Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

PE500×750 jaw crusher is a small and medium-sized coarse crushing equipment suitable for mining, quarrying, construction waste treatment, and other fields. With its simple structure, stable operation, and convenient maintenance, it has become the core equipment of many small and medium-sized crushing production lines.

✔ Efficient crushing: feed port size 500×750mm, maximum feed particle size ≤425mm, processing capacity 40-130 t/h, meeting the needs of small and medium-sized production lines.

✔ Sturdy and durable: high manganese steel jaw plate + high-quality cast steel frame, strong impact resistance, suitable for high-hardness materials such as granite and basalt.

✔ Energy saving and low consumption: optimize the motion trajectory of the movable jaw, reduce invalid stroke, and save 15%-20% energy compared to traditional jaw crushers.

✔ Flexible adaptation: can be matched with an impact crusher, cone crusher, or sand making machine to form a complete crushing and screening line.

• Cost-effective: Compared with large jaw crushers (such as PE600×900), the investment cost is lower, which is suitable for small and medium-sized enterprises with limited budgets.

• Easy maintenance: The lubrication system is optimized, the jaw plate is easy to replace, and downtime is reduced.

• Customized service: The motor power and protection level can be adjusted according to needs, and accessories such as wear-resistant plates and pulleys are provided.

| Model | PE500x750 |

|---|---|

| Feeder Opening Size(mm) | 500x750 |

| Max. Feeding Size(mm) | 425 |

| Outlet adjusting Size(mm) | 50-100 |

| Motor Power(kw) | 45 |

| Capacity(t/h) | 40-130 |

| Overall Dimension(mm) | 2150x1900x1950 |

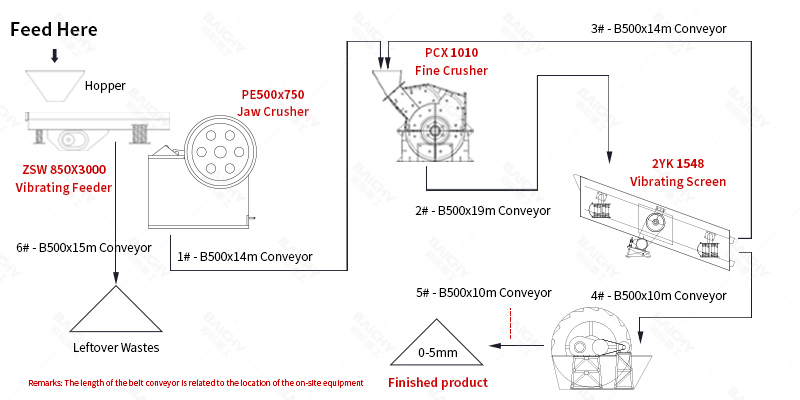

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW850x3000 | 1 |

| 3 | Jaw Crusher | PE500x750 | 1 |

| 4 | Fine Crusher | PCX1010 | 1 |

| 5 | Vibrating Screen | 2YK1548 | 1 |

| 6 | Sand Washer | XSD2160 | 1 |

| 7 | Belt conveyor | B500 | 6 |

The 80 t/h sand production line is specially designed for small and medium-sized sand and gravel aggregate production. It adopts the optimized combination of jaw crusher + high-efficiency fine crusher + vibrating screen + sand washing machine. It is suitable for the crushing and sand making of hard limestone, granite, basalt, river pebbles, smelting slag and other materials. It is widely used in hydropower engineering, building materials production, highway construction, urban transformation and other fields.

1. Primary crushing: Raw materials such as river pebbles are coarsely crushed by jaw crusher (river pebble crusher) to produce coarse materials ≤100mm.

2. Secondary fine crushing: The coarse materials are sent to the high-efficiency fine crusher through a belt conveyor and crushed into fine materials ≤30mm.

3. Screening and grading: The fine material enters the vibrating screen and is screened into two specifications:

• Qualified material (3-5mm) → sent to the sand making machine

• Oversize material (>5mm) → returned to the fine crusher for cyclic crushing

• The sand-making machine processes the gravel into 0-5mm machine-made sand;

• The sand washing machine (optional) removes dust from the sand and improves the quality of the finished product.

✔ High yield and energy saving: 80 t/h stable output, 20% energy saving compared to traditional processes;

✔ Flexible adaptation: The equipment model can be adjusted according to the characteristics of the raw materials (such as hardness and mud content);

✔ High quality finished products: The machine-made sand has rounded grains and continuous grading, which meets the GB/T 14684-2022 standard;

✔ Environmental protection and low consumption: closed design + pulse dust removal, dust emission ≤20mg/m³.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!