Vibrating feeders are key upstream equipment in industrial processes such as sand and gravel aggregate production lines, mining and mineral processing, and building materials processing.

A vibrating feeder is a device that uses a vibrating motor or electromagnetic exciter to generate directional vibration force, driving the trough to perform periodic reciprocating vibration, thereby achieving uniform, continuous, and quantitative material conveying. This equipment has a simple structure, reliable operation, and convenient adjustment, making it an indispensable pre-processing feeding device in crushing and screening production lines.

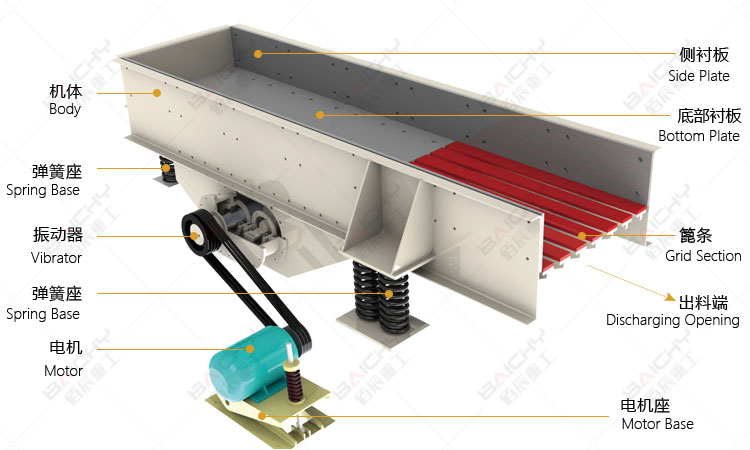

• Trough: Carries the material, made of wear-resistant steel plate, and can be lined with wear plates according to material characteristics.

• Vibrating Motor: Provides the excitation source; two motors rotate synchronously in opposite directions to generate directional vibration force.

• Damping Springs: Support the trough, absorb vibration, and reduce the dynamic load transmitted to the foundation.

• Support/Suspension Device: Fixes the equipment; can be installed in a seated or suspended manner.

• Control Cabinet (optional): Integrates a frequency converter to achieve stepless adjustment of feeding volume and remote control.

Ore Conveying Equipment

Mining Vibrating Feeder

Vibrating Feeder Manufacturer

Mining Feeding Equipment

1. Stable operation and uniform feeding: Uses dual vibrating motors for synchronous drive, ensuring stable amplitude and continuous, uniform material conveying, preventing blockages or interruptions.

2. Energy-efficient and low noise: Driven by vibrating motors, energy consumption is reduced by more than 30% compared to traditional feeding equipment, resulting in low operating noise and a friendly working environment.

3. Simple maintenance and long service life: The trough is made of wear-resistant steel plate, the structure is robust, key components are sealed and dustproof, daily maintenance is simple, and the service life is long.

4. Convenient adjustment and strong adaptability: By adjusting the motor excitation force or using frequency control, the feeding volume can be easily adjusted to adapt to different materials and process requirements.

The vibrating feeder is widely used to match the crushing and sieving equipment in many industries including stone crushing plants, metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

Two vibrating motors generate directional excitation forces, driving the feeding trough to perform periodic linear reciprocating vibrations along an inclined direction.

When the vertical component of the trough's vibration acceleration is greater than the acceleration due to gravity, the material in the trough is continuously thrown up.

The material moves forward in a jumping motion, achieving uniform and continuous conveying.

Controlled by adjusting the excitation force of the motors.

Alternatively, stepless speed regulation can be achieved by installing a frequency converter.

| Model | Trough size(mm) |

Max feed size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall dimension L*W*H(mm) |

| ZSW650×2500 | 650×2500 | 560 | 50-90 | 1.1×2 | 2570×890×1000 |

| ZSW850×3000 | 850×3000 | 780 | 80-120 | 7.5 | 3110×1800×1100 |

| ZSW960×3800 | 960×3800 | 820 | 120-210 | 11 | 3850×1950×1100 |

| ZSW1100×4200 | 1100×4200 | 1000 | 200-430 | 15 | 4400×2050×1200 |

| ZSW1100×4900 | 1100×4900 | 1000 | 280-500 | 18.5 | 5200×2050×1200 |

| ZSW1300×4900 | 1300×4900 | 1100 | 450-600 | 22 | 5200×2350×1400 |

| ZSW1300×6000 | 1300×6000 | 1100 | 450-680 | 22 | 6300×2300×1400 |

| ZSW1500×6000 | 1500×6000 | 1280 | 550-1200 | 30 | 6300×2550×1400 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery