Calcite (CaCO₃) is an important industrial mineral raw material, widely used in plastics, papermaking, coatings, rubber, building materials and other industries. To process it into powders of varying fineness (such as 325 mesh, 800 mesh, 1250 mesh, and even 3000 mesh), a professional calcite grinding production line is required.

Ore → Jaw Crusher (Coarse Crushing) → Hammer Crusher (Fine Crushing) → Particles ≤30mm

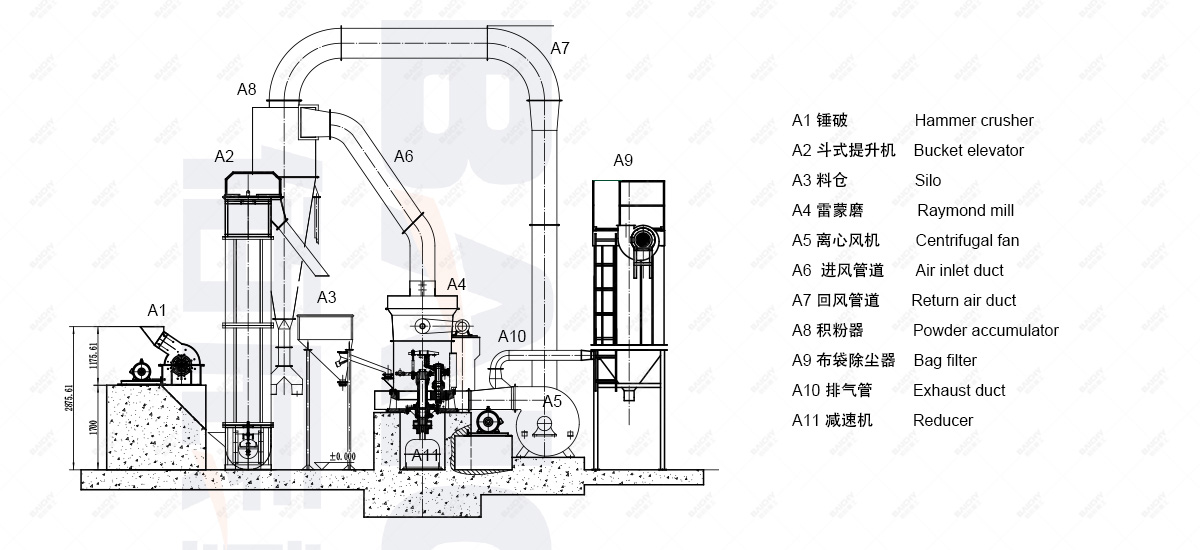

• Coarse Powder Processing (80-325 mesh): Raymond Mill Direct Grinding → Cyclone Collection → Packaging

• Ultrafine Powder Processing (800-3000 mesh): Vertical Mill/Ball Mill → Classifier → Secondary Grinding → Dust Collection

• Qualified Powder → Storage Silo → Automatic Packaging Machine → Ton Bags/25kg Small Bags

• Environmental Requirements: The entire production line must be equipped with a pulse dust removal system to ensure dust emissions meet standards.

The configuration of the calcite grinding production line should be customized based on factors such as raw material characteristics, production capacity requirements, and finished product fineness. Raymond mills are suitable for coarse powder processing, while vertical mills and ball mills are more suitable for ultrafine powder production. Before investing, be sure to compare multiple manufacturers and examine the equipment performance and after-sales service to ensure the long-term stable operation of the production line.

• The production line has been optimized and efficiently configured to produce high-quality calcite fine powder continuously and stably.

• The use of advanced crushing and grinding technology greatly improves processing efficiency and production capacity.

• Through a precise grading system, calcite fine powder with uniform particle size distribution and up to standard fineness can be produced.

• High-quality fine powder is widely used in plastics, rubber, paint, coatings, papermaking and other industries, and has broad application prospects.

• The production line is equipped with advanced electrical control systems and automated operating equipment, which reduces manual intervention and reduces operating difficulty.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery