This high-capacity impact crusher expertly crushes, shapes, and makes sand in one machine. It produces cubic-shaped aggregates and well-graded sand, ideal for premium sand and gravel production.

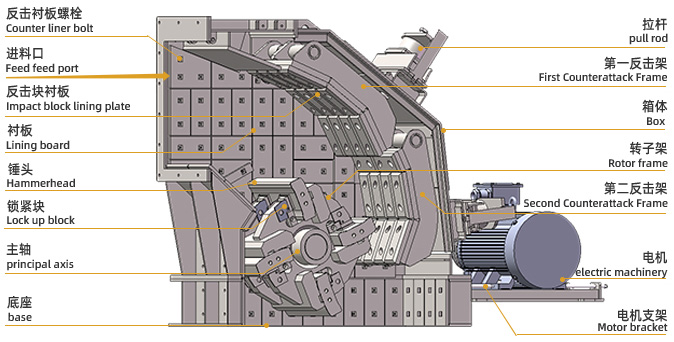

The CI series impact crusher (also known as a vertical shaft impact crusher) utilizes advanced stone-on-stone and stone-on-iron crushing principles. A high-speed rotating impeller accelerates and throws the material, causing it to collide and break against the material lining or impact blocks in the crushing chamber. This equipment combines crushing, shaping, and sand making functions, producing cubic-shaped sand and aggregate with a reasonable gradation, making it an ideal choice for high-quality sand and aggregate production.

• River pebbles, granite, basalt, limestone, quartz stone, iron ore, etc.

• Recycling and crushing of construction waste

• Mine tailings treatment

• Manufactured sand production and stone shaping

• Aggregate production for high-grade highways, railways, water conservancy projects, and construction industries

• Secondary and tertiary crushing processes in mining

• Sand and aggregate production for concrete mixing plants

CI series Impact crusher

Impact crusher

Impact Crusher With Various Models

Stone Crushing Machine - Impact Crusher

1. High efficiency and energy saving, outstanding output: The unique crushing chamber design and high linear speed significantly improve crushing efficiency and reduce energy consumption per unit.

2. Excellent product particle shape: The combination of stone-on-stone and stone-on-iron principles results in cubic-shaped finished material particles with low needle-like and flaky content, especially suitable for high-standard aggregate requirements.

3. Low wear of wear parts and long service life: The core wear-resistant components are made of high-chromium alloy or ceramic composite materials, providing strong wear resistance. The optimized flow channel design reduces friction between the material and the surrounding protective plates, resulting in low maintenance costs.

4. Simple installation and maintenance, stable operation: The compact structural design allows for flexible installation. The hydraulic opening device makes inspection and maintenance of the rotor and wear parts more convenient and faster. The equipment operates with low vibration and low noise.

The CI series large-mouth impact crusher handles materials of varying hardness, from limestone and granite to construction waste. Its wide applicability makes it a preferred choice across industries like mining, cement, and construction, as well as for infrastructure projects.

The working principle of the CI series impact crusher follows a highly efficient process of centrifugal acceleration → material impact → finished product discharge, as follows:

1. Feeding: Material enters from the top and falls into the center of the high-speed rotating impeller.

2. Acceleration: Under the action of centrifugal force, the impeller throws the material out of the flow channel at high speed.

3. Impact Crushing: The ejected material first collides with the falling material (stone-on-stone impact), achieving initial crushing.

4. Impact Shaping: Subsequently, the material impacts the material lining or impact blocks formed in the cavity (stone-on-metal impact), further crushing and optimizing the particle shape.

5. Classification and Discharge: Qualified material is discharged from the bottom, while unqualified particles continue to be crushed in the cavity.

| Model | Max. Feeding Size (mm) | Motor Power (kw) | Capacity (t/h) | Overall Size |

| For Secondary Or Tertiary Crushing Stage | ||||

| CI1110 | 500 | 160 | 110-260 | 2826×2087×2285 |

| CI1213 | 550 | 200 | 145-350 | 2903×2530×2411 |

| CI1316 | 600 | 250 | 200-450 | 3320×2770×2535 |

| CI1521 | 400 | 2×(200-250) | 335-760 | 3450×3620×2770 |

| For Primary Crushing Stage | ||||

| CI1313 | 600 | 200 | 100-480 | 2972×2560×2937 |

| CI1415 | 600 | 250 | 120-600 | 2985×2790×3068 |

| CI1620 | 800 | 2×(200-250) | 220-900 | 4261×3480×3780 |

| CI2023 | 800 | 2×500 | 400-2000 | 5151×4424×4712 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery