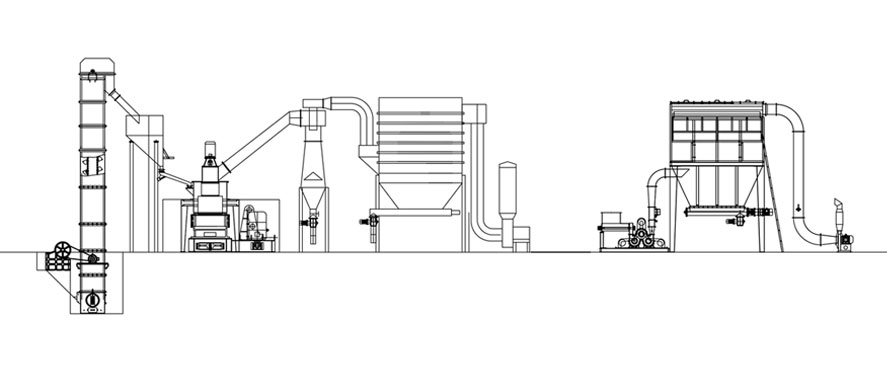

DMC pulse dust collector, namely DMC pulse bag dust collector, is a highly efficient air pollution control equipment, that is widely used in many industries such as building materials, metallurgy, mining, coal, and non-metallic mineral ultrafine powder processing. DMC pulse dust collector plays an important role in the field of air pollution control with its high efficiency, reliability, and strong adaptability.

DMC pulse dust collector is widely used in dust control in cement, steel, chemical, power, and other industries. In the cement industry, it can be used for dust control of equipment such as mills and packaging machines; in the steel industry, it can be used for dust collection in production lines such as blast furnaces and converters; in the power industry, it can be used for dust removal of boilers, flue gas desulfurization and other equipment.

DMC pulse dust collector adopts advanced pulse jet cleaning technology, and the dust removal efficiency can reach 99.99%, ensuring that the emission concentration meets the national environmental protection standards.

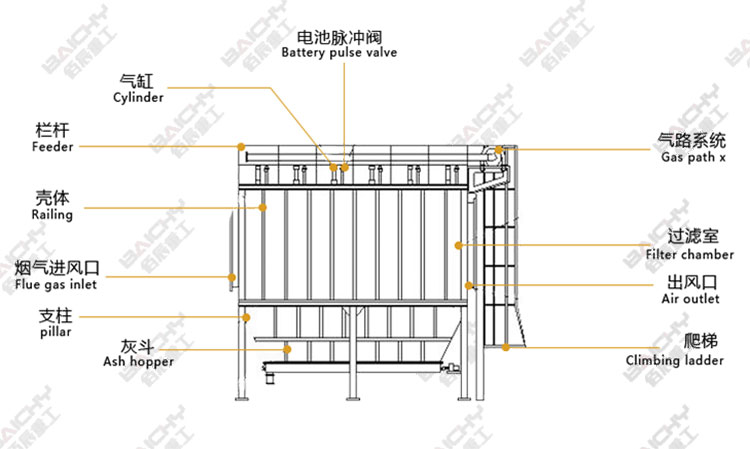

The equipment is small in size, light in weight, simple and compact in structure, and easy to install and maintain.

The external filter structure makes the replacement and cleaning of the filter bag more convenient and quick.

Adopting a PLC programmable control system, it has functions such as automatic control, fault diagnosis, and remote monitoring, and can achieve fully automatic operation.

Under the effect of the air fan, airflow with dust is sucked into the dust collecting chamber from the bottom or one side. Those big dust particles will go downwards because of the decreasing speed of the airflow. While, those fine dust particles, will be stopped at the outside layer of the filter bag. When compressed air blows reverse back the filter bag, the fine particles will break away from the bag and go downwards with the big particles. Finally, dust particles will be discharged outside and the purified air will be discharged upon the upper side of the cleaning chamber. Finally, it plays a role of collecting dust, and air pollution prevention purpose.

| Model | Total filter area (m2) | Filtering wind speed (m/s) | Input air (m³/h) | No. of filter bag (pc) | Specification of filter bag (mm) | Air consumption (m³/h) | Density of inlet (g/m³) | Density of outlet (mg/m³) |

| DMC-32 | 24-32 | 1.04-1.67 | 1500-2400 | 32 | ∅120x2000/∅130x2500 | 0.032 | 200 | 50 |

| DMC-48 | 36-48 | 1.15-1.62 | 2500-3500 | 48 | ∅120x2000/∅130x2500 | 0.048 | ||

| DMC-64 | 48-64 | 1.21-1.74 | 3500-5000 | 64 | ∅120x2000/∅130x2500 | 0.064 | ||

| DMC-80 | 60-80 | 1.25-1.67 | 4500-6000 | 80 | ∅120x2000/∅130x2500 | 0.08 | ||

| DMC-96 | 72-96 | 1.27-1.62 | 5500-7000 | 96 | ∅120x2000/∅130x2500 | 0.096 | ||

| DMC-112 | 84-112 | 1.28-1.68 | 6500-8500 | 112 | ∅120x2000/∅130x2500 | 0.11 | ||

| DMC-128 | 90-128 | 1.31-1.76 | 7500-9500 | 128 | ∅120x2000/∅130x2500 | 0.12 | ||

| DMC-168 | 126-168 | 2.54-2.87 | 9500-10500 | 168 | ∅120x2000/∅130x2500 | 0.168 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery