Dolomite (chemical formula: CaMg(CO₃)₂) is an important non-metallic mineral widely used in building materials, chemicals, metallurgy, environmental protection, and other fields.

• Building materials: cement, concrete admixtures

• Chemical industry: glass, ceramics, rubber fillers

• Metallurgical industry: steelmaking flux, magnesium metal extraction

• Environmental protection: flue gas desulfurization, wastewater treatment

Because different industries have different requirements for dolomite powder fineness (mesh size) and purity, specialized dolomite grinding lines are required for refined processing.

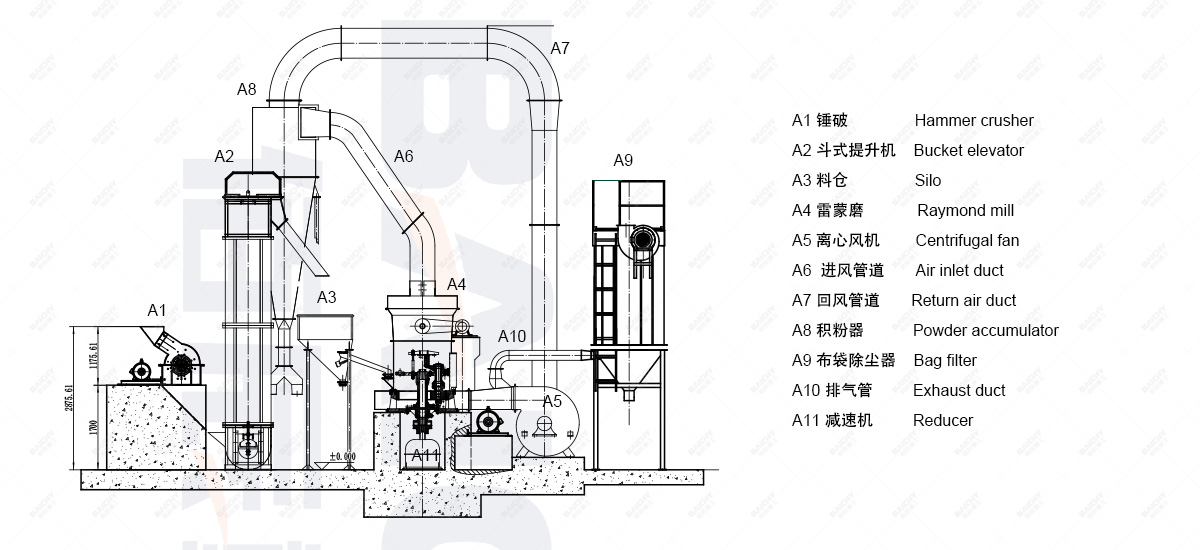

1. Crushing: Ore → Jaw Crusher (Coarse Crushing) → Hammer Crusher (Fine Crushing)

2. Grinding: Crushed Material → Grinding Mill (Raymond Mill/Vertical Mill) → Classifying Screen → Qualified Powder

3. Collection and Packaging: Powder Collection by Pulse Dust Collector → Automatic Packaging Machine → Finished Product Storage

• 80-200 Mesh (Building Material Grade): Raymond Mill

• 325-2500 Mesh (High-Purity Ultrafine Powder): Requires Vertical Mill + Classifying System

Dolomite grinding lines are key equipment for increasing the added value of resources. Choosing an efficient, energy-saving, and environmentally friendly grinding solution will give your products a competitive edge in the market.

1. The finished product has uniform particle size and high output:

After being processed by the dolomite grinding production line, the finished dolomite has a uniform particle size and can meet the particle size distribution requirements of different industries.

The production line adopts efficient grinding equipment, such as YGM grinding mill, etc., which ensures high output and can meet the needs of large-scale production.

2. The fineness of the finished product is adjustable:

The dolomite grinding production line can adjust the fineness of the finished product according to market demand to meet the requirements of different industries for dolomite powder fineness.

By adjusting the parameters and configuration of the grinding equipment, the fineness of the finished product can be easily adjusted and controlled.

3. Mature technology and stable operation:

The dolomite grinding production line adopts mature grinding technology and technology. After years of development and improvement, a relatively complete production line configuration and process flow have been formed.

The equipment operates stably and reliably, and can continuously and stably produce high-quality dolomite powder products.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery