C Series Jaw Crusher is a high-performance crushing equipment designed for coarse crushing conditions such as mining, sand and gravel aggregates, and construction waste treatment. Made of optimized cavity structure and high-strength materials, it can handle various hard rocks (such as granite, basalt, iron ore, etc.) with a compressive strength of ≤320MPa. It has a large crushing ratio and stable output, making it an ideal choice for the coarse crushing stage.

1. Efficient crushing: deep cavity design + large stroke, 50-1400 tons per hour (depending on the specific model), improving the efficiency of the entire production line.

2. Ultra-long life: manganese steel jaw plate + heavy-duty bearing, wear resistance increased by 30%, reducing maintenance costs.

3. Intelligent adaptation: optional hydraulic adjustment device, quick adjustment of discharge particle size (range 40-300mm).

4. Energy saving and environmental protection: motor power optimization, energy consumption reduced by 15%, in line with green mine standards.

Model For Mobile Crusher Plant : CJ96 | CJ106 | CJ116 | CJ120

Mining crushing equipment

Primary crusher manufacturers

High capacity jaw crusher

Rock crusher

1. Strong structure: integral cast steel frame + modular design, strong impact resistance, easy installation.

2. Simple maintenance: hydraulic lubrication system + flip guard plate, maintenance time is shortened by 50%.

3. Widely applicable: can be used in iron ore, gold mine, limestone, concrete recycling and other fields.

• Small and medium-sized production lines: C80/C100, suitable for projects with an output of less than 200 tons per hour.

• Large mines: C150 and above models, matching high production needs.

C series jaw crusher is suitable for crushing a variety of materials, including river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc. These materials have different hardness and characteristics, but a C series jaw crusher can effectively crush them.

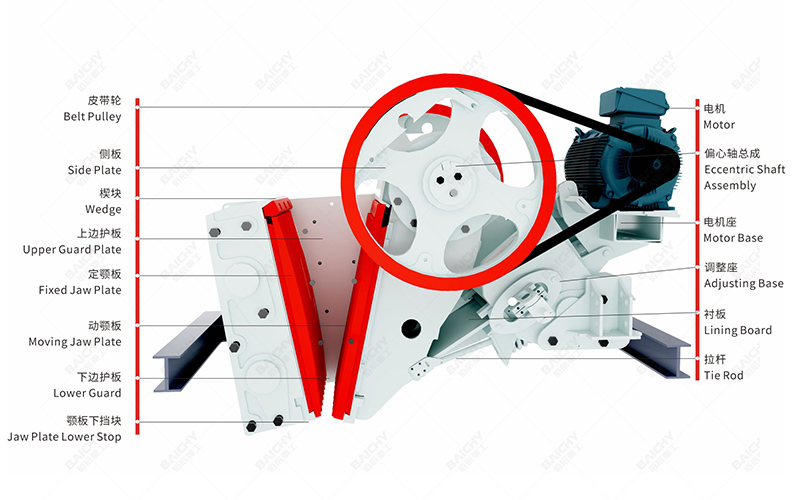

• Feeding stage: The material is put into the crushing chamber from the top feed port and falls between the fixed jaw and the movable jaw.

• First extrusion: The movable jaw approaches the fixed jaw under the drive of the eccentric shaft, and the material is squeezed and split between the two jaw plates, and the large pieces of material are initially crushed.

• Crushing stage: The movable jaw continues to move, the space of the crushing chamber gradually becomes smaller, and the material is repeatedly squeezed and ground until it reaches a dischargeable particle size.

• Discharging stage: When the movable jaw retreats, the crushed material is discharged from the bottom discharge port under the action of gravity; the material that does not meet the standard continues to remain in the crushing chamber for secondary crushing.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting range(mm) |

Centrifugal Shaft Speed(rmp) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| Model For Fixed Crushing Plant | |||||||

|---|---|---|---|---|---|---|---|

| C80 | 500×750 | 400 | 40-150 | 290 | 50-160 | 55 | 2748x1840x1701 |

| C90 | 610×910 | 500 | 60-180 | 260 | 60-180 | 75 | 3170x1995x1936 |

| C100 | 760×1060 | 600 | 70-200 | 260 | 150-300 | 110 | 4127x2354x2350 |

| C110 | 850×1100 | 700 | 70-200 | 230 | 200-400 | 132 | 4350x2700x2800 |

| C125 | 950×1250 | 800 | 100-250 | 220 | 300-800 | 160 | 4450x2764x2910 |

| C140 | 1070×1400 | 900 | 125-270 | 220 | 400-900 | 200 | 4830x3330x4000 |

| C160 | 1200×1600 | 1000 | 150-300 | 220 | 500-1200 | 250 | 5340x3540x3350 |

| C200 | 1500×2000 | 1200 | 175-300 | 200 | 800-1400 | 400 | 6500x3990x4260 |

| Model For Mobile Crusher Plant | |||||||

| CJ96 | 580×930 | 480 | 60-170 | 290 | 60-160 | 75 | 3000x1900x2100 |

| CJ106 | 700×1060 | 580 | 70-180 | 280 | 150-300 | 110 | 3310x2490x2470 |

| CJ116 | 760×1150 | 680 | 70-190 | 260 | 200-400 | 160 | 3600x2380x2750 |

| CJ120 | 870×1200 | 780 | 70-200 | 230 | 400-500 | 185 | 3880x2700x3000 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery