Raymond mill (or suspension roller mill) is an efficient and energy-saving dry grinding equipment. It adopts a vertical structure and annular grinding principle. The material is crushed to 80-600 mesh (0.175-0.044mm) through the rolling action of the grinding roller and the grinding ring.

Working principle: The material enters the grinding area through the feeder, and the grinding roller presses the grinding ring under centrifugal force to achieve the crushing effect. The fine powder is separated and collected by the airflow classifier.

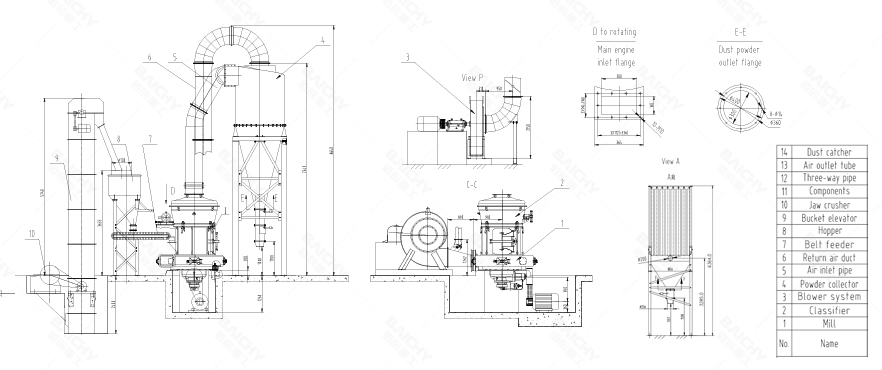

Typical structure: It consists of a main machine, an analyzer, a pipeline system, a cyclone powder collector, a motor, etc., and can be equipped with dust removal and noise reduction equipment.

Technical origin: It was invented by the Raymond Company in the United States in the early 20th century. After several upgrades, it has become the mainstream equipment for non-metallic mineral processing.

Raymond mill production line

Raymond mill host

Raymond mill roller

Roller working condition

Raymond mill is an efficient and energy-saving grinding equipment, which is widely used in non-metallic minerals, chemical raw materials, building materials, and other fields. Its core advantages are high fineness, low energy consumption,n and stable operation. It is suitable for non-flammable and explosive materials with Mohs hardness ≤7 and humidity ≤6%.

In the mining field:the equipment can efficiently process non-metallic minerals such as limestone and barite, and provide high-quality auxiliary materials such as bentonite and fluorite for the metallurgical industry, and realize the refined utilization of coal resources.

In the field of chemical manufacturing:Raymond mill can accurately control the particle size distribution of fine chemical raw materials such as titanium dioxide and calcium carbonate, and provide reliable support for the production of rubber fillers and agricultural fertilizers.

The building materials industry :relies on this equipment to produce high-performance cement additives, ceramic raw materials and refractory materials, significantly improving product quality.

In the papermaking coating industry: Raymond mill effectively improves the gloss of paper and the hiding power of coating products by processing fillers such as calcium carbonate and talcum powder.

• Multi-roller crushing, energy consumption is 30%~40% lower than that of a ball mill

• Closed-circuit design avoids over-crushing, and the utilization rate of electricity is increased by 20%+

• The power consumption per ton is only 40~50 kWh (325 mesh calcium carbonate), which saves 50% more electricity than air flow mill

• Frequency conversion classifier, fast adjustment of 80~600 mesh, no need to change the screen

• Applicable to minerals with Mohs hardness ≤7 (limestone, talc, etc.)

• Special models can be expanded to 2500 mesh (5μm)

• Modular design, independent maintenance of key components

• Wear-resistant parts lifeof 5000~8000 hours (alloy/ceramic material)

• PLC intelligent monitoring, automatic alarm

• Fully enclosed negative pressure operation, dust emission 30mg /m³ (national standard 50)

• Low noise (≤80dB),suitable for urban areas

• Optional explosion-proof configuration (nitrogen protection + explosion-proof valve)

Step 1 The raw material is crushed into a specified particle size by the jaw crusher, lifted to the hopper by the bucket elevator, and then quantitatively sent to the crushing chamber by the feeder.

Step 2 A rotating shovel scoops up the ingredients and projects them between the rollers and the ring where the grinding takes place.

Step 3 The pulverized powder is blown into the classifier by the air blower for classification. Oversized particles fall into the grinding chamber for regrinding. Qualified powder flows into the cyclone collector through the classifier and is collected as finished product.

Step 4 To ensure that the Raymond mill works under negative pressure. The increased air flow enters the pulse dust collector through the pipeline, and is discharged into the atmosphere after purification. The dust-free operation in the workshop is realized through the pulse collector.

| Model |

Roller (pcs) |

Roll Dia. (mm) |

Roll Ring Size (mm) |

Max. Input Size (mm) |

Output Size (mm) |

Capacity t/h |

Power (Kw) |

Dimension (mm) |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 0.4-1 | 15 | 3500*3300*4500 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 0.5-2 | 18.5 | 4650*3600*5100 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 0.8-3 | 22 | 4700*3600*5100 |

| 4R3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 1-4 | 30 | 5400*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 1.8-4.5 | 37 | 7100*5900*7900 |

| 5R4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 2.5-9.5 | 75 | 9200*7250*9700 |

Raymond Mill is suitable for non-metallic minerals with Mohs hardness ≤ 7, such as limestone, calcite, barite, talc, kaolin, gypsum, fluorite, etc. It is not suitable for sticky materials (such as wet clay) or superhard materials (such as silicon carbide).

The standard model can produce 80~600 mesh (0.175~0.044 mm), and the improved grading system can be expanded to 2500 mesh (5μm).

The output of a single machine is 1~50 tons/hour, depending on the material hardness, fineness requirements, and equipment model.

When Raymond mill processes 325 mesh calcium carbonate, the power consumption per ton is about 40~50 kWh, which is 30%~40% more energy-saving than ball mill and more than 50% more energy-saving than air flow mill.

The main wearing parts of Raymond mill are the grinding roller and the grinding ring. When made of wear-resistant alloy or ceramic material, the service life can reach 5000~8000 hours (about 2~3 years).

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery