Wet pan gold mill (also known as wet gold mill, wet mill) is a wet grinding equipment specially used for gold ore dressing, mainly used for crushing, grinding and amalgamation of gold ore. It combines the functions of grinding, stirring and amalgamation, and is widely used in small gold ore dressing plants or laboratories, especially for processing gold-bearing quartz vein ore or placer gold ore.

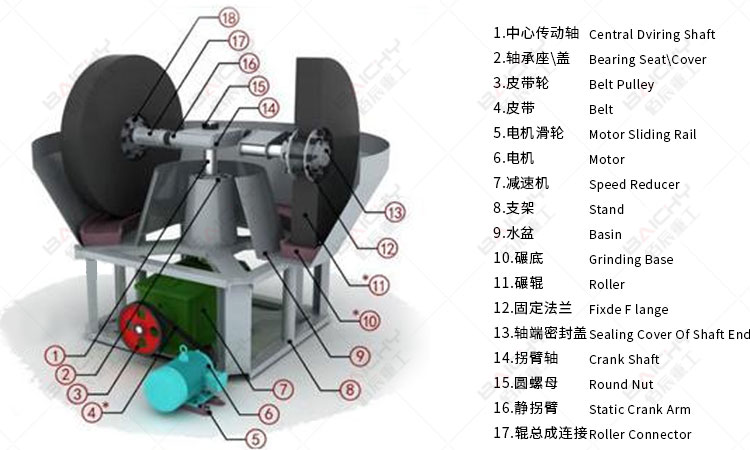

• Grinding pan: Made of cast iron or wear-resistant alloy, with grooves on the bottom to enhance the grinding effect.

• Grinding wheel: 1~3 heavy steel wheels (or alloy wheels) rolling on the grinding disc to crush the ore.

• Transmission system: The motor + reducer drives the grinding wheel to rotate, and some models can adjust the speed.

• Amalgamation device: Some models are equipped with mercury plates or amalgamation barrels for amalgamation recovery of gold.

• Water supply and drainage system: Provide water circulation, control the concentration of ore pulp, and facilitate the sedimentation of gold particles.

Wet Grinding Machine

Mining Wet Pan Mill

Pan Mill Price

Wet Grinding Machine

Gold ore dressing: Suitable for wet grinding and amalgamation of gold from placer gold and quartz vein gold.

Tailings reprocessing: Secondary grinding of old tailings to recover residual gold.

• Processing capacity: Select the diameter of the grinding plate according to the amount of ore (commonly 0.6~1.5m).

• Amalgamation requirements: If amalgamation is required for gold extraction, choose a model with a mercury plate or amalgamation barrel.

• Wear resistance: The grinding wheel and the grinding plate must be made of high manganese steel or alloy to extend their service life.

Wet pan gold mill is an important equipment for traditional gold extraction, especially for small-scale gold mines or laboratories. Although the amalgamation method has environmental problems, it is still widely used in some areas. In the future, with the improvement of environmental protection requirements, mercury-free wet grinding technology will become the development direction.

A wet pan mill is the best equipment to replace a ball mill because of its low investment, high output, easy use and maintenance, and quick cost recovery.

The wet grinding + amalgamation process can efficiently capture fine gold particles (less than 0.1mm), with a recovery rate of more than 90%.

It can be coarsely crushed (1~5mm feed) or finely ground to 0.1~0.5mm to meet the requirements of amalgamation or leaching.

Compared with the combination of ball mill + classifier, the wet disc gold mill can independently complete the whole process of crushing, grinding and amalgamation.

Under the same processing capacity, the purchase cost of the wet disc gold mill is only 1/3~1/2 of that of the ball mill.

Definition: Wet pan mill is a device that grinds and crushes materials using a water medium. It uses a disc and a millstone (or similar components) to process materials in a wet environment.

Working Principle: In a Wet pan mill, a certain amount of water is first added to the device, and then the material is put into the disc. Through the rotation of the disc and the action of gravity, friction, and impact are generated between the material and the abrasive (which may be a millstone or other form of abrasive), thereby achieving the effect of grinding and crushing. This wet grinding method helps to reduce dust generation, improve grinding efficiency, and facilitate further processing of the material.

| Model | 1600 | 1400 | 1300 | 1200 | 1100 | 1000 | 900 |

| Dia.of grinding wheel (mm) | 1600±10 | 1400±10 | 1300±10 | 1200±10 | 1100±10 | 1000±10 | 900±10 |

| Thickness of grinding wheel(mm) | 400±20 | 250±20 | 250±20 | 200±20 | 200±20 | 200±20 | 160±20 |

| Dia.of grinding pan (mm) | 2100±30 | 2000±30 | 2000±30 | 1800±20 | 1800±20 | 1800±20 | 1700±20 |

| Thickness of grinding pan (mm) | 200±10 | 170±10 | 150±10 | 90±10 | 90±10 | 90±10 | 80±10 |

| Width of grinding pan (mm) | 360 | 360 | 360 | 230-250 | 230-250 | 230-250 | 170-220 |

| Power (kw) | 30 | 15 | 15 | 7.5 | 5.5 | 5.5 | 3 |

| Rotary speed (r/min) | For extract gold: 10-13 other: 18-22 | ||||||

| Input size (mm) | < 30 | ||||||

| Capacity (t/day) | Gold 20 | Gold 20 | Gold 15 | Gold 10 | Gold 8 | Gold 5 | Gold 3 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery