The fine sand recycling machine is mainly used for washing, dehydrating, and recycling the fine sand after the screening, which is simple and convenient.

Fine sand recycling machine is the development of equipment for the slurry material dehydration, disengagement, deslimatization , the machine biggest feature is a good solution to the sand industry of the problem of fine sand loss.

The fine sand recycling machine has multiple functions, which can efficiently clean, dehydrate and classify the fine sand, greatly reducing the mud, impurities, and moisture content in the sand. Compared with the traditional sand washing machine, its clea

The fine sand recycling machine has a reasonable structure, small footprint, simple installation, complete sand and gravel treatment at one time, strong operation stability, and high degree of automation.

The fine sand recycling machine is usually used after the circular vibrating screen or drum sieve, and the mixture of sand, water, and mud after screening is fed into the feeding end of the sand recycling machine, and finally, the sand is cleaned, dehydrated, and deslimed. The finished sand after fine sand dehydration has a water content of 14-16% and a mud content of less than 3.5%.

The fine sand recycling machine is mainly used for washing, dehydrating, and recycling the fine sand after the screening, which is simple and convenient.

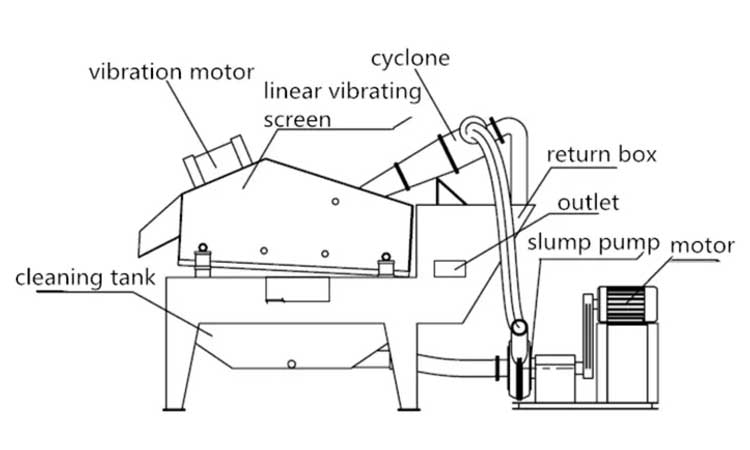

The fine sand recycling machine is composed of a dewatering screen, side liner, impeller separator, vacuum high pressure pump, cleaning tank, high return water tank, motor, and other components.

The sand-water mixture enters the cleaning box and is cleaned by the impeller separator. After the sand and mud are separated, the sand and gravel enter the lower dewatering screen for dehydration treatment, and the wastewater (containing a large amount of fine sand, mud, dust, and other impurities) flowing out of the cleaning box is processed by the vacuum high-pressure pump is transported to the high-pressure separator, and the fine sand after centrifugal classification is sprayed to the upper layer of the dewatering screen through the sand settling nozzle for dehydration treatment, and the remaining waste water, mud, dust, and other impurities are discharged through the high-level return water tank. Coarse sand is produced from the upper layer, and fine sand is produced from the lower layer or mixed with coarse and fine sand.

| Model | Pump Power (kw) |

Separator Spec (mm) |

Dewatering Screen | Capacity (m³/h) |

|

| Spec(mm) | Power (kw) | ||||

| FX250 | 11 | 250 | 800×2000 | 2×0.75 | 30-60 |

| FX300 | 15 | 300 | 800×2000 | 2×0.75 | 60-100 |

| FX350 | 18.5 | 350 | 1000×2000 | 2×1.5 | 70-130 |

| FX550 | 22 | 550 | 1200×3000 | 2×2.2 | 100-220 |

| FX650 | 30 | 650 | 1500×3000 | 2×3 | 120-272 |

| FX750 | 37 | 750 | 1500×3000 | 2×3 | 180-350 |

| FX900 | 55 | 900 | 1800×3600 | 2×4 | 450-650 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery