Mining screw conveyor is a continuous conveying equipment designed for mining, metallurgy, coal and other industries. It is mainly used to convey ore, slag, coal powder, tailings, and other abrasive and dense bulk materials. Its structure is strong and wear-resistant, suitable for harsh working conditions, such as high dust, high humidity, or a corrosive environment.

• Wear-resistant and durable: spiral blades and troughs are made of high manganese steel, wear-resistant alloy, or rubber lining to extend service life.

• Large conveying capacity: suitable for high-density materials (such as iron ore, copper slag), the conveying capacity can reach 100-500t/h.

• Sealed and dustproof: fully enclosed structure to reduce dust spillage and meet the environmental protection requirements of mines.

• Strong adaptability: horizontal, inclined (≤20°,) or short-distance vertical conveying to meet the layout requirements of underground or open-pit mines.

• Impact-resistant design: reinforced bearings and heavy-duty drive devices to adapt to the impact load of large pieces of ore.

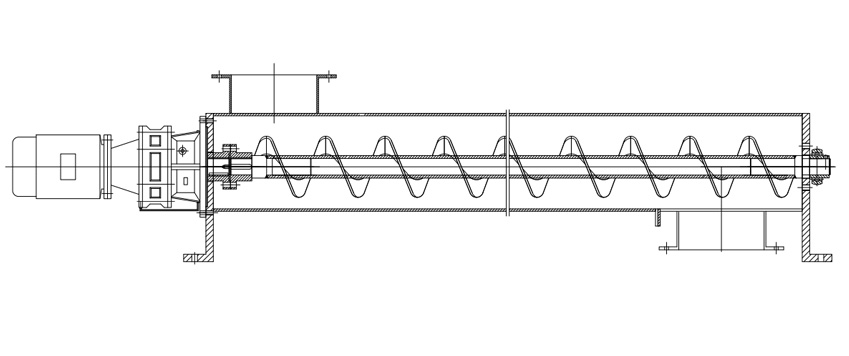

Structure Of Screw Conveyor

Horizontal Screw Conveyor

Screw Conveyor Price

Screw Conveyor Manufacturer

• Metal mines: conveying iron ore, copper ore powder, gold ore tailings, etc.

• Coal industry: conveying raw coal, coal gangue, and coal washing plant materials.

• Building materials industry: limestone, gypsum, cement raw materials, etc.

• Metallurgical industry: high-temperature materials such as blast furnace slag, steel slag, sintered ore, etc. (heat-resistant design is required).

• Material characteristics: particle size (≤1/2 spiral diameter), humidity, abrasiveness (such as quartz sand requires special wear-resistant treatment).

• Working conditions: underground operations require explosion-proof certification, and open-air environments require rain and rust prevention.

• Transportation parameters: transport capacity, inclination, length (usually ≤30m, long distances require multiple stages in series).

The screw conveyor is characterized by a simple structure, small cross-sectional size, good sealing, reliable operation, low manufacturing cost, convenient intermediate loading and unloading, and the conveying direction can be reversed or conveyed in opposite directions at the same time.

The spiral blades and trough body are made of high manganese steel, NM400 wear-resistant steel plate or rubber lining, which has a service life 3-5 times longer than ordinary carbon steel.

U-shaped trough or round tube design, with flange connection + sealing gasket, effectively suppresses dust spillage and meets the environmental protection requirements of mines (such as GB 16297 standard).

Horizontal, inclined (≤20°) or short-distance vertical transportation, suitable for narrow underground space or complex terrain of open-pit mines.

No complex transmission parts (such as belts, chains), only regular inspection of blade wear and bolt tightening is required.

The screw conveyor is mainly divided into three parts, the body of the screw conveyor, the entry and exit device, and the drive device. Among them, the screw body is mainly composed of a head section, middle section, tail section, screw shaft, and screw blades; the entry and exit devices are set at the head and tail of the machine according to the needs of customers; the driving device is composed of motors, reducers, couplings, etc.

The conveying process of the screw conveyor mainly relies on the driving device to provide power, and the screw bearing is connected by the coupling to move, the screw blade rotates with the bearing, and the material relies on friction to generate driving force with the casing and the screw blade, and is conveyed along the screw the bottom of the machine to move forward. And as the material continues to enter, the material that comes in later generates a certain thrust, which greatly reduces the power consumption of the screw conveyor during operation.

| Model | LSY165 | LSY219 | LSY273 | LSY325 | LSY425 |

|---|---|---|---|---|---|

| Diameter(mm) | 165 | 219 | 273 | 325 | 425 |

| Operation Angle | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 |

| Max length(mm) | 12 | 13 | 15 | 15 | 18 |

| Max capacity (ton) | 10 | 30 | 50 | 80 | 110 |

| Motor power(kw) | 2.2-15 | 2.2-22 | 3-22 | 5.5-22 | 5.5-22 |

https://www.baichychina.com/Powder/screw_conveyor.html

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery