Escape the constraints of fixed sites and high relocation costs! Our mobile, high-efficiency crushing solutions, with their innovative integrated design, perfectly combine superior crushing performance with unparalleled mobility.

• Rapid Deployment, Hassle-Free Relocation: The equipment features a built-in high-strength chassis, integrating feeding, crushing, and conveying systems, truly achieving production upon arrival. Whether for urban construction waste processing or remote mountain mining, it can be quickly put into operation, greatly improving your return on investment.

• Robust Performance, Unstoppable: Powered by a robust core engine (45-160 kW motor), the equipment possesses immense crushing force. Whether it's incredibly hard granite and basalt, or complex construction waste, it can easily transform it into high-quality, uniformly shaped finished aggregate at a rate of 40-400 tons/hour.

• Wide Applicability, Multi-Functional: From feeding large raw materials ≤680mm to meeting the core crushing needs of small stone quarries, medium-sized engineering projects, and even large mines, this equipment can handle it all exceptionally well. It is your reliable partner for expanding persified businesses.

• High Efficiency and Mobility: Integrated design with its own chassis for easy relocation.

• Powerful Capacity: Up to 400t/h processing capacity, easily handling hard rock and waste materials.

• High-Quality Finished Products: Produces aggregates with uniform particle shape and high commercial value.

• Wise Investment: Versatile machine adaptable to various working conditions, maximizing equipment utilization.

Click to inquire and get specific capacity and pricing plans for your current project!

Mobile Jaw Crusher in Kyrgyzstan

Mobile Jaw Crusher

Mobile Crushing Plant In Guangdong

Mobile PE Jaw Crusher

→ Our Solution: Integrated design with a built-in heavy-duty chassis. Easy to move like a trailer, eliminating complex disassembly and reassembly procedures, ensuring your equipment always follows the most profitable projects.

→ Our Solution: Boasting a powerful 160kW motor and a special crushing structure, with a feed size of ≤680mm, it consistently produces high-quality finished products, whether from hard rock or recycled aggregate, with a processing capacity of 40-400 t/h.

→ Our Solution: Advanced crushing technology ensures excellent output particle shape and reasonable gradation, directly enhancing your product's market competitiveness and profit margin.

Click to inquire and get specific capacity and pricing plans for your current project!

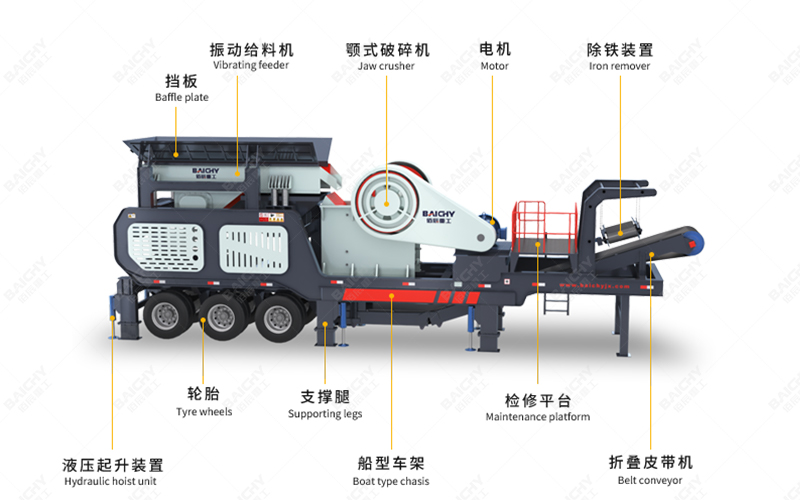

The modular mobile jaw crusher is equipped with high-strength alloy jaw plate (hydraulic adjustment of discharge particle size), pre-screening vibrating feeding system, diesel/electric dual power drive, all-terrain crawler/tire chassis, PLC intelligent control system (supports remote monitoring) and environmental protection device (noise ≤75dB+ spray dust reduction). It has the characteristics of efficient crushing, flexible transfer, intelligent operation, etc., and is suitable for processing hard materials such as mines and construction waste.

1. Feeding: excavator feeding → automatic speed regulation of vibrating feeder

2. Crushing: jaw plate extrusion → adjustable discharge particle size (example: roadbed material 50mm)

3. Discharging: belt conveyor pile (0-20mm finished product) → direct loading or entering the next process

| Model (Primary Stage) | YDPZ57-8530 | YDPZ80-8530 | YDPZ69-9638 | YDPZ96-9638 | YDPZ75-1142 | YDPZ106-1142 | YDPZ116-1242 | YDPZ116-1242 |

| Vibrating Feeder | ZSW8530 | ZSW8530 | ZSW9638 | ZSW9638 | ZSW1142 | ZSW1142 | ZSW1142 | ZSW1142 |

| Jaw Crusher | PE500×750 | C80 | PE600×900 | C96 | PE750×1060 | CJ106 | CJ116 | CJ116 |

| Feeding Size(mm) | ≤425 | ≤400 | ≤500 | ≤480 | ≤630 | ≤580 | ≤680 | ≤680 |

| Belt Conveyor | B650 | B650 | B800 | B800 | B1000 | B1000 | B1000 | B1000 |

| Motor Power(kw) | 7.5+45+4 | 7.5+55+4 | 11+55+4 | 11+90+4 | 15+110+4 | 15+110+4 | 15+132+4 | 15+132+4 |

| Capacity (t/h) | 40-130 | 50-160 | 90-180 | 60-160 | 110-380 | 150-300 | 200-400 | 200-400 |

| Overall Size(mm) | 10000x2300x4020 | 10000x2300x4020 | 11500x2300x4120 | 11600x2250x3710 | 12500x2550x4570 | 12850x2280x3950 | 13000x2550x4150 | 13000x2550x4150 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery