In the sand and gravel aggregate production industry, equipment selection directly affects the efficiency, cost and product quality of the production line. How to scientifically select key equipment such as crushers, sand making machines, screening equipment, etc.? How to optimize the production line configuration to meet environmental protection and high production requirements? This guide will systematically analyze the key points of equipment selection for sand and gravel aggregate production linesand provide practical suggestions to help you build an efficient, energy-saving and environmentally friendly sand and gravel production line.

1. Selection of core equipment for sand and gravel aggregate production lines

Jaw crusher

Applicable scenarios: primary crushing of high-hardness materials (such as granite and basalt).

Advantages: simple structure, easy maintenance, large feed particle size (≤1500mm).

Selection suggestion: Choose a hydraulic adjustment discharge port model to improve the degree of automation.

Gyratory crusher

Applicable scenarios: large sand and gravel production line (≥1000 tons per hour).

Advantages: large processing capacity, high crushing ratio, stable operation.

Selection suggestion: suitable for continuous high-intensity operation, but the investment cost is relatively high.

Comparison conclusion: jaw crusher is preferred for small and medium-sized production lines, and gyratory crusher is selected for large intensive production lines.

Medium and fine crushing equipment: cone crusher vs impact crusher

| Equipment type |

Applicable materials |

Crushing principle |

Finished product particle shape |

Energy consumption |

| Cone crusher |

High hardness rock |

Laminated crushing |

More needle-like |

Lower |

| Impact crusher |

Medium and low hardness rock |

Impact crushing |

Better particle shape |

|

Cone crusher: suitable for high-hardness materials, long life of wear-resistant parts, but slightly worse finished product particle shape.

Impact crusher: better particle shape, suitable for machine-made sand production, but the hammer wears faster.

Selection suggestion: If the main purpose is to crush stones, choose cone crusher; if high-quality machine-made sand is required, match the impact crusher to adjust the particle shape.

Sand making equipment: Key points for selecting vertical shaft impact crusher (sand making machine)

Key parameters:

• Feed particle size (usually ≤50mm)

• Impeller speed (high-speed crushing to increase fine powder rate)

• Shaping function (optimize particle size ratio)

• Trend of environmentally friendly sand making machine:

• Adopt closed structure + dust removal system to reduce dust pollution.

• Equipped with hydraulic cover opening device for easy maintenance.

2. Selection of auxiliary equipment and production line optimization

• Screening equipment: Selection of vibrating screen

Linear vibrating screen: suitable for dry screening, large processing capacity.

Circular vibrating screen: suitable for wet production, high screening accuracy.

Recommendation: multi-layer screen design (such as 3-4 layers) to improve classification efficiency.

• Feeder and conveying equipment

Vibrating feeder: ensure uniform feeding and avoid overloading of crusher.

Belt conveyor: choose wear-resistant belt to reduce maintenance cost.

• Environmental protection and noise reduction measures

Dust control: pulse bag dust collector is used, and the emission concentration is ≤20mg/m³.

Noise control: equipment foundation shock absorption + soundproof cover design.

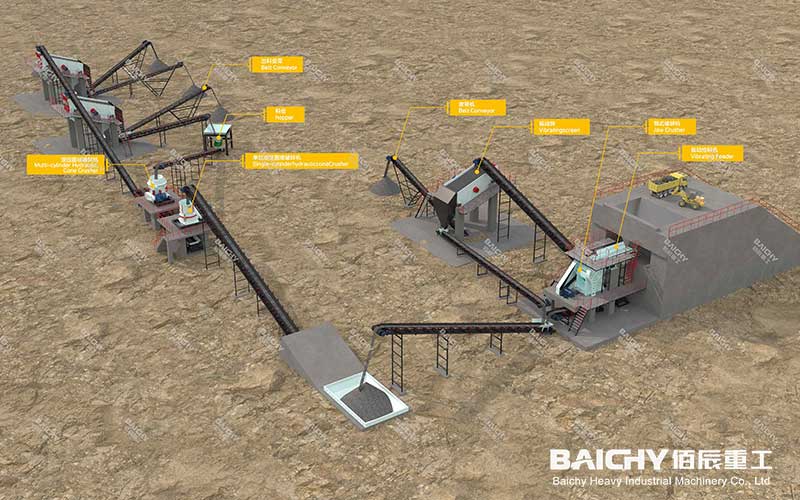

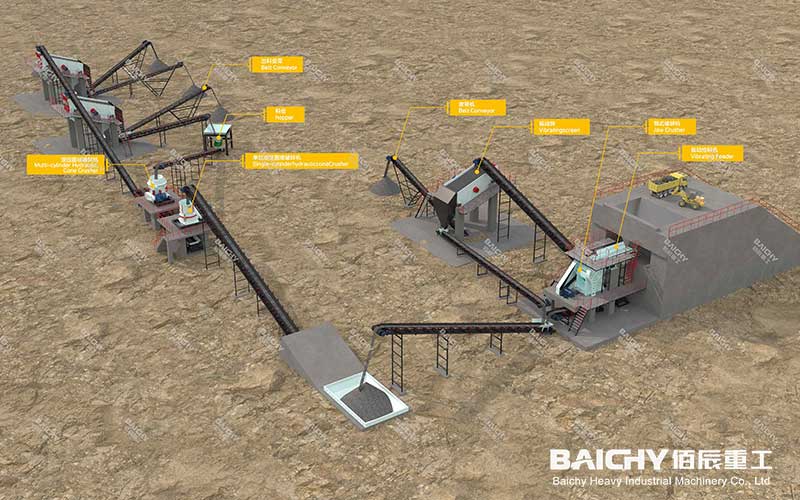

3. Production line configuration case reference

Case 1: 500 tons per hour granite crushing line

Process: jaw crusher (coarse crushing) → cone crusher (medium crushing) → vertical shaft sand making machine (fine crushing) → circular vibration screen (grading)

Features: three-stage crushing + closed-loop circulation, finished product rate ≥90%.

Case 2: Environmentally friendly limestone sand production line

Process: impact crusher (coarse crushing + shaping) → sand making machine → dust removal system + sewage treatment

Features: fully enclosed design, meeting green mine standards.

4. FAQ

Q1: How to reduce equipment wear costs?

Use high manganese steel wear-resistant parts and lubricate and maintain them regularly.

Avoid metal impurities from entering the crushing chamber.

Q2: What should I do if the production line capacity does not meet the standard?

Check the uniformity of feeding and the setting of the crusher discharge port.

Optimize the screen aperture to match the target particle size.

Q3: What points should be paid attention to in environmental protection acceptance?

The dust and noise monitoring data must comply with the "GB 3095-2012" standard.

Recycle wastewater to achieve zero emissions.

The selection of equipment for sand and gravel aggregate production lines needs to comprehensively consider material characteristics, production capacity requirements, environmental protection requirements and investment budget. It is recommended to give priority to equipment with modular design and intelligent control to meet future upgrade needs. If a customized solution is required, you can contact a professional engineer for one-to-one configuration optimization.

Further reading: