Heavy hammer crusher has the advantages of a simple structure, high crushing ratio, high production efficiency, etc. It can be used in both wet and dry working conditions and is widely applied in the industries of mining, cement, coal, metallurgy, construction materials, highway, chemical industry, etc.

In industries such as mining, building materials, and metallurgy, the choice of crushing equipment directly affects production efficiency and cost. Among many crushers, heavy-duty hammer crushers have become an ideal choice for coarse and medium crushing of bulk materials (such as limestone, bluestone, and coal gangue) due to their advantages such as high output, strong crushing force, and low maintenance cost.

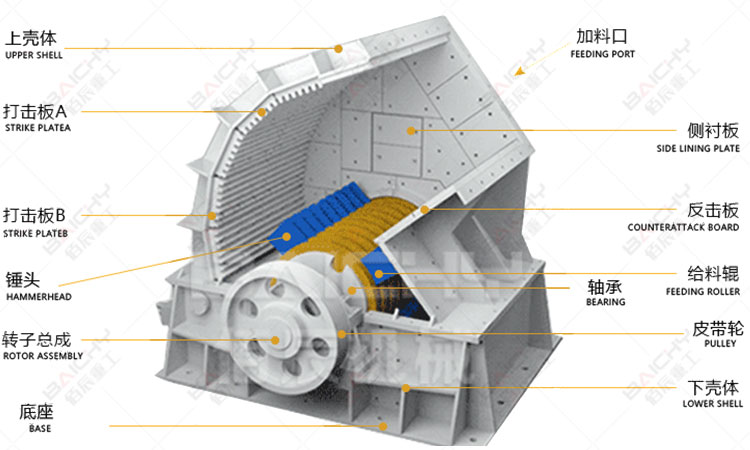

The core components of heavy-duty hammer crushers include:

• Heavy-duty rotor: driven by a high-torque motor to ensure stability under high-speed rotation.

• Wear-resistant hammer head: using multi-alloy composite casting technology, the head hardness reaches HRC62 or above.

• Hydraulic unpacking device: maintenance can be completed within 5 minutes, while traditional equipment takes more than 2 hours.

• Feeding stage: large pieces of material (≤1200mm) enter the crushing chamber.

• High-speed impact: The rotor drives the hammer to hit the material at a linear speed of 35-55m/s, achieving "hammering + shearing" double crushing.

• Screening control: Qualified particles are discharged through the grate bars, and oversized particles continue to be crushed.

"Crushing instead of grinding" trend: Modern heavy hammer crushers can achieve a fine crushing effect of ≤3mm, partially replacing traditional ball mills, and saving more than 30% energy.

Impact plate optimization: Some manufacturers use stepped impact plates to form "eddy current crushing" in the cavity to increase the fine powder rate.

Hammer Crusher

Large Hammer Crusher Price

PCZ Type Hammer Crusher Manufacturer

Hammer Crusher Model

After the material enters the crushing chamber, it is crushed by the high-speed rotating hammer head and collides with the impact liner to form "stone-on-stone" self-crushing. The qualified particle size is discharged through the bottom grate plate, and the large pieces of material continue to be crushed to the required size.

• Sand and gravel aggregate production line: primary crushing alternative

• Mining: save 25% power consumption compared with gyratory crusher

• Construction waste treatment: automatic steel bar separation design

• A cement group in Anhui: PCZ1820 processes limestone and runs continuously for 6,800 hours without failure

• Malaysia granite project: 3 PCZ1615s form a crushing system, and the investment return period is shortened by 40%

Heavy-duty hammer crusher is mainly applied in the industries of mines, metallurgy, building materials, road construction, railway building, water conservancy, cement, sand, coal, chemical engineering and electricity.

Large pieces of material (such as granite with a diameter of ≤1200mm) are thrown in from the feed port and instantly hit by the hammer on the rotor at a linear speed of 35-55m/s.

Impact force calculation: Assuming the hammer weighs 100kg and the rotation speed is 1200r/min, the kinetic energy of a single impact can reach 15,000 joules (equivalent to a 1.5-ton object falling from a height of 1 meter).

The material that has not been crushed once hits the serrated impact plate, and through rebound, it forms a "hedge crushing" with the subsequent hammer, thereby improving the fine crushing rate.

Industry skills: The angle of the impact plate is usually designed to be 30°-45°. The smaller the angle, the longer the material stays and the finer the finished particle size.

The crushed material is screened by the grate bars, and qualified particles (≤ set size) fall down, while oversized particles continue to be "reprocessed" by the hammer head.

Innovative design: Some high-end models use "wavy grate bars" to reduce the risk of blockage by increasing the screening area.

| Model | Feeding Size (W*L)(mm) |

Rotor Size (Dia.xL)(mm) |

Input Size(mm) | Power(KW) | Capacity(t/h) | Overall Dimension (mm) |

| PCZ0808 | 800 × 500 | Φ800 × 800 | ≤450 | 2 × 37 | 50-90 | 1760×1700×1540 |

| PCZ1308 | 850 × 800 | Φ1300 × 800 | ≤600 | 2 × 55 | 100-160 | 2818×2100×2390 |

| PCZ1310 | 1050 × 800 | Φ1310 × 1000 | ≤600 | 2 × 75 | 120-180 | 2818×2300×2390 |

| PCZ1510 | 1200 × 850 | Φ1500 × 990 | ≤700 | 2 × 132 | 160-210 | 3260×2370×2750 |

| PCZ1512 | 1200 × 1100 | Φ1500 × 1200 | ≤750 | 2 × 160 | 220-350 | 3260×2580×2750 |

| PCZ1615 | 1500 × 1300 | Φ1650 ×1500 | ≤1000 | 2 × 200 | 350-500 | 3456×2915×3185 |

| PCZ2016 | 1500 × 1400 | Φ2000 ×1500 | ≤1200 | 2 × 315 | 500-800 | 3880×2990×3560 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery