials.

Pharmaceutical: Homogenization of drug particles to improve solubility.

Food: Fine classification of milk powder, starch, and seasonings.

The selection of powder classifiers needs to comprehensively consider factors such as material properties (hardness, humidity, viscosity), target particle size, and output requirements. Modern equipment can also be combined with intelligent control systems to achieve automated production and improve classification accuracy and efficiency.

Particle size distribution is more reasonable, final product quality has been improved significantly.

The airflow classifier can achieve accurate separation of 0.1~100μm, meeting the stringent requirements of ultrafine powders (such as lithium battery materials and pharmaceutical powders).

Supports 24-hour continuous production, with a processing capacity ranging from a few kilograms/hour to tens of tons/hour, suitable for large-scale industrial needs.

Applicable to chemical, pharmaceutical, food, new energy, metallurgy and other fields, such as titanium dioxide, drug particles, milk powder, lithium battery materials, etc.

Avoid blockage and reduce maintenance costs, especially suitable for ultrafine powders; optimize energy consumption through PLC or frequency conversion technology, saving 20%~30% energy compared to traditional screening machines.

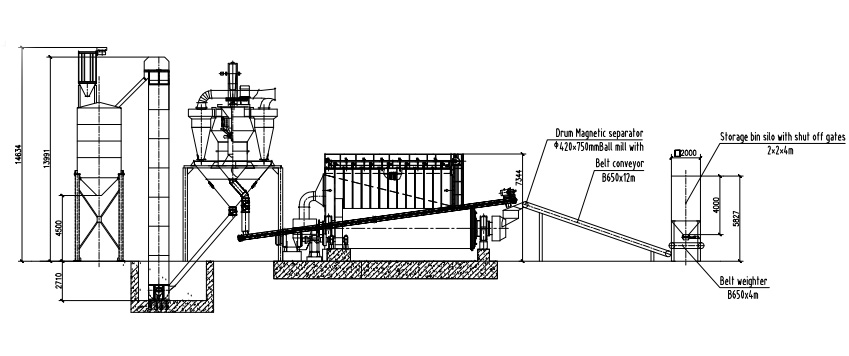

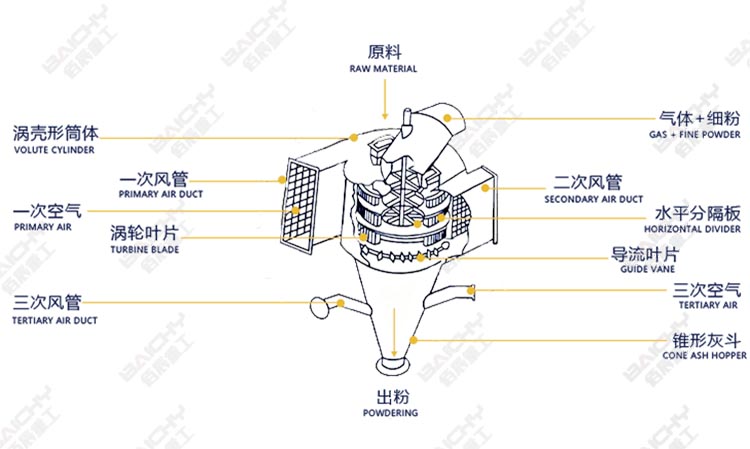

The upper part of the powder classifier is a cylindrical grading chamber, and the lower part is a conical discharge port. Usually, two or more powder classifiers form a powder classifying system.

The ground powder is fed from the upper part of the powder classifier, and after being fully dispersed by the spreading plate and the baffle plate, the coarse powder is discharged through the coarse powder pipe, and the fine powder that meets the requirements enters the high-efficiency and low-resistance cyclone separator with the circulating air and slides Into the fine powder collection cone to become a finished product.

| Model | S400 | S500 | S600 | S700 | S900 | S1000 | S1100 | S1200 | |

| Matched mill (m) | Φ1.5 | Φ1.83 | Φ2.2 | Φ2.4 | Φ3.0 | ||||

| Motor Blower | Model | YCTL200-4A | YCTL200-4B | YCTL200-4A | YCTL200-4B | YCTL200-4B | YCTL200-4A | YCTL200-4A | YCTL200-4B |

| Rotating speed(r/min) | 125-1250 | 132-1320 | 440-1340 | 440-1340 | 600-1340 | ||||

| Power (KW) | 7.5 | 11 | 15 | 18.5 | 37 | 55 | 75 | 90 | |

| Model | SCF-12NO.8C | SCF-12NO.8C | SCF-12NO.10C | SCF-12NO.12C | SCF-12NO.12C | SCF-12NO.16B | SCF-12NO.16D | SCF-12NO.12C | |

| Volume | 24216 | 30900 | 37960 | 58200 | 119332 | 168000 | 192000 | 211000 | |

| Air pressure | 2.18 | 2.43 | 2.34 | 2.07 | 2.26 | 2.70 | 2.70 | 2.60 | |

| Rotating speed(r/min) | 1500 | 1600 | 1200 | 1000 | 800 | 960 | 960 | 710 | |

| Model | Y180M-2 | Y200L1-2 | Y225S-4 | Y225M-4 | Y335M1-8 | Y335M1-6 | Y335M3-6 | Y335L-8 | |

| Power (KW) | 22 | 30 | 37 | 55 | 132 | 160 | 200 | 220 | |

| Rotating speed of shaft (r/min) | 190-380 | 190-380 | 150-350 | 150-350 | 140-350 | 100-300 | |||

https://www.baichychina.com/Powder/classifier.html

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery