A shaking table, also known as a "separation plate," "mineral processing shaking table," or "gravity shaking table," is a gravity separation device that separates mineral particles based on differences in density and size.

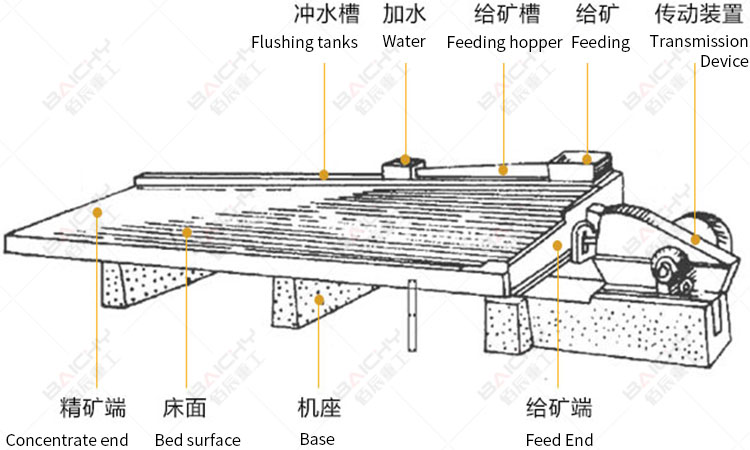

Its core feature is the use of an inclined bed surface with specific grooves. Under the combined action of asymmetrical reciprocating motion and the scouring effect of lateral water flow, different particles in the fed slurry exhibit different movement trajectories, thus forming fan-shaped zones on the bed surface and efficiently separating concentrate, middlings, and tailings.

A shaking table is a typical gravity separation device. It does not rely on chemical reactions but utilizes the differences in physical properties between the minerals to be separated and the gangue minerals—primarily density, and secondarily particle size and shape. Denser, smaller particles tend to move in one direction, while less dense, larger particles move in the other.

Shaking Table

Mineral Processing Equipment

Gravity Separation

Shaking Table Working Principle

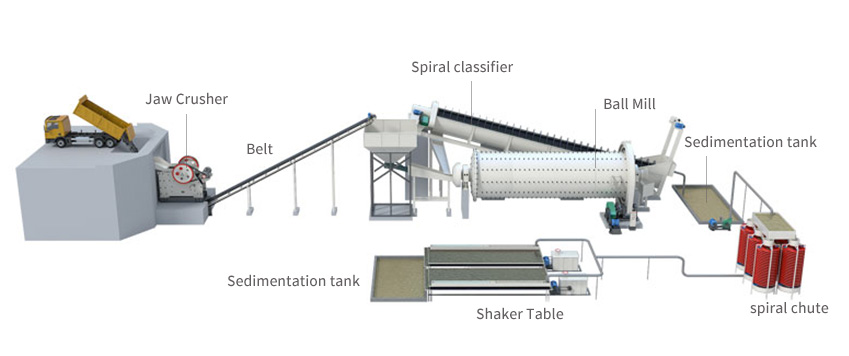

As a cleaning unit (core role): This is the shaking table's most important role. It is typically located in the later stages of the mineral processing flow, receiving the rough concentrate from roughing equipment such as jigs, spiral concentrators, and centrifugal concentrators. The shaking table's task is to "fine-refine" the rough concentrate, obtaining qualified high-grade concentrate that can be directly sold.

• Flow Example: Raw ore → Crushing → Grinding → Spiral sluice/jig (roughing) → Shaking table (cleaning) → Concentrate.

As a scavenging unit: Sometimes it is also used to process tailings from other gravity separation equipment, recovering valuable minerals, reducing metal loss, and improving the overall recovery rate.

Strong resistance to harsh environment.

The enrichment ratio (the ratio of concentrate grade to raw ore grade) is higher than many other mineral processing methods, up to more than 100 times.

The shaking table is effective in handling mineral materials and can obtain the qualified concentrate and separate the discarded tailings after one separation.

The upper limit of the separation particle size is 3mm, the lower limit can reach 0.4mm, and it is mostly used for separating materials below 1mm.

Compared with the traditional process, the shaking table has low energy, easy management, and the best price.

1. Headstock (Transmission Mechanism): This is the "heart" of the shaking table, responsible for generating and transmitting the asymmetric reciprocating motion required by the table surface.

2. Table Surface: This is the "stage" for the sorting operation, the core component that directly contacts the minerals.

The shaking table utilizes the combined action of the asymmetric reciprocating motion of the table surface and the lateral water flow to stratify mineral particles in the slurry according to density and particle size. Heavy minerals settle to the bottom and are propelled towards the concentrate end by the friction of the table surface; light minerals are washed towards the tailings end by the water flow. Ultimately, different minerals are separated into fan-shaped zones on the table surface, thus achieving precise separation.

| Name | bed surface for coarse sand | bed surface for fine sand | bed surface for slurry | |

| Bed | Length(mm) | 4450 | 4450 | 4450 |

| dimension | transmission end width(mm) | 1855 | 1855 | 1855 |

| concentrate ore width(mm) | 1546 | 1546 | 1546 | |

| Max Feeding Size(mm) | 2 | 0.5 | 0.15 | |

| Feeding volume(t/h) | 30-60 | 10-20 | 15-25 | |

| Feeding density(%) | 25-30 | 20-25 | 15-25 | |

| stroke(mm) | 16-22 | 11-16 | 8-16 | |

| Frequency( t/s) | 45-48 | 48-53 | 50-57 | |

| Cross Slope of Surface | 2.5°-4.5° | 1.5°-3.5° | 1°-2° | |

| mineral dressing area(㎡) | 7.6 | 7.6 | 7.6 | |

| Shape of bed surface | Rectangle | indention | Triangle | |

| Motor Power(KW) | 1.1 | 1.1 | 1.1 | |

| Driving type | Eccentric link structure | |||

| Remarks: Any change of technical parameters, there is no further notice. | ||||

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery