Why does the granite crushing production line need special configuration?

Granite is one of the hardest building stones, with a Mohs hardness of 6-7, which places extremely high demands on crushing equipment. Unlike ordinary limestone or basalt, the high hardness and high silicon content of granite will lead to increased equipment wear and energy consumption. This article will deeply analyze the unique configuration logic of the granite crushing production line and share the practical experience of the whole process from equipment selection to installation and commissioning.

1. Special requirements of granite characteristics on production line configuration

1.1 Challenges brought by physical characteristics

• High hardness: The equipment is easy to wear, and a crushing chamber made of special alloy material needs to be selected

• High silicon content: SiO₂ content exceeds 65%, which aggravates the wear of plate hammer and liner

• Irregular crystal structure: Needle-like particles are easily produced after crushing, affecting the quality of finished products

1.2 Neglected economic accounts

Most investors only pay attention to the equipment procurement cost, but ignore:

• Wear-resistant parts replacement frequency: The wear and tear of granite production line is 3-5 times that of limestone production line

• Energy consumption difference: Energy consumption is 30-45% higher at the same output

• Downtime loss: Production stoppage loss caused by frequent replacement of accessories

2. "Non-mainstream" wisdom in core equipment selection

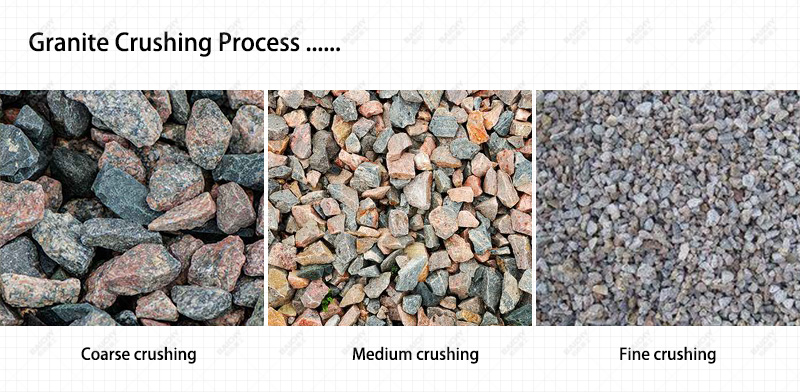

2.1 Coarse crushing stage: Jaw crusher is not the only choice

The traditional solution must be a jaw crusher, but we found that:

• Gyratory crusher is more cost-effective when the capacity is above 500t/h

• Heavy-duty vibrating feeder can replace traditional plate feeder, saving 15% energy consumption

• Hyperbolic jaw plate design can extend service life by 20% (patented technology)

2.2 Innovative combination in the medium and fine crushing stage

Break through the mindset of "cone crusher must be selected":

• High-pressure roller mill + vertical shaft impact crusher combination reduces energy consumption by 40% in the <3mm fine crushing stage

• The lamination crushing principle of multi-cylinder hydraulic cone crusher is more suitable for the characteristics of granite

The intelligent adjustment system can optimize the crushing chamber type in real time (latest technology)

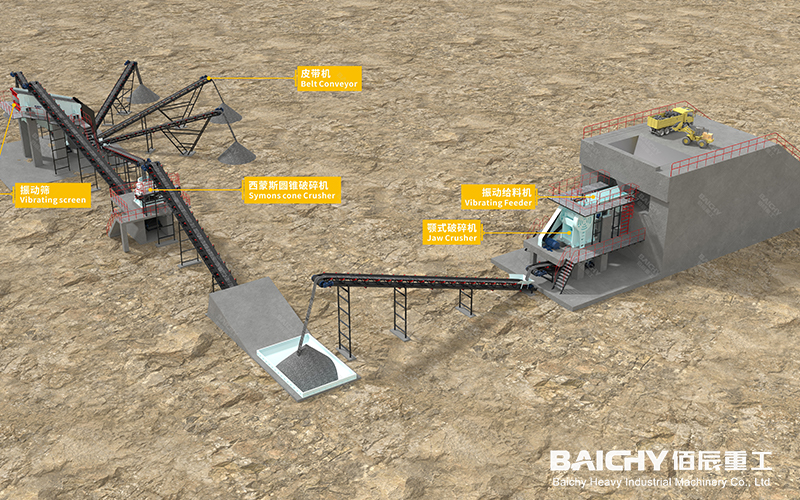

3. Spatial economics in production line layout

3.1 Subverting the traditional "Z" type layout

Different from the conventional linear layout, we recommend:

• Stepped drop design: Use gravity to reduce transportation energy consumption

• Strategic configuration of buffer bin: Set up buffer bins at key nodes to improve system stability

• Maintenance space reservation: Granite equipment requires a larger maintenance space (experience value: reserve 30% more)

3.2 Special considerations for dust removal system

Dust generated by granite crushing:

• High free SiO₂ content, requiring a wet method + bag dust removal composite system

• Dust removal air volume should be 25% higher than that of conventional production lines

• Pipes should be designed with wear-resistant linings

4. Key details in installation and commissioning

4.1 "Invisible standards" for foundation construction

• Concrete grade should be increased to C35 or above (conventionally C30)

• Anti-corrosion treatment of embedded parts: Granite crushing workshops have higher humidity

• Secondary grouting process: It is recommended to use non-shrinkage grouting material

4.2 "Run-in tips" during commissioning

No-load operation time is extended to 1.5 times that of conventional production lines

• Progressive feeding method: Starting from 30% load, increase by 10% every 8 hours

• Vibration monitoring: Install an online monitoring system to establish benchmark parameters

5. Underestimated operational optimization strategies

5.1 New ideas for wear-resistant parts management

• Mixed use scheme: Combination of linings of different brands can extend the life by 15%

• Flip and reuse: Cone crusher linings can be flipped four times (usually only twice in the industry)

• Laser cladding technology: Repair worn parts on site, saving 60% of costs

5.2 Hidden switch for energy consumption optimization

• Real-time adjustment of crushing chamber type: Automatic optimization according to material hardness

• Application of frequency conversion technology: The use of frequency conversion control in the conveying system can save 25% of electricity

• Heat recovery system: Utilize the heat energy generated by crushing (industry first solution)

Future trend of granite crushing

With the popularization of intelligent crushing and green mining concepts, granite crushing production lines are moving towards the direction of "three lows and one high" (low energy consumption, low wear, low emissions, and high intelligence). Investors are advised to pay attention to:

• Application of digital twin technology in production line optimization

• Breakthrough of ultra-hard composite materials in wear-resistant parts

• Integrated intelligent control system for crushing-screening-dust removal

Special reminder: There is no "standard answer" for granite production line configuration, and customized design is required based on specific ore source characteristics (such as crystal structure and weathering degree). It is recommended to conduct ore crushability tests before making decisions to avoid falling into the "empiricism" trap.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)