|

Equipment |

Vibrating feeder ZSW1100X4200 | C110 Jaw Crusher | CS220 Cone Crusher or PF1320 Impact Crusher | 4YK2470 Vibrating Screen | Belt Conveyor |

|

Raw materials |

350-450 t/hr stone crushing station can efficiently crush granite, limestone, basalt, pebbles ,and other hard rocks and construction waste, suitable for sand and gravel aggregates, mining and solid waste recycling. |

|

Feed Size |

0-700mm |

|

Capacity |

350-450t/h |

|

Finished product |

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

|

Design requirements

|

1.The required production capacity 2.The type, hardness, and abrasiveness grade of the crushed material 3.the maximum size of the feed 4.The size of the desired final fraction |

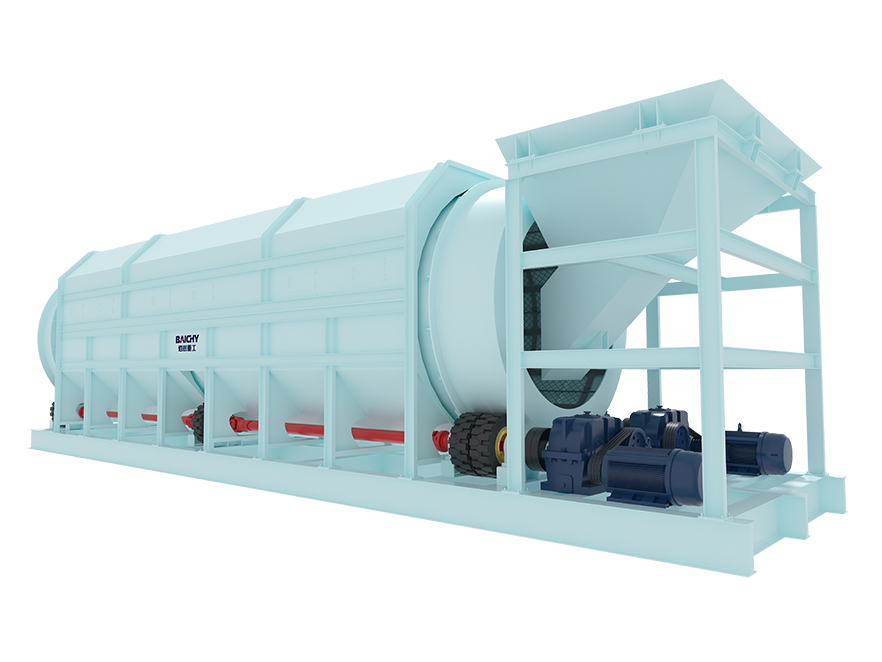

As a widely used screening equipment, the drum screen plays an important role in many fields due to its high efficiency, convenience, and environmental protection. The working principle is to control the sorting of materials based on the particle size.

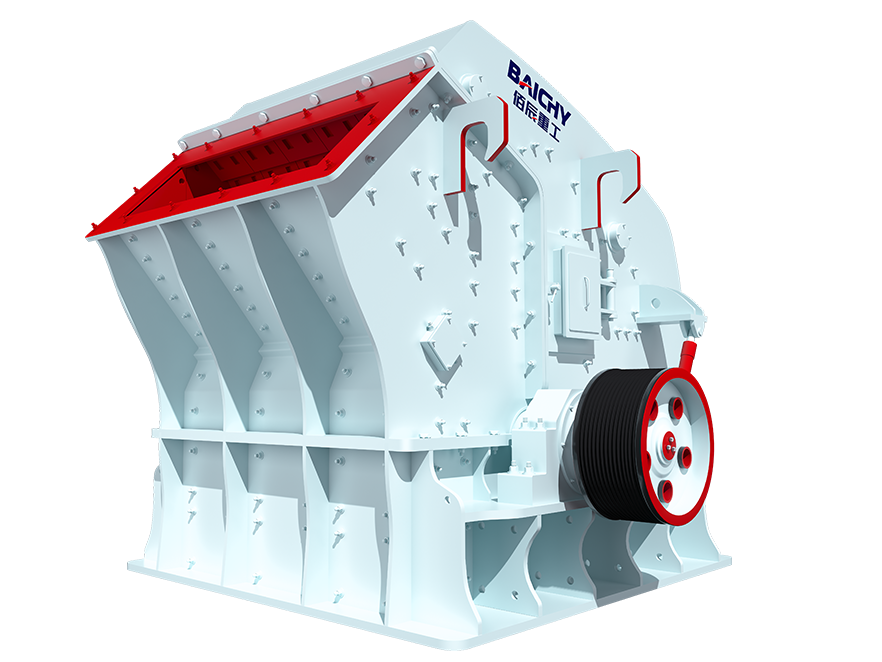

PF series impact crusher is a kind of equipment that uses the high-speed impact principle to crush various medium-hard materials with medium and fine crushing compressive strength not higher than 320Mpa, such as limestone, clinker, slag, coke, coal, etc.

Solve Your Primary Crushing Problems In One Go!

Baichy Heavy Industry's jaw crusher is specifically designed for crushing hard materials such as granite, basalt, and iron ore. We understand that stable primary crushing is the cornerstone of the entire production line.

Crushing line - jaw crusher

Crushing line - impact crusher

Crushing line - vibrarting screen

Amidst the wave of modern infrastructure development, 350-450 t/h fixed stone crushing plants have become core equipment for large-scale quarries and sand and gravel aggregate production companies. This high-capacity crushing equipment perfectly meets the following requirements:

• Continuous aggregate supply for large-scale engineering projects: Particularly suitable for national key projects such as highways, high-speed railways, and hydropower stations

• Economic benefits of large-scale production: Unit energy consumption is reduced by 15-20%, resulting in significant operating cost advantages

• Guaranteed high-quality finished products: A multi-stage crushing process ensures a standard particle size of 5-31.5mm and excellent particle shape

• Intelligent production management: An automated control system ensures 24/7 stable operation

• Primary crushing: C110 jaw crusher, with a maximum feed size of 1020mm

• Secondary crushing: CS220 Cone Crusher or PF1320 Impact Crusher (2 units)

• Screening equipment: 4YK2470 vibrating screens (2 units)

Further reading: How To Choose A Suitable Mining Stone Crusher? | 500 t/h Crushing Production Line Case

A: Our 350-450 t/h stationary crushing plants can efficiently process:

• Hard rock (compressive strength ≤ 300 MPa) such as granite and basalt

• Medium-hard stone such as limestone and dolomite

• Recycled aggregate from construction waste (special equipment required). Materials with high clay content (>15%) or excessive moisture (>8%) are not suitable.

A: The actual capacity depends on three key factors:

• Raw material characteristics: hardness, moisture content, and mud content

• Finished product requirements: Particle size distribution and particle shape standards

• Equipment configuration: Crushing ratio design and screening efficiency. Under standard operating conditions (medium-hard limestone, finished product 20-31.5mm), the actual capacity can reach over 95% of the nominal value. Equipment Selection Questions

The core advantages of a fixed crushing plant include:

• Processing capacity: The capacity of a single fixed crushing plant can be 3-5 times that of a mobile crushing plant.

• Operating costs: Energy consumption per ton is 15-20% lower, and wear-resistant parts have a 30% longer lifespan.

• Product quality: The multi-stage crushing process is more sophisticated, resulting in better particle shape control.

• Stability: Suitable for 24-hour continuous operation.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.