Potassium feldspar (KAlSi₃O₈) is a key raw material in the ceramics, glass, and building materials industries. Its powder fineness directly impacts product quality. With the growing demand for high-purity, ultrafine powders in the ceramics industry, potassium feldspar ceramic ball mill production lines have become key processing equipment.

1. Ceramic Industry: As a primary component of glazes and green bodies, it influences sintering performance and gloss.

2. Glass Manufacturing: It lowers melting temperatures and improves glass transmittance.

3. Chemical Filler: Used in industries like coatings and rubber to enhance product performance.

• Growing Demand for Ultrafine Powders: Potassium feldspar powders with a mesh size of 800 or higher are widely used in high-end ceramics.

• Energy-Saving and Environmentally Friendly Requirements: Grinding equipment with low energy consumption and low pollution levels is increasingly preferred. Production Line Process Flow

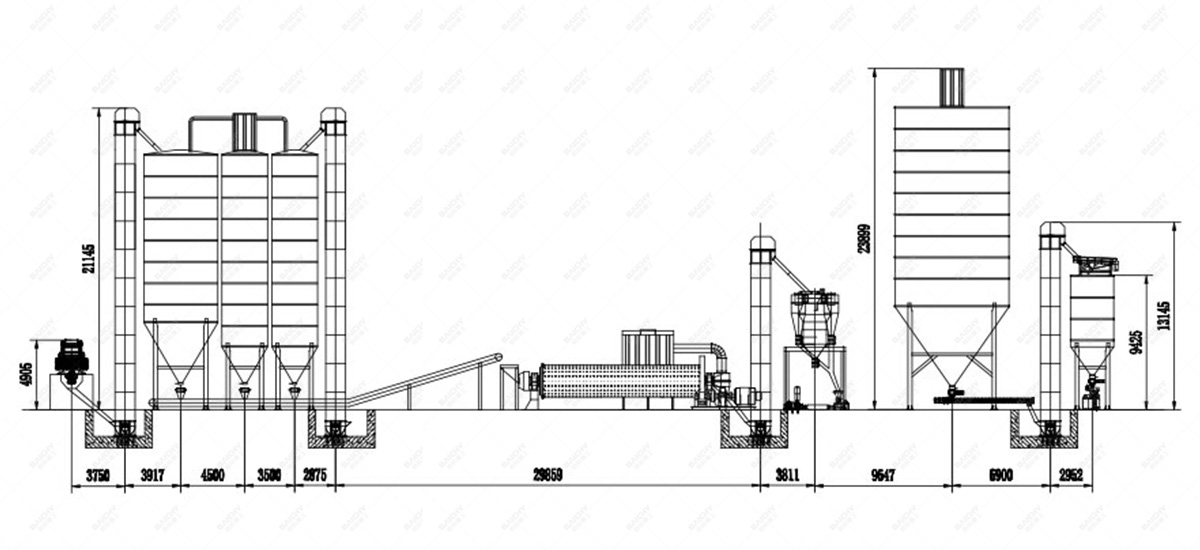

1. Coarse Crushing: A jaw crusher crushes the raw ore to ≤30mm.

2. Fine Crushing: An impact crusher or cone crusher further crushes the ore to ≤5mm.

3. Ball Mill Grinding: A ceramic ball mill grinds the ore to a mesh size of 80-2500.

4. Classification: An air classifier or vibrating screen controls fineness.

5. Collection: A pulse dust collector and cyclone collector ensure environmental compliance.

| Comparison Items | Ceramic Ball Mill | Conventional Steel Ball Mill |

| Wear Resistance | Alumina Ceramic Liner, Long Life | Steel Liner is Susceptible to Wear and Contaminates Materials |

| Fineness Range | 80-2500 Mesh Adjustable | Usually ≤ 800 Mesh |

| Energy Consumption | Energy Savings Over 30% | High Energy Consumption |

| Applicable Industries | Ceramics, Electronics, Chemicals | Building Materials, Metallurgy |

• Small Production Line: Φ1.5×3m ceramic ball mill, with a production capacity of 1-3 tons/hour.

• Large Production Line: Φ2.4×6m ceramic ball mill, with a production capacity of 8-15 tons/hour.

1. High-Purity Powder (Fe<0.05%)

Alumina/zirconia ceramic liners & grinding balls eliminate iron contamination,Ideal for high-end ceramics/electronics requiring ultra-low metal content

Integrated air classifier/vibrating screen ensures precise particle size control,D97 range covers all industrial needs from glazes to functional fillers

Optimized rotation speed/media ratio reduces power consumption by 15-20kW·h/ton,Cuts long-term operating costs significantly

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery