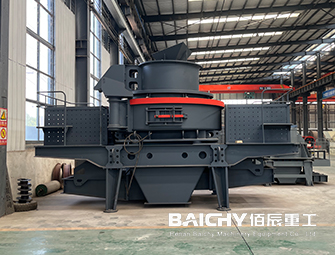

VSI sand-making machine has the advantages of high processing capacity, excellent finished sand shape, high wear resistance, easy maintenance, safety and reliability, and wide application fields. It is ideal sand-making equipment in construction, sand and gravel, cement, metallurgy, and other industries.

The VSI sand making machine, also known as the vertical shaft impact crusher, is a high-efficiency sand making equipment developed by our company by absorbing advanced domestic and international technologies and combining them with the specific working conditions of the domestic sand and gravel industry. It combines two crushing principles: "stone-on-stone" and "stone-on-iron," and has both crushing and shaping functions.

1. Feeding Hopper and Distributor: Achieves central feeding and annular waterfall feeding of materials, ensuring even distribution of materials.

2. Vortex Crushing Chamber: The core working area of the equipment. The structural design ensures that the material forms a dense material layer, achieving layered crushing and self-impact crushing.

3. Impeller Assembly: The core rotating component, made of high-strength materials, throws the material out at high speed. Its structural design directly affects processing capacity and crushing efficiency.

4. Main Shaft Assembly: Supports the impeller and transmits motor power. It uses a heavy-duty design and high-precision bearings to ensure stable operation.

5. Transmission Device: Usually uses a motor + belt drive or a direct-drive reducer to transmit power to the main shaft.

6. Base and Lubrication System: A sturdy base supports the entire equipment, and a thin oil lubrication station provides stable and reliable lubrication and cooling for the main shaft bearings.

7. Wear-Resistant Parts: Including wear plates, flow plates, throwing heads, wear blocks, etc., all made of high-performance wear-resistant alloys to protect the main body of the equipment and extend its lifespan.

8. Hydraulic Opening Device: The hydraulic system easily opens the top cover of the frame, facilitating quick inspection and replacement of wear-resistant parts inside the crushing chamber.

vertical shaft impact crusher, sand crusher, vsi sand-making machine

vertical shaft impact crusher, sand crusher, vsi sand-making machine

vertical shaft impact crusher, sand crusher, vsi sand-making machine

vertical shaft impact crusher, sand crusher, vsi sand-making machine

1. High-Quality Finished Products and Excellent Particle Shape: Using central feeding accompanied by annular waterfall feeding, the material undergoes multiple impacts and friction in the vortex crushing chamber. The resulting manufactured sand has a multi-faceted cubic particle shape, reasonable gradation, adjustable fineness modulus, and extremely low needle-like and flaky content, fully meeting the requirements of high-standard construction sand.

2. High crushing efficiency and low energy consumption: The optimized crushing chamber design and higher linear speed allow the material to gain higher kinetic energy within the chamber, achieving efficient self-impact crushing through stone-on-stone crushing. This results in high energy utilization and lower energy consumption compared to similar production capacities.

3. Multi-functional and flexible application: Through simple adjustments, it can switch between two working principles: stone-on-stone and stone-on-iron. Stone-on-stone is suitable for shaping and sand making of medium-hard and harder materials, with low wear costs; stone-on-iron is suitable for sand making of medium-hard and softer materials, with high crushing efficiency. It can also be used for fine crushing and shaping of coarse crushing products.

4. Easy maintenance and stable operation: The core crushing chamber components adopt a modular design for easy replacement. Key wear-resistant parts are made of high-strength wear-resistant alloy materials, ensuring a long service life. The hydraulic opening device makes internal inspection and maintenance quick and easy, effectively reducing downtime.

Vertical Shaft Impact Crusher is widely used in construction, roads, water conservancy, metallurgy, chemical industry, and other industries. In the construction industry, it is mainly used to produce sand for concrete, sand for dry-mixed mortar, etc. In road construction, it can be used to produce aggregates for road base and subbase; in water conservancy projects, it can be used to produce filling materials for embankments, revetments, and other projects. In addition, VSI sand-making machine is also suitable for crushing materials of various hardness and viscosity, such as river pebbles, granite, basalt, etc.

The sand-making machine is composed of seven parts: a feeding hopper, a distributor, a vortex crushing chamber, an impeller body, a main shaft assembly, a base, a transmission device, and a motor.

The material falls vertically into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal force, it will collide with another part of the material shunted around the impeller in the form of an umbrella. The material forms a vortex between the casings, collides and rubs each other many times, is crushed, and is directly discharged from the lower part to form a closed circuit for multiple cycles. After being controlled by the screening equipment, the finished product reaches the required particle size.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 490-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2278 | 5000*2700*3300 | 5100*2790*3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |||||

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw | ||||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | |||||

| Power of Oil-Box Heater | 2kw | |||||

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery