|

Equipment |

ZSW960x3800 Vibrating feeder | PE600x900 jaw crusher | CS110/PYB1200 Cone crusher |4YK1860 Vibrating screen | Belt conveyor. |

|

Raw materials |

This stone-crushing plant can crush more than 120 kinds of ore materials such as limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size |

Less than 500mm |

|

Capacity |

100-150t/h |

|

Finished product |

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

|

Design requirements

|

1. The required production capacity 2. The type, hardness, and abrasiveness grade of the crushed material 3. The maximum size of the feed 4. The size of the desired final fraction |

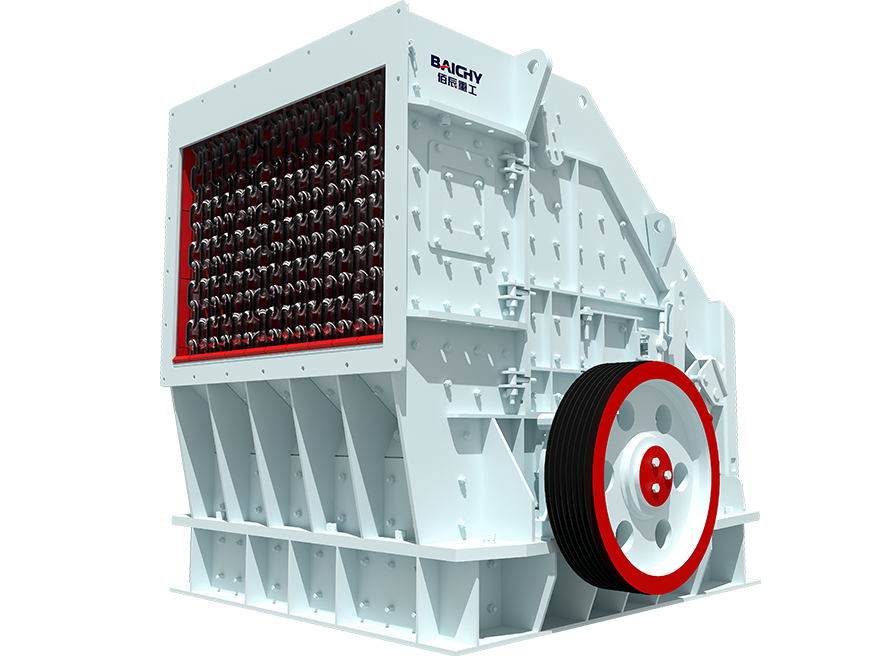

The CI series impact crusher is a highly efficient and energy-saving crushing equipment designed specifically for sand production and material shaping. It features a large feed size, high crushing efficiency, excellent product particle shape, and long service life of wear parts. It is widely used in various fields such as ore crushing, manufactured sand production, and construction aggregate processing.

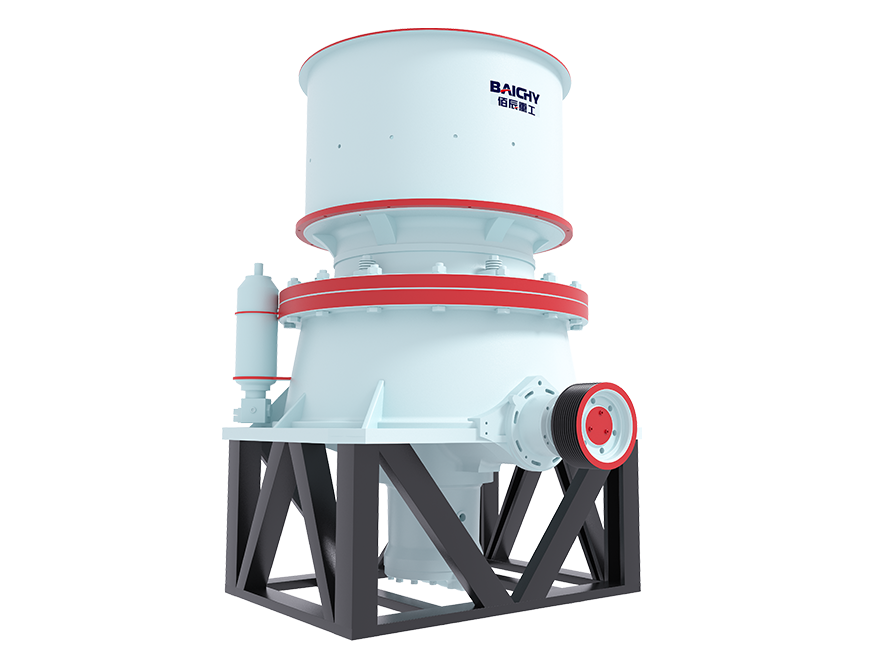

The Single-cylinder Hydraulic Cone Crusher is a high-efficiency crushing machine designed for secondary and tertiary crushing in mining, aggregates, and construction industries. With its simple structure, intelligent hydraulic control system, and low maintenance costs, it delivers reliable performance, high productivity, and energy savings compared to traditional multi-cylinder models.

PEX fine jaw crusher is a fine crushing model of jaw crusher, mainly used for medium and fine crushing of medium-hard materials (such as granite, basalt, limestone, etc.), suitable for mining, building materials, metallurgy, chemical industry and other industries. Compared with PE coarse jaw crusher, PEX model has finer material (usually 0-20mm adjustable), suitable for secondary crushing or fine crushing process.

Vibrating feeder → jaw crusher (coarse crushing) → impact crusher (medium crushing) → circular vibrating screen (grading) → finished product (0-5mm, 5-10mm, 10-30mm)

Features: low investment, low energy consumption, suitable for limestone, bluestone, and other medium and low hardness materials.

Vibrating feeder → jaw crusher (coarse crushing) → cone crusher (medium crushing) → impact crusher (sand making) → circular vibrating screen (closed loop)

Features: The finished product has excellent particle shape (needle-shaped ≤8%), suitable for sand making of high hardness materials such as granite and basalt.

Total crushing ratio: ≤40 (coarse crushing: medium crushing: fine crushing ≈ 4:3:3)

Discharge port adjustment: jaw crusher (80-150mm), cone crusher (25-50mm), sand making machine (3-10mm)

Screening closed loop: ≤150% (controlled by adjusting the screen size)

Conventional stone: 0-5mm (sand), 5-10mm, 10-20mm, 20-31.5mm

Sand and gravel mixture: powder content ≤10% (wheel sand washing machine is required)

PE600×900 jaw crusher: single machine processing capacity 100-150 tons/hour (adjusted according to material hardness, humidity, and feed particle size).

CS110/PYB1200 cone crusher: matching the crushing performance of a jaw crusher to ensure the stable operation of the whole line at 120-180 tons/hour (optimizable and adjustable).

Applicable materials: granite, basalt, iron ore, limestone, river pebbles and other medium and high hardness materials.

Not recommended materials: materials with excessive viscosity (such as wet clay) or excessive metal impurities may affect the life of the equipment.

Jaw crusher: Adjust the discharge port (65-160mm) through the gasket, and the material enters the cone crusher after coarse crushing.

Cone crusher: Hydraulically adjust the discharge port (3-60mm), and the final product can be controlled at 0-30mm (need to configure a vibrating screen for grading).

Jaw crusher: Motor power 75kW, low speed and high torque design, energy saving 15%than traditional models.

Cone crusher: Motor power 110- 132kW, laminated crushing technology reduces energy consumption, power consumption per ton ≤1.2kWh.

Minimum floor space: length × width ≥25m×15m (including silo, conveyor belt, screening equipment).

Recommended layout: jaw crusher (primary crushing) → vibrating feeder → cone crusher (secondary crushing) → circular vibrating screen (classification) → finished product conveying.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.